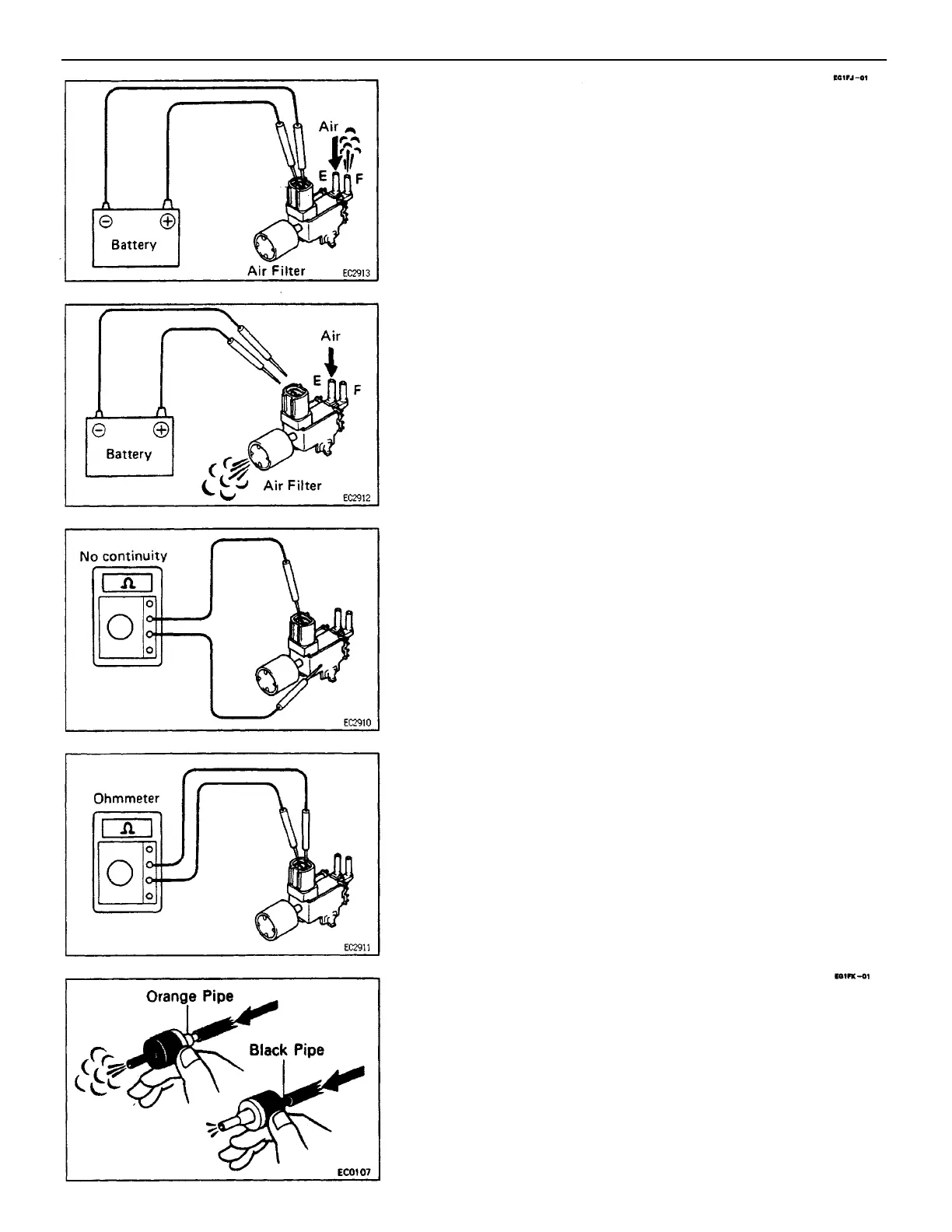

VSV INSPECTION

1. CHECK VACUUM CIRCUIT CONTINUITY IN VSV BY

BLOWING AIR INTO PIPE

(a) Connect the VSV terminals to the battery terminals as

illustrated.

(b) Blow air into pipe E and check that air comes out of

pips F.

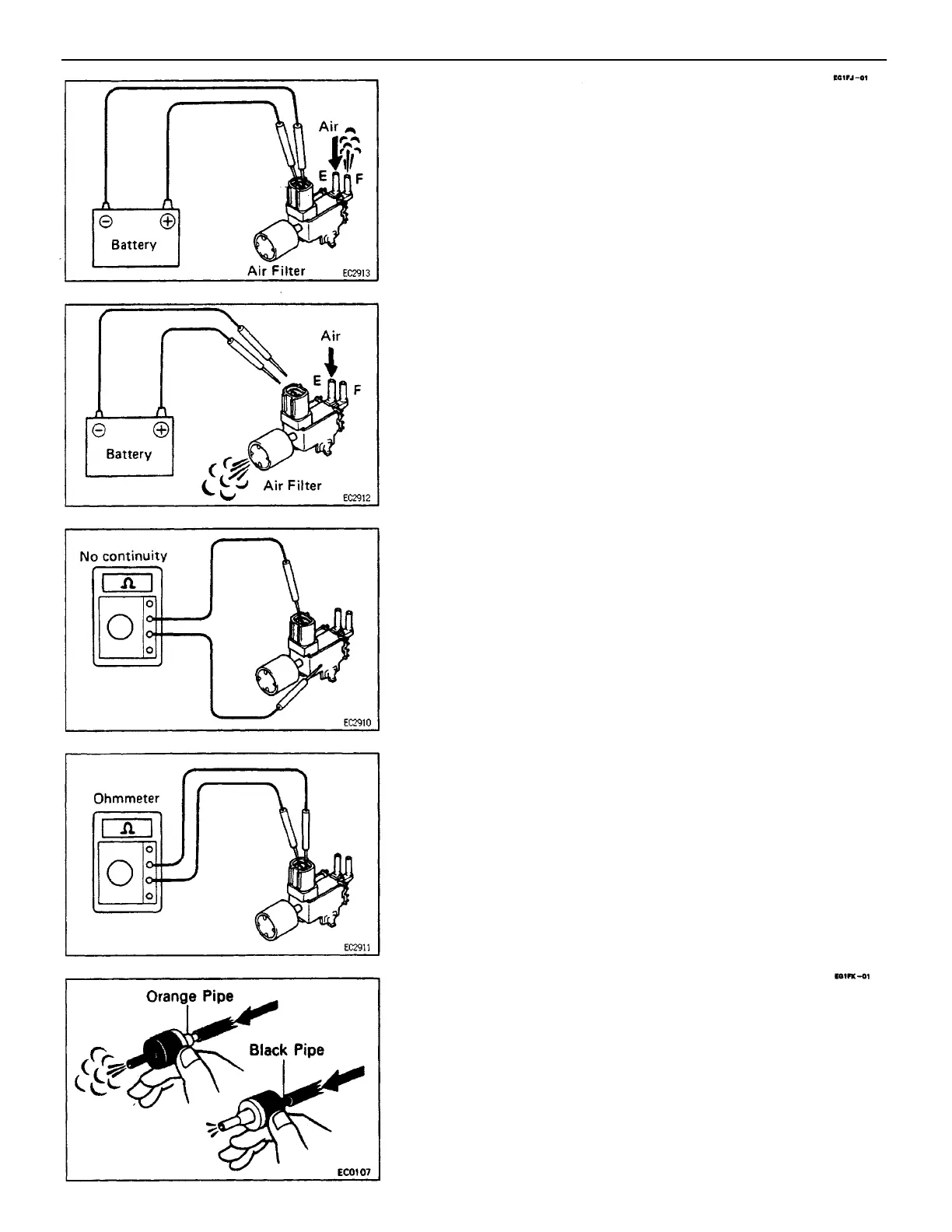

CHECK VALVE INSPECTION

CHECK VALVE BY BLOWING AIR INTO EACH PIPE

(a) Check that air flows from the orange pipe to the black

pipe.

(b) Check that air does not flow fron the black pipe to the

orange pipe.

3. CHECK FOR OPEN CIRCUIT

Using an ohmmeter, measure the resistance between

the terminals.

Specified resistance: 30 – 50 at 20 C (68 F)

If the resistance is not within specification, replace

the VSV.

2. CHECK FOR SHORT CIRCUIT

Using an ohmmeter, check that there is no continuity

between the terminals and the VSV body.

If there is continuity, replace the VSV.

(c) Disconnect the battery.

(d) Blow air into pipe E and check that air comes out of air

filter.

If a problem is found, replace the VSV.

–ENGINE EMISSION CONTROL SYSTEMS

EG2–154

Loading...

Loading...