Connection

7.2 Electrical connection

SIMOTICS M-1FE2 built-in motors

Hardware Installation Manual, 04/2020, A5E50074509B AA

145

Guidelines for power connection

Also observe the following notes for providing the power connection:

● Lead the cable ends through the flexible tube or cable duct.

● Keep the inside of the terminal box clean and free from trimmed-off ends of wire.

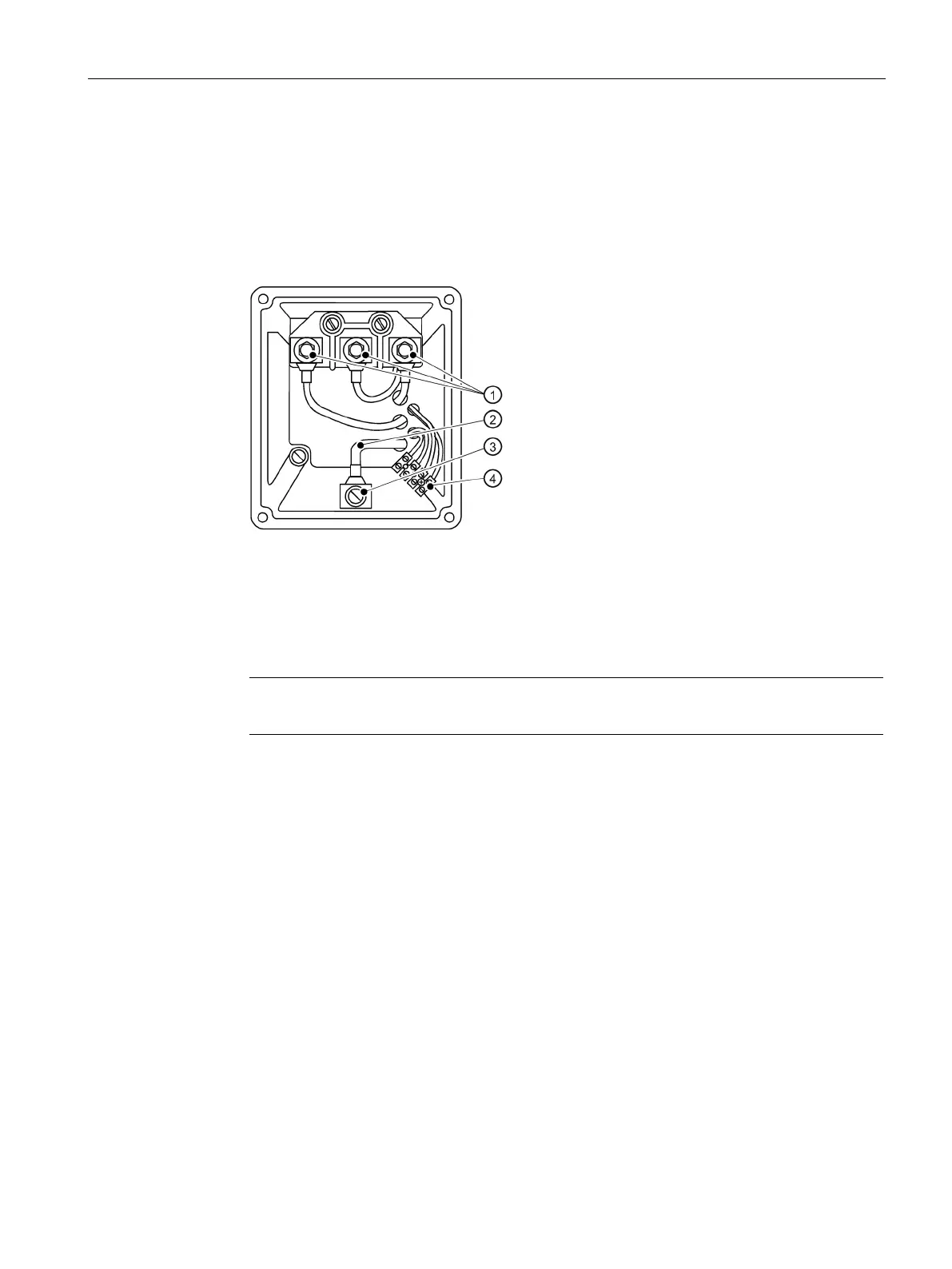

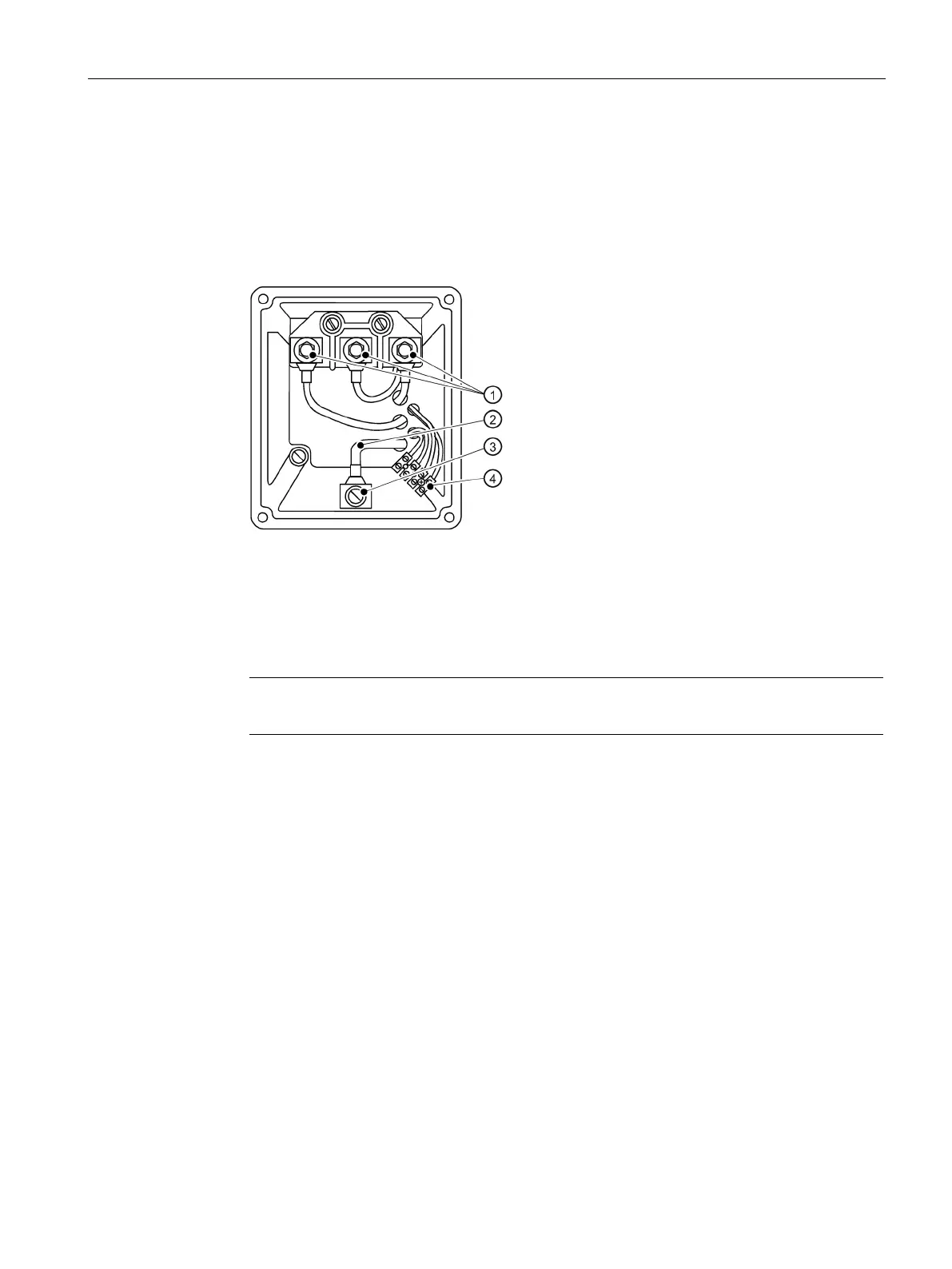

● See the following diagram for an example of terminal box design

Power connections (according to DIN 46200 can only be used in the motor spindle)

Internal protective conductor

Ground connection for internal and external protective conductors

Connectors for temperature sensors

Figure 7-2 Terminal boxes with permanent (internal) star connection (example)

Note

Connect the cables in accordance with project specifications of the

spindle manufacturer.

7.2.8 Information on cable routing

● Lay loose connection cables so that the insulation is not damaged.

● Make sure that the minimum bending radii are not exceeded. Minimum radius for fixed

installation: R = 4 x D

(D = outer cable diameter).

● Only remove insulation from the cable ends so that the insulation reaches up to the cable

lug, terminal, or wire end ferrule.

● Use cable lugs or wire end ferrules appropriate for the dimensions of the terminal board

connections and the cable cross-section. If necessary, install parallel connection cables.

● Ensure that the inside of the terminal box or connector is clean and free of cable cuttings

and moisture.

● Tighten all of the screws for the electrical connections (terminal board connections, with

the exception of the terminal strips) to the torque specified by the spindle manufacturer.

Loading...

Loading...