Motor components, characteristics and options

4.2 Cooling

SIMOTICS M-1FE2 built-in motors

Hardware Installation Manual, 04/2020, A5E50074509B AA

73

4.2.7 Coolant

Coolant specification

As coolant, use only water that complies with the "water specification for coolant".

Note

If possible, use deionized water with reduced conductivity (5

... 10 μS/cm) as the coolant.

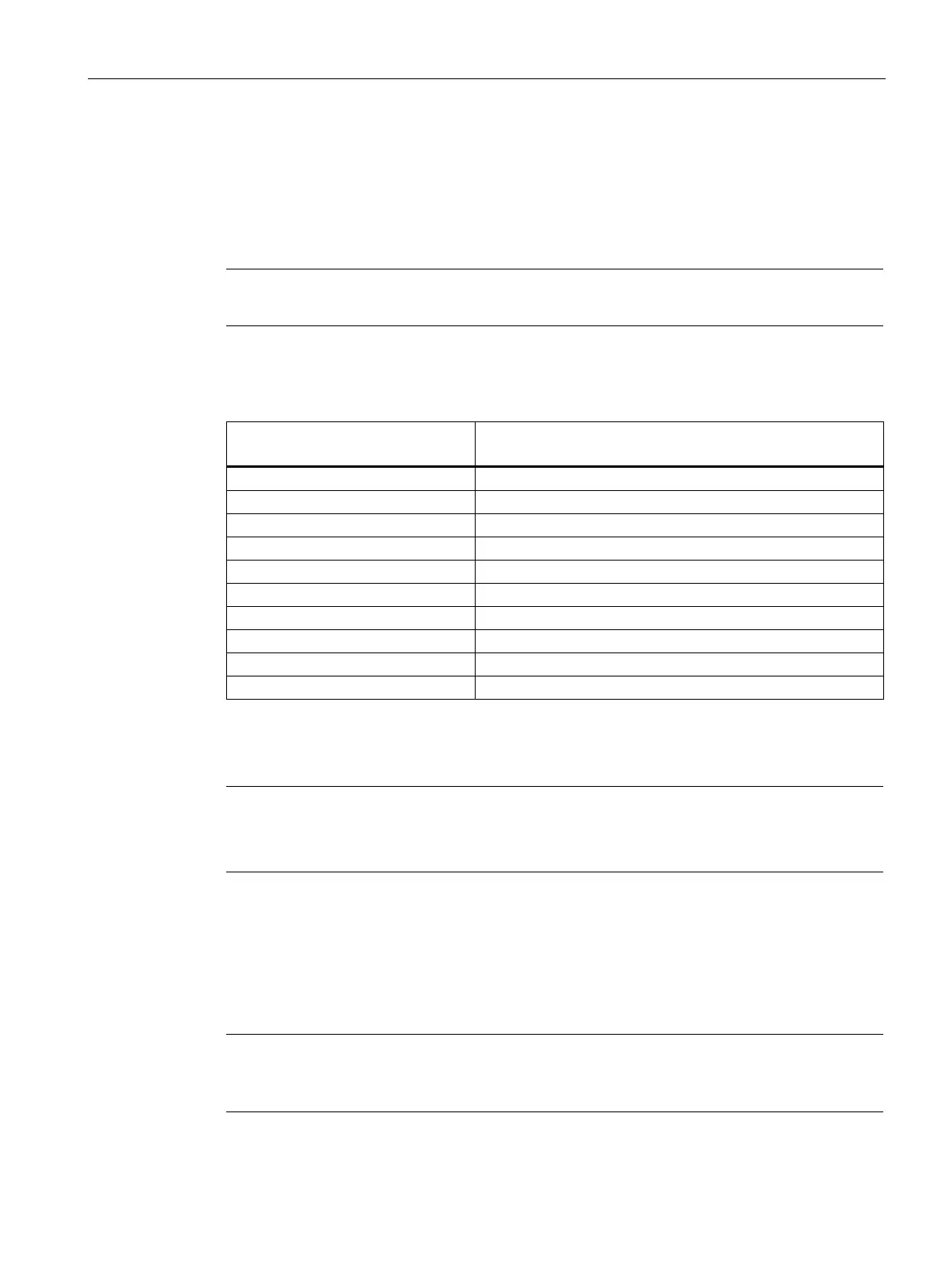

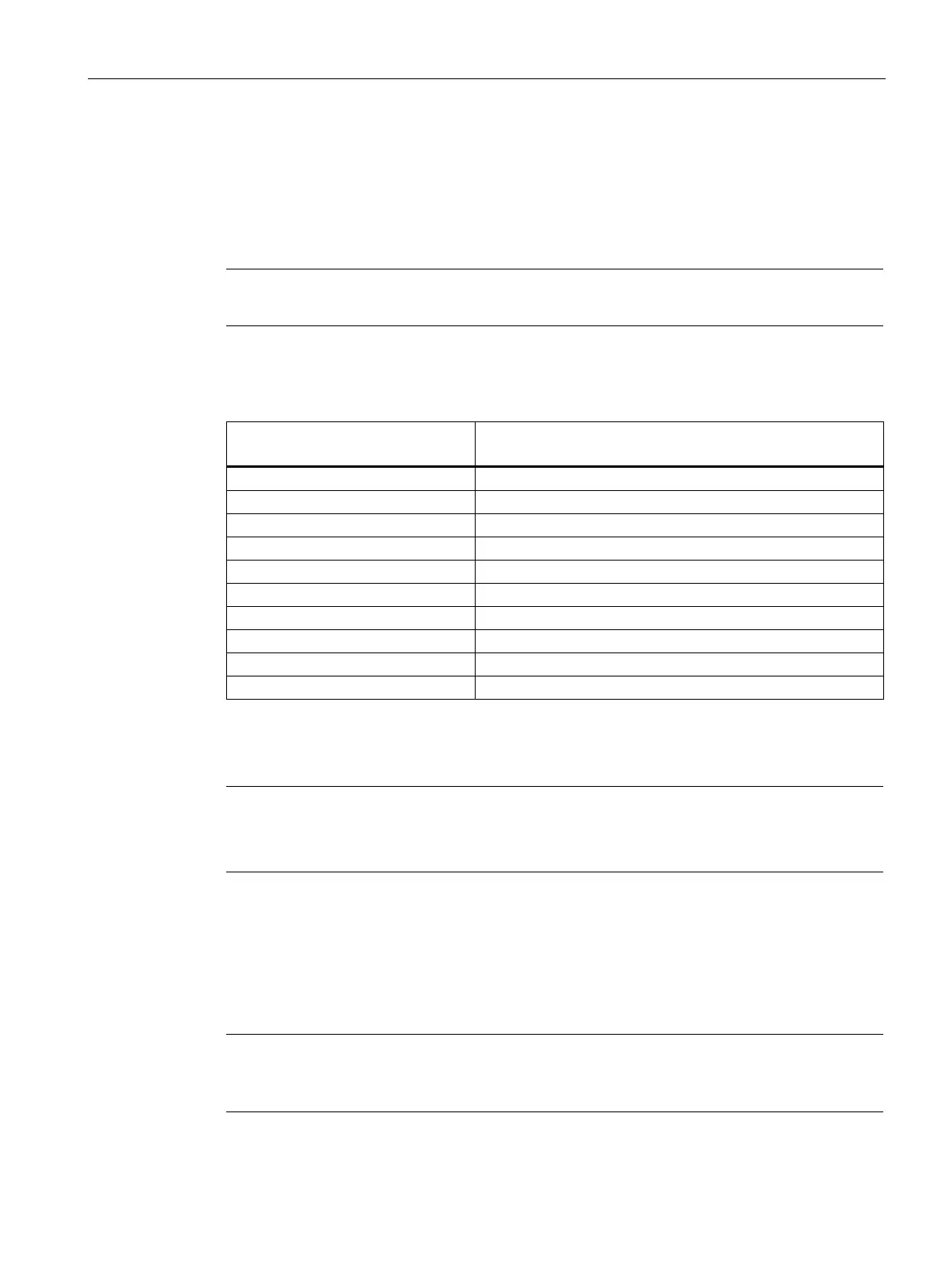

Table 4- 9 Coolant water specifications

Quality of the coolant water for motors with a cooling jacket

manufactured out of steel or aluminum

< 40 ppm, can be achieved by adding deionized water.

For steel: 6 ... 9; for aluminum: 6 ... 8

Size of entrained particles

0.2 to 0.25% inhibitor, Nalco TRAC100 (previously 0GE056)

When required, 20 - 30% Tyfocor

The values specified for the water as a coolant are the requirements for a closed cooling

circuit. Not all of the specified concentrations will occur in the water at the same time.

When necessary, contact your water utility for the values.

Note

Inhibitor is not required if

a Tyfocor concentration > 20% is ensured.

Derating is not required for antifreeze protection components < 30%.

Measures for frost danger

If there is danger of frost, adopt frost protective measures for complete or preassembled

motor spindle units.

● Replenish antifreeze for operation (see Table "Coolant water specifications").

Avoid mixing different antifreeze products.

Use and dose the antifreeze according to the manufacturer’s specifications.

Loading...

Loading...