(i) Remove the main bearing caps.

(j) Measure the Plastigage at its widest point.

Standard clearance: 0.025 – 0.055 mm

(0.0010 – 0.0022 in.)

Maximum clearance: 0.08 mm (0.0031 in.)

If the clearance is greater than maximum, replace the

bearings and/or grind the main journals.

Undersized bearing: U/S 0.25

(k) Clean out the pieces of Plastigage from the bearings

and journals.

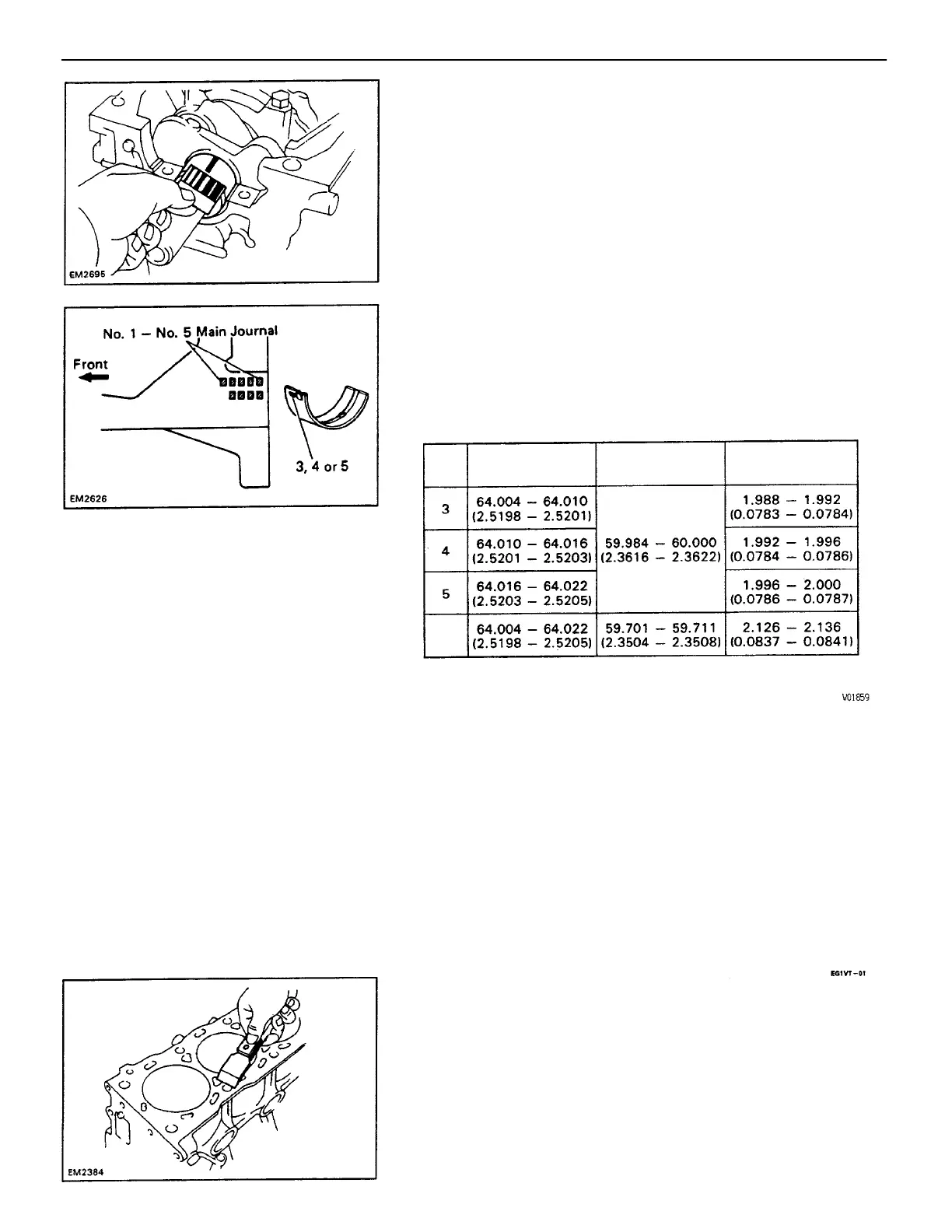

HINT: If using a standard bearing, replace with one

having the same number as marked on the cylinder

block. There are three sizes of standard bearings,

marked 3, 4, 5 accordingly.

CYLINDER BLOCK INSPECTION

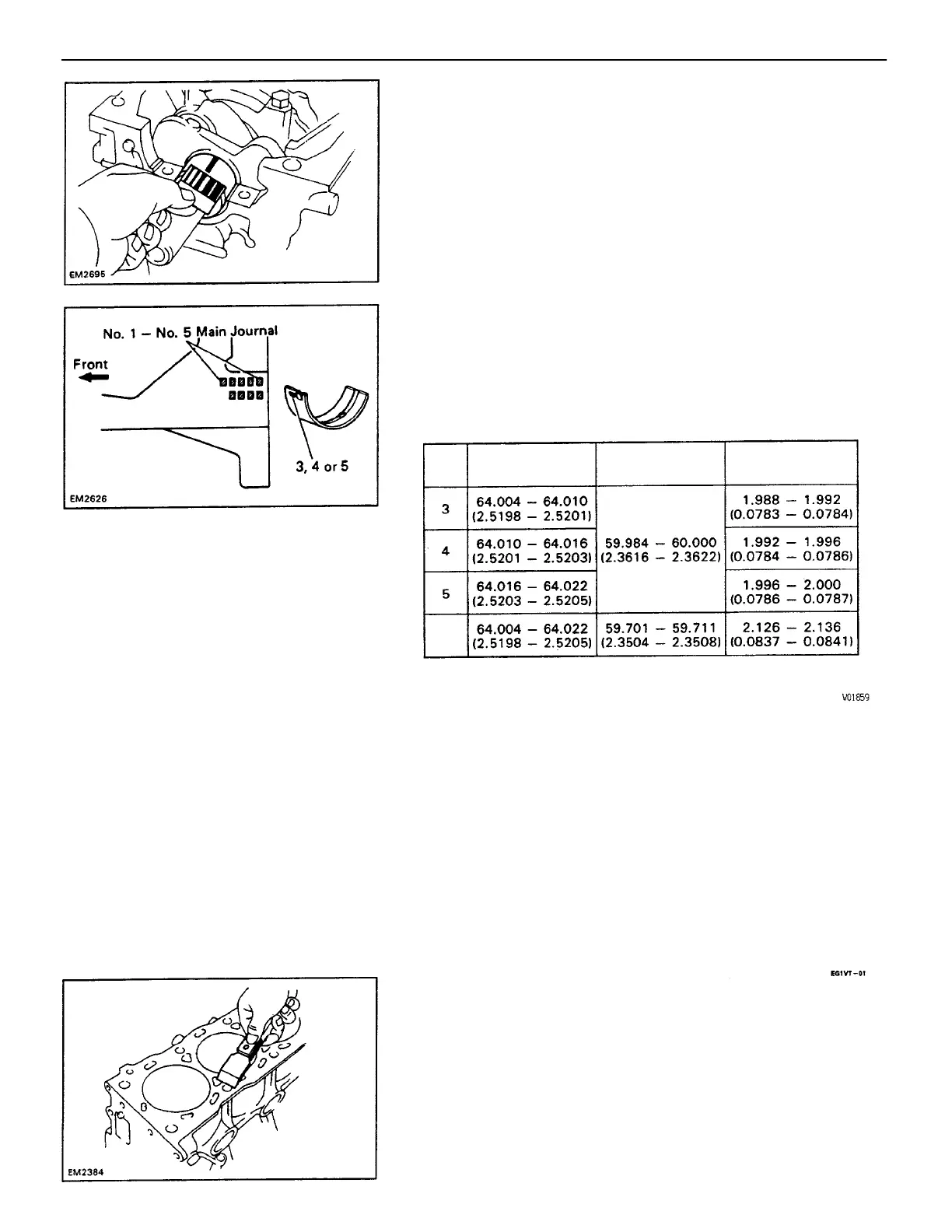

1. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all gasket material

from cylinder block surfaces.

2. CLEAN CYLINDER BLOCK

Using a soft brush and solvent, clean the block.

23. REMOVE CRANKSHAFT ,

(a) Lift out the crankshaft.

(b) Remove the upper main bearings from the cylinder

block.

(c) Arrange the caps and bearings in order.

Cylinder Block

Main Journal Bore

Bearing Center

Wall Thickness

Main Journal

Diameter

mm (in.)

U /S

Q.25

Size

–ENGINE ENGINE MECHANICAL

EG1–55

Loading...

Loading...