COMPONENTS INSPECTION

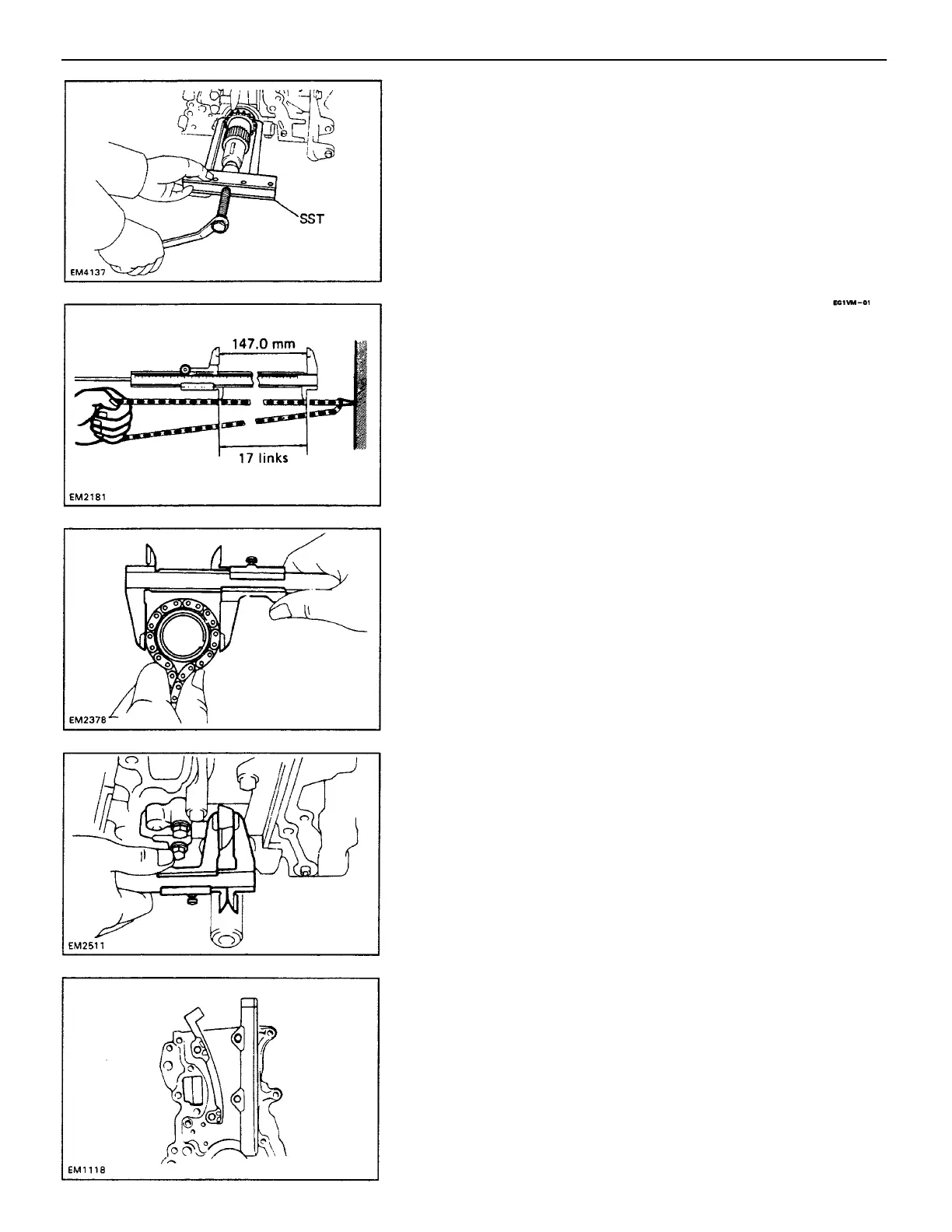

1. MEASURE CHAIN AND SPROCKET WEAR

(a) Measure the length of 17 links with the chain fully

stretched.

(b) Make the same measurements at least three other

places selected at random.

Chain elongation limit at 17 links: 147.0 mm (5.787 in.)

If over the limit at any one place the chain.

(c) Wrap the chain around the sprocket.

(d) Using a caliper gauge, measure the outer sides of the

chain rollers as shown. Measure both sprockets.

Crankshaft sprocket minimum: 59.4 mm (2.339 in.)

Camshaft sprocket minimum: 113.8 mm (4.480 in.)

If the measurement is less than minimum, replace the

chain and two sprockets.

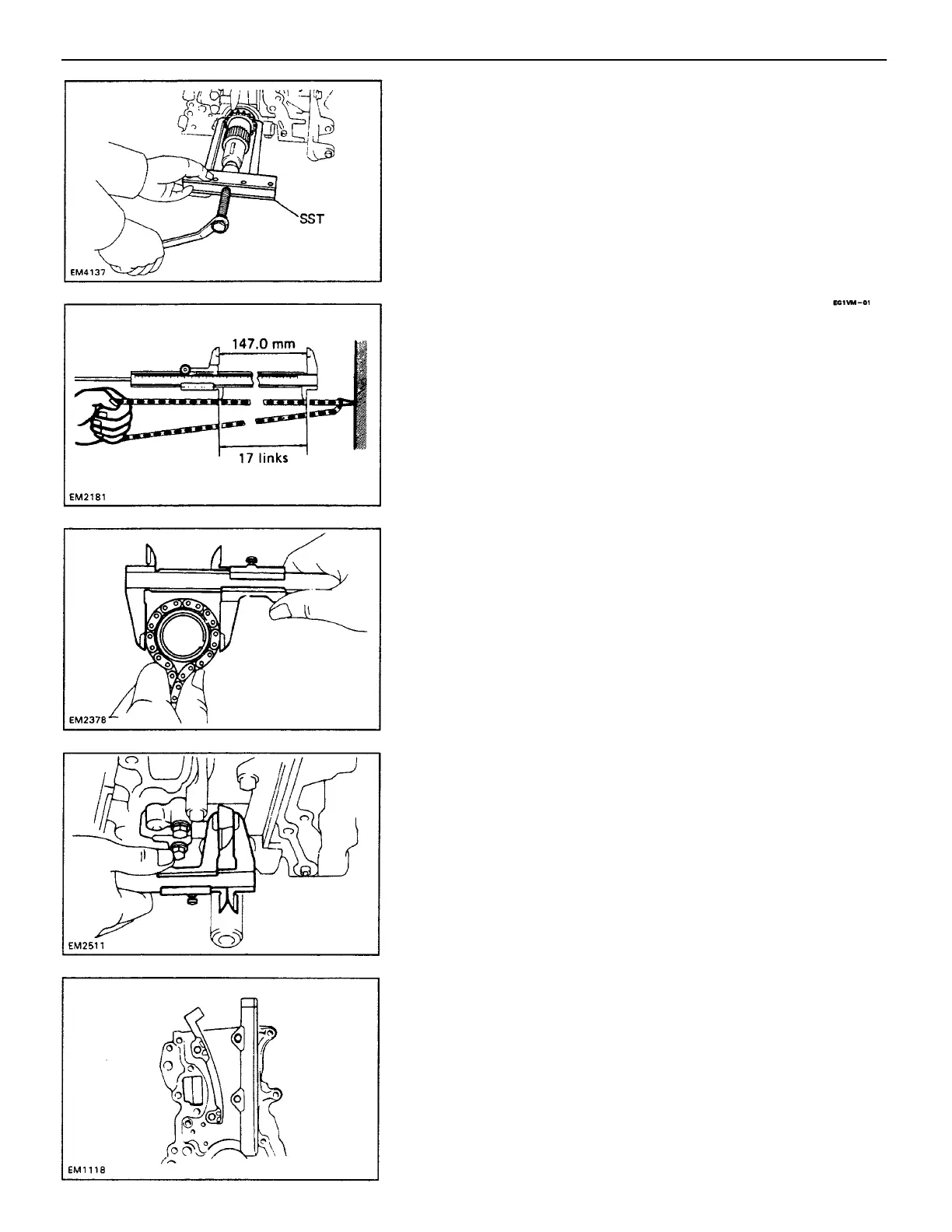

10. REMOVE PUMP DRIVE SPLINE AND CRANKSHAFT

SPROCKET

If the oil pump drive spline and sprocket cannot be

removed by hand, use SST to remove them together.

SST 09213–36020

11. REMOVE GASKET MATERIAL ON CYLINDER

BLOCK

2. MEASURE CHAIN TENSIONER

Using a caliper gauge, measure the tensioner as

shown.

Tensioner minimum: 11.0 mm (0.433 in.)

If the tensioner is worn or less than minimum, replace

the chain tensioner.

3. MEASURE CHAIN DAMPERS

Using a micrometer, measure each damper.

Damper wear limit: 0.5 mm (0.020 in.)

If either damper is worn or less than minimum, replace

the damper.

–ENGINE ENGINE MECHANICAL

EG1–42

Loading...

Loading...