Description

3.3 Technical features and system requirements for built-in motors

SIMOTICS M-1FE2 built-in motors

38 Hardware Installation Manual, 04/2020, A5E50074509B AA

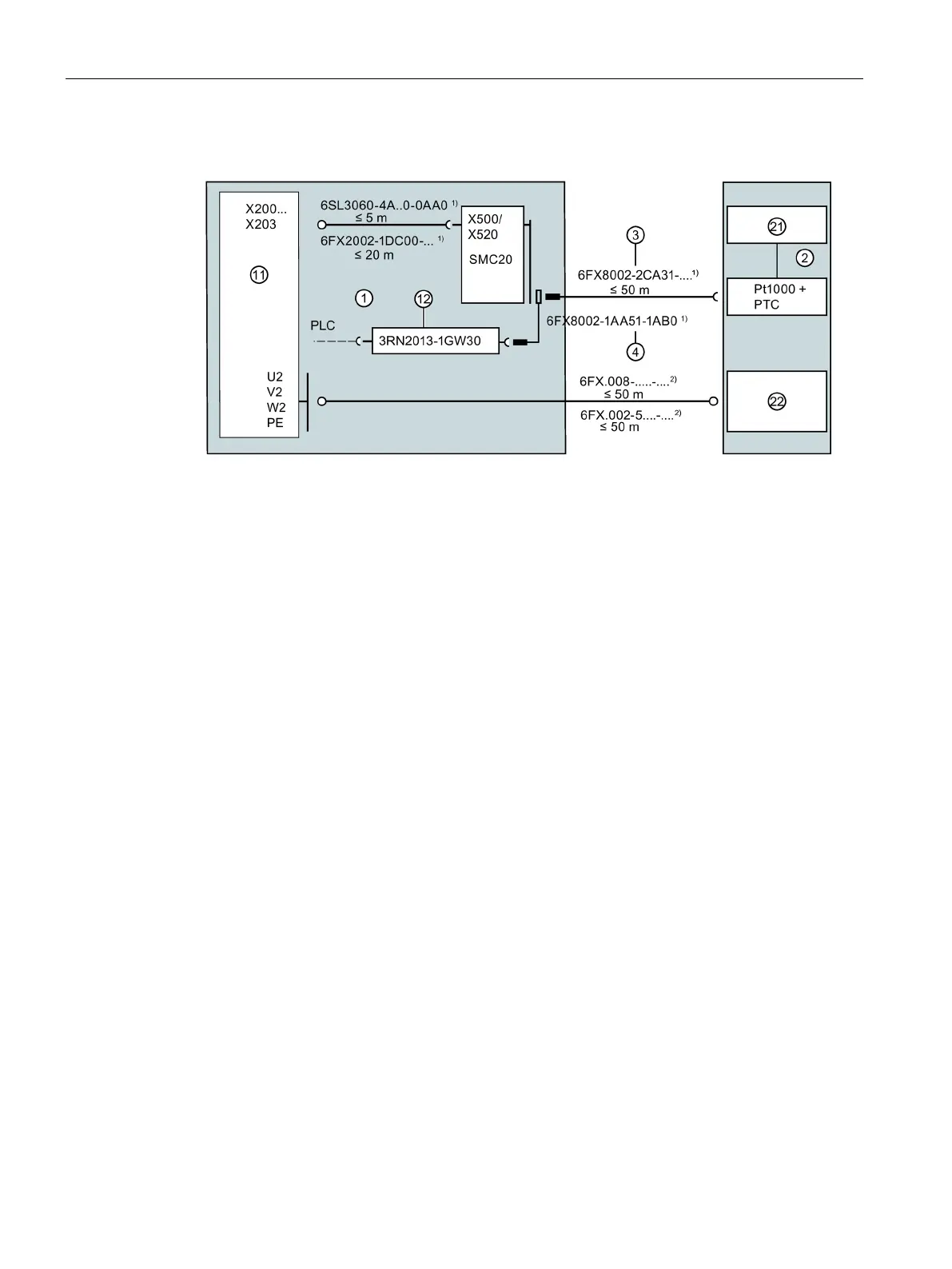

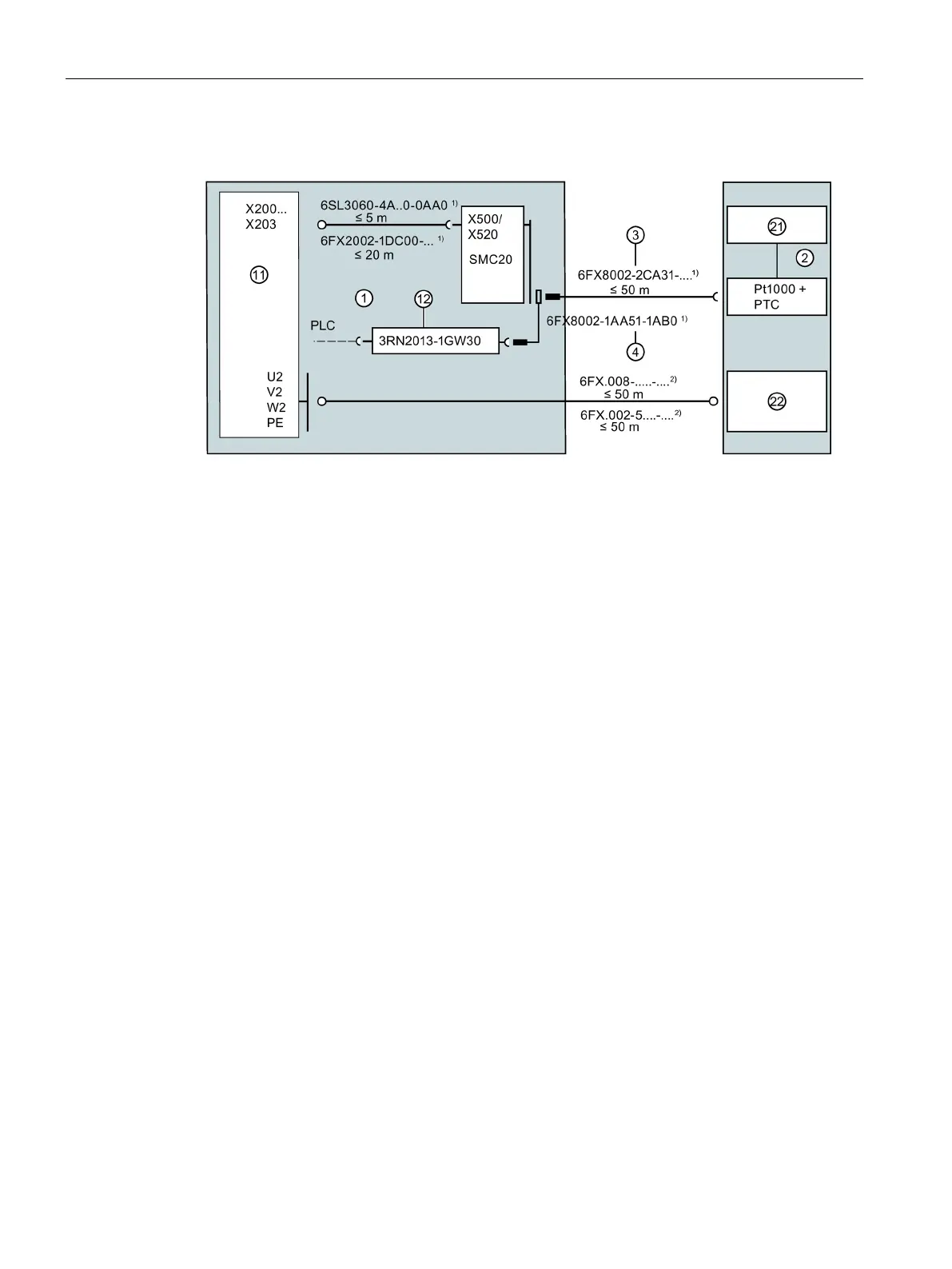

Motor with full protection, integrated into the system via SMC20

1)

Article numbers for prefabricated

MOTION-CONNECT signal cables, M23

connector size

2)

Article numbers for prefabricated

MOTION-CONNECT power cables

≲ 25 m in the case of star-delta changeover in

1 Control cabinet 21 Incremental encoder sin/cos 1 Vpp or EnDat

11 SINAMICS S120 Motor Modules, Booksize

format, DRIVE CLiQ communication via

22 1FE2 winding, connection via terminal box

12 Tripping unit 3 Signal cable for encoder and temperature

sensor,

17-pin M23 round connector

2 1FE2 built-in motor

4 Signal cable for PTC via tripping unit

3.3.4 Version and operating modes of the motor in the synchronous version

1FE2 motors of shaft height 180 (1FE218☐) consist of two winding systems, i.e. each motor

has six connecting cables (three connecting cables for each winding system).

Both partial windings are galvanically separated and only weakly coupled magnetically.

This means the motors can be operated in two different ways.

Option 1: Connection of the two windings to one (large) power section and the "classic"

operation of the motor on a CU/NCU.

Loading...

Loading...