Commissioning

8.3 Checklist prior to commissioning

SIMOTICS M-1FE2 built-in motors

Hardware Installation Manual, 04/2020, A5E50074509B AA

169

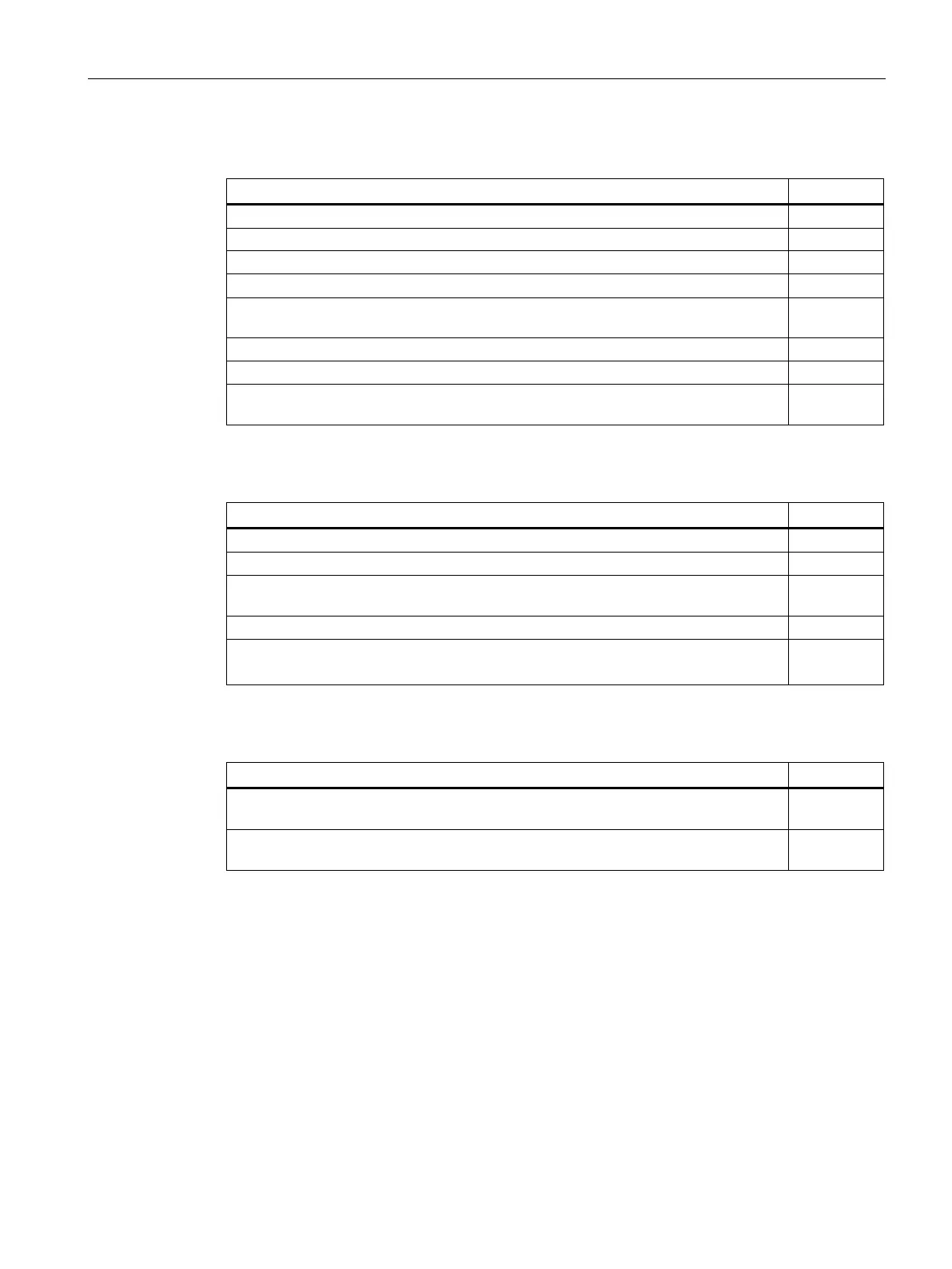

Checklist (2) - checks regarding the mechanical system

Do all touch protection measures for moving and live parts function properly?

Has the motor been correctly mounted and aligned?

Can you rotate the rotor without it touching the stator?

Do the operating conditions correspond to the data specified on the rating plate?

Are all mounting screws, connecting elements, and electrical connections tightened

with the prescribed torques and properly attached?

Do the output elements have the right setting conditions?

Is the rating plate visible and fastened permanently on the spindle box?

Have further specific spindle tests (e.g. balancing) been performed in accordance with

spindle manufacturer's specifications?

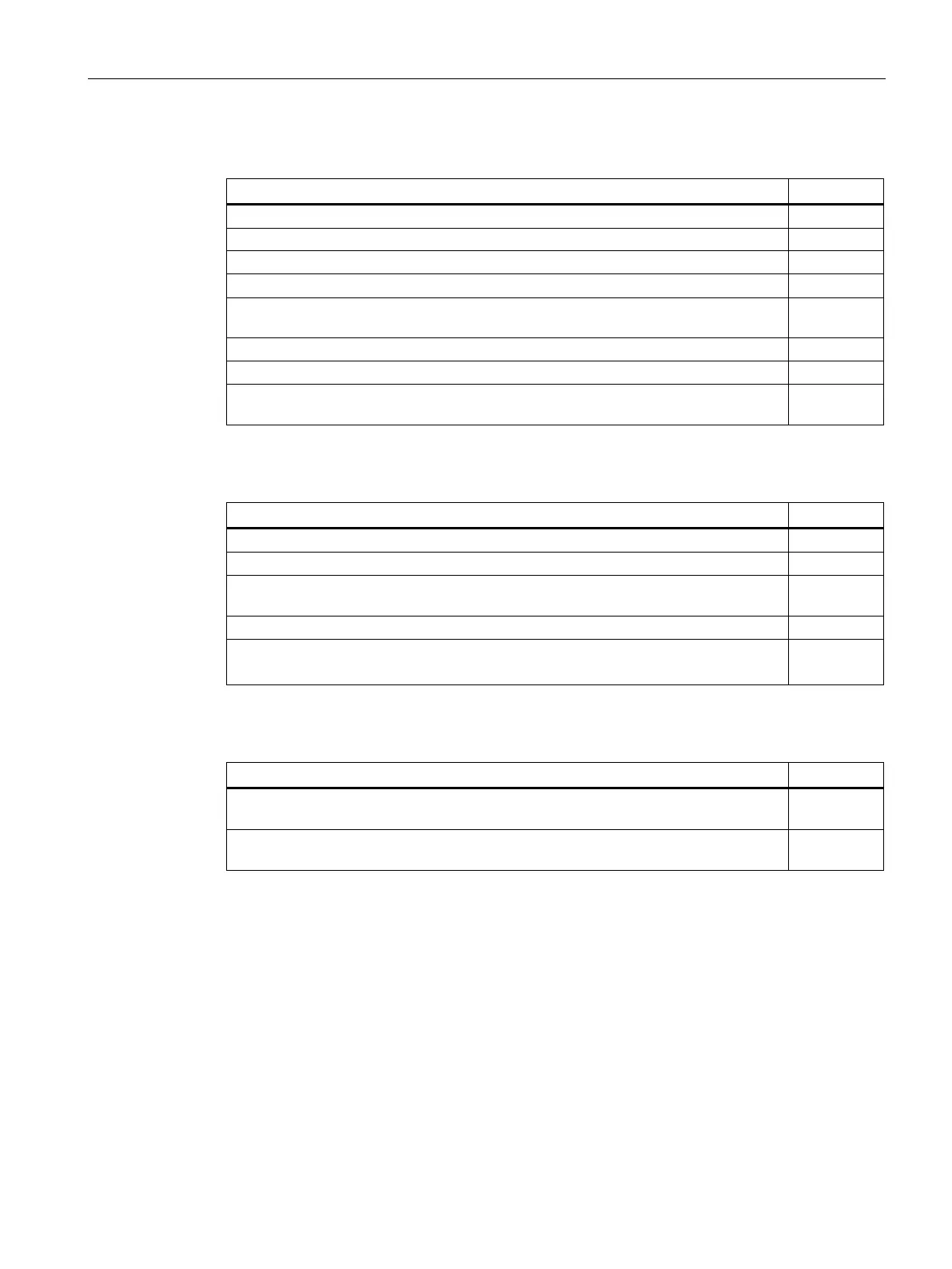

Checklist (3) - checks regarding the electrical system

Has the motor been connected so that it rotates in the specified direction?

Have the minimum insulation resistance values been maintained?

Have the grounding and equipotential bonding connections been established correct-

Is the specified limit speed n

max

maintained during the operation on the converter?

Applies only to the asynchronous version with external star-delta changeover:

Are the contactors and auxiliary contacts correctly wired and parameterized?

Checklist (4) - Monitoring equipment checks

Has it been ensured that no speeds higher than the maximum speed n

max

can be

Have all supplementary motor monitoring devices been correctly connected and are

Loading...

Loading...