Maximum cam lobe height:

Intake 42.25 mm (1.6634 in.)

Exhaust 42.30 mm (1.6654 in.)

If the lobe height is less than ,minimum, replace the

camshaft.

(c) Using a micrometer, measure the journal diameter.

Standard diameter: 32.98 – 33.00 mm

(1.2984 – 1.2992 in.)

If the journal diameter is less than specified, replace

the camshaft.

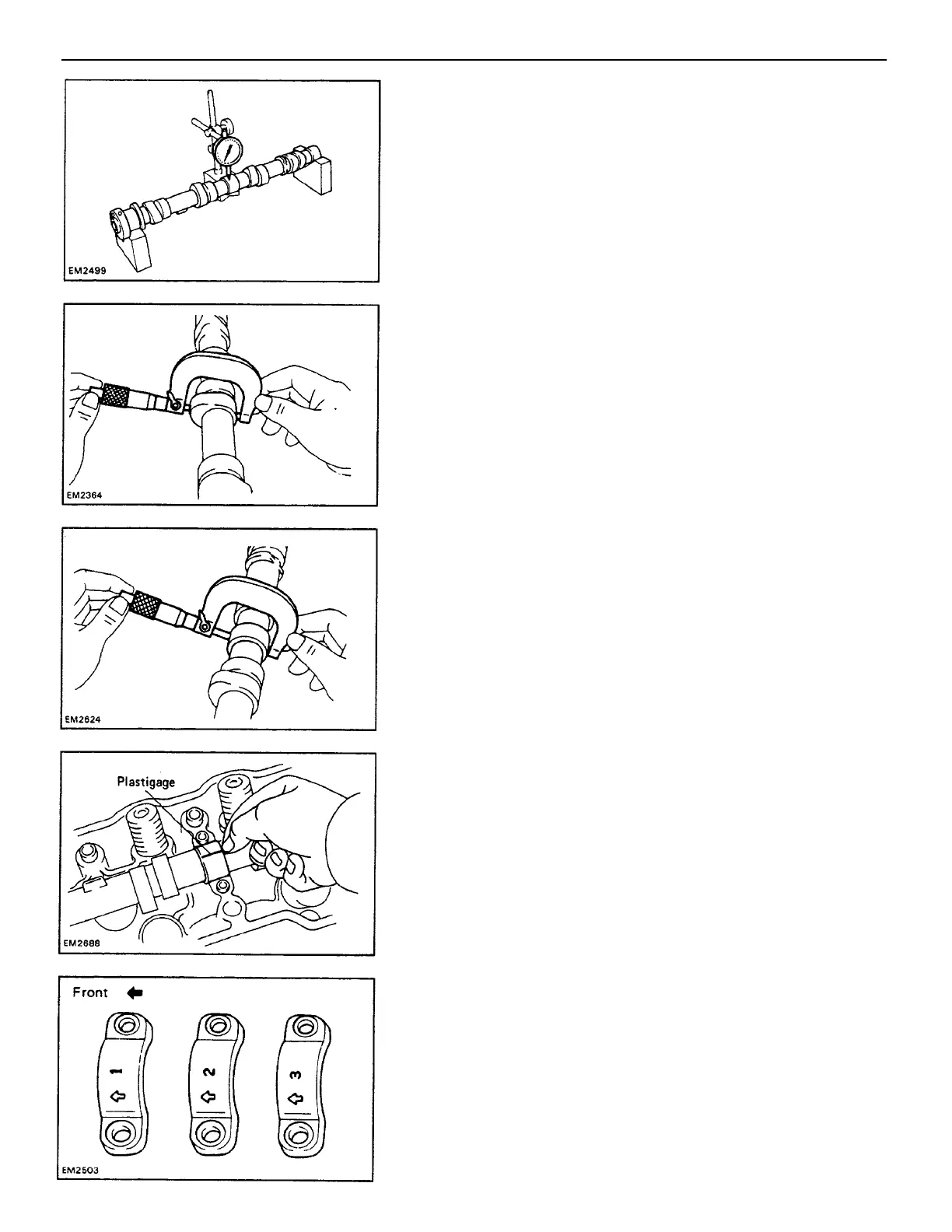

(d) Install the correct numbered bearing cap on each

journal with the arrows pointing toward the front.

Torque each bolt.

Torque: 20 N–m (200kgf.–cm, 14ft–lbf)

HINT: Do not turn the camshaft while the Plastigags is

in place.

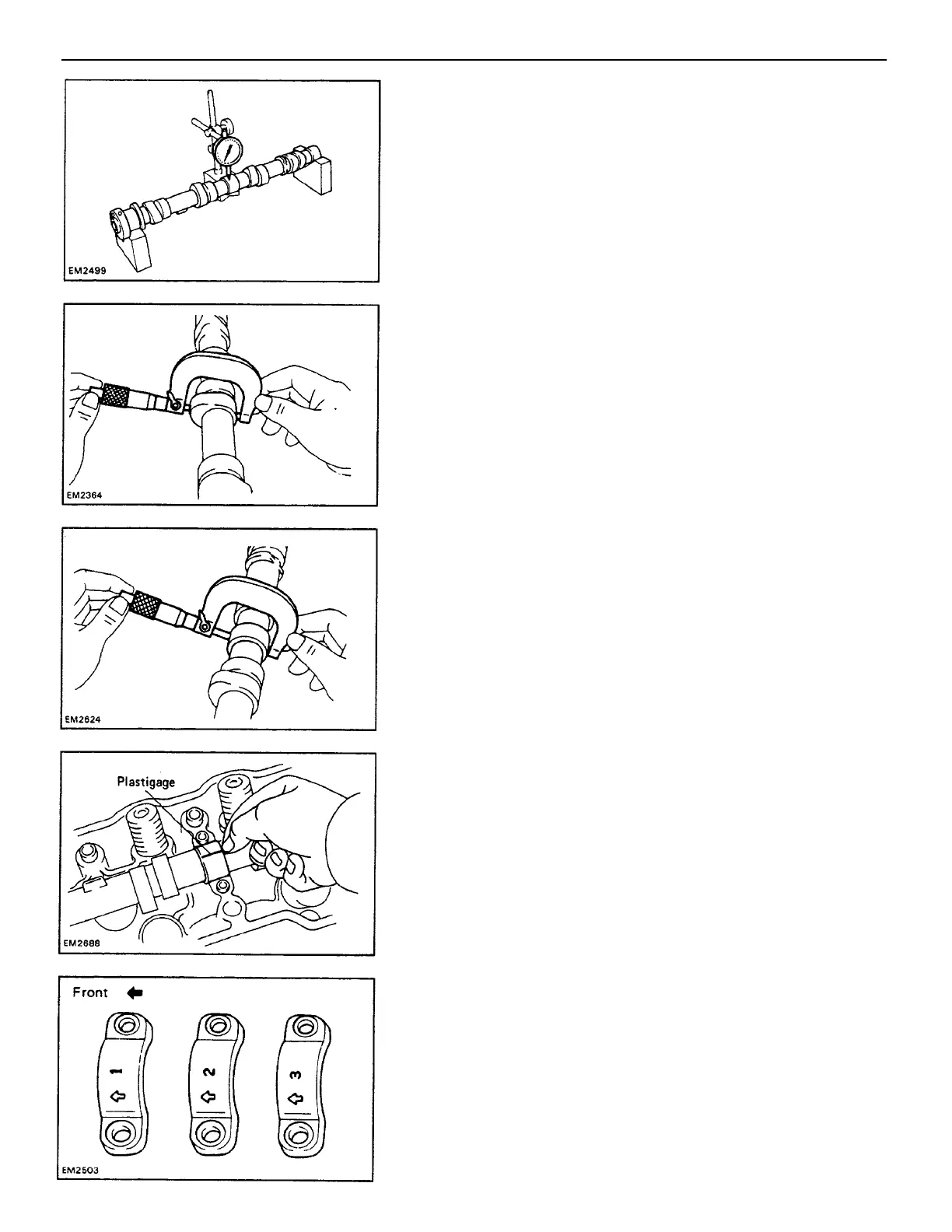

14. INSPECT CAMSHAFT AND BEARING CAPS

(a) Place the cam shaft on V – blocks and , using a dial

indicator, measure the circle runout at the center

journal.

Maximum circle runout: 0.2 mm (0.008 in.)

If the circle runout is greater than maximum, replace

the camshaft.

15. INSPECT CAMSHAFT OIL CLEARANCE

(a) Clean the bearing caps and camshaft journal.

(b) Place the camshaft in the cylinder head.

(c) Lay a strip of Plastigage across each journal.

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake 42.63 – 42.72 mm (1.6783 – 1.6818 in.)

Exhaust 42.69 – 42.78 mm (1.6807 – 1.6842 in.)

–ENGINE ENGINE MECHANICAL

EG1–28

Loading...

Loading...