Draining

1

Before staring work, ensure the motorcycle is

1

stabilised and-adequately supported. This will help

prevent it from falling and causing injury to the

operator or damage to the motorcycle.

1.

Remove the fork (see page 13-4).

2.

Remove the top cap assembly (see page 13-7).

3.

Remove the fork spring (see page 13-7).

4.

Holding the inner and outer tubes together, invert

the fork and pour out the fork oil into a suitable

container. Pump the damper rod to remove all

the oil.

Oil Refilling

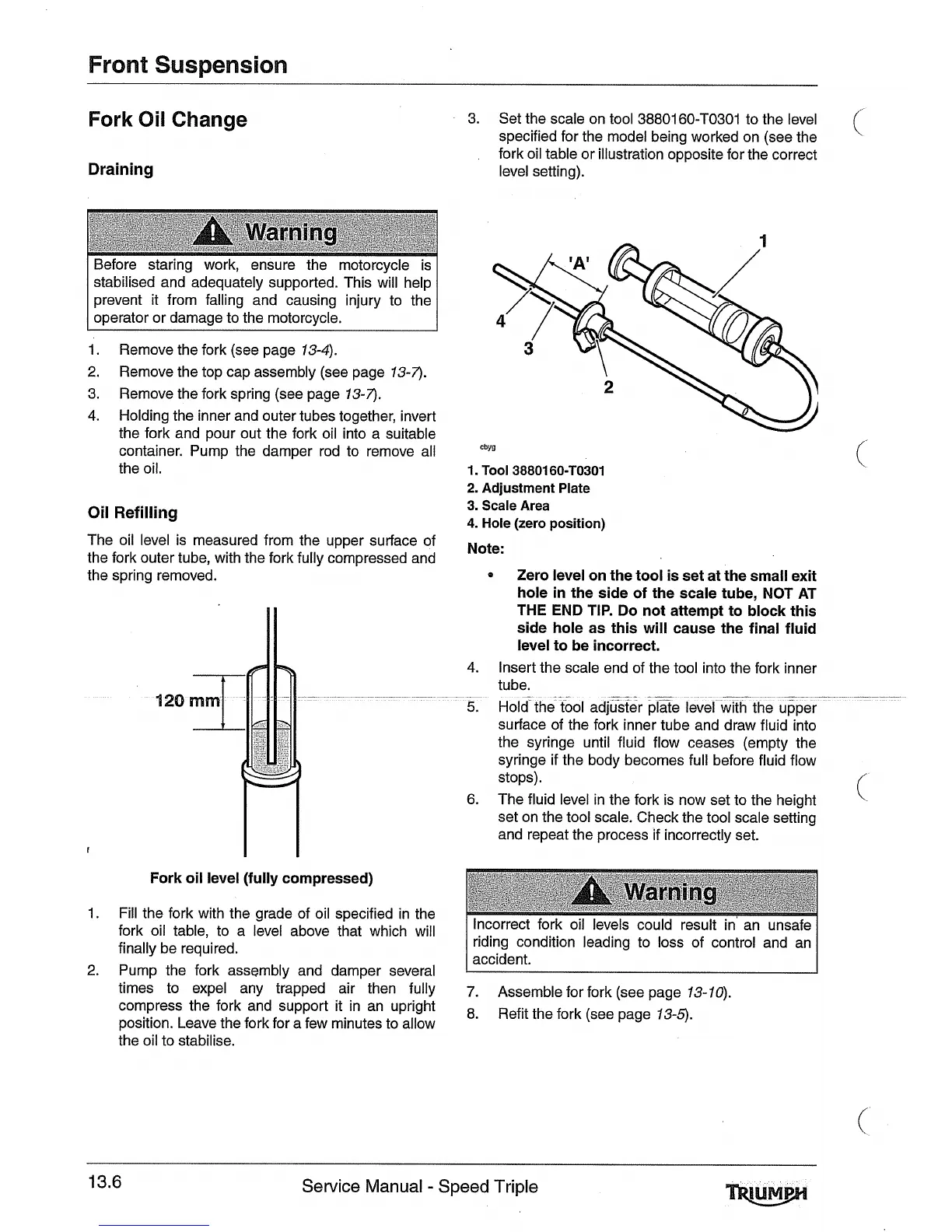

The oil level is measured from the upper surface of

the fork outer tube, with the fork fully compressed and

the spring removed.

Fork oil level (fully compressed)

1.

Fill the fork with the grade of oil specified in the

fork oil table, to a level above that which will

finally be required.

2.

Pump the fork assembly and damper several

times to expel any trapped air then fully

compress the fork and support it in an upright

position. Leave the fork for a few minutes to allow

the oil to stabilise.

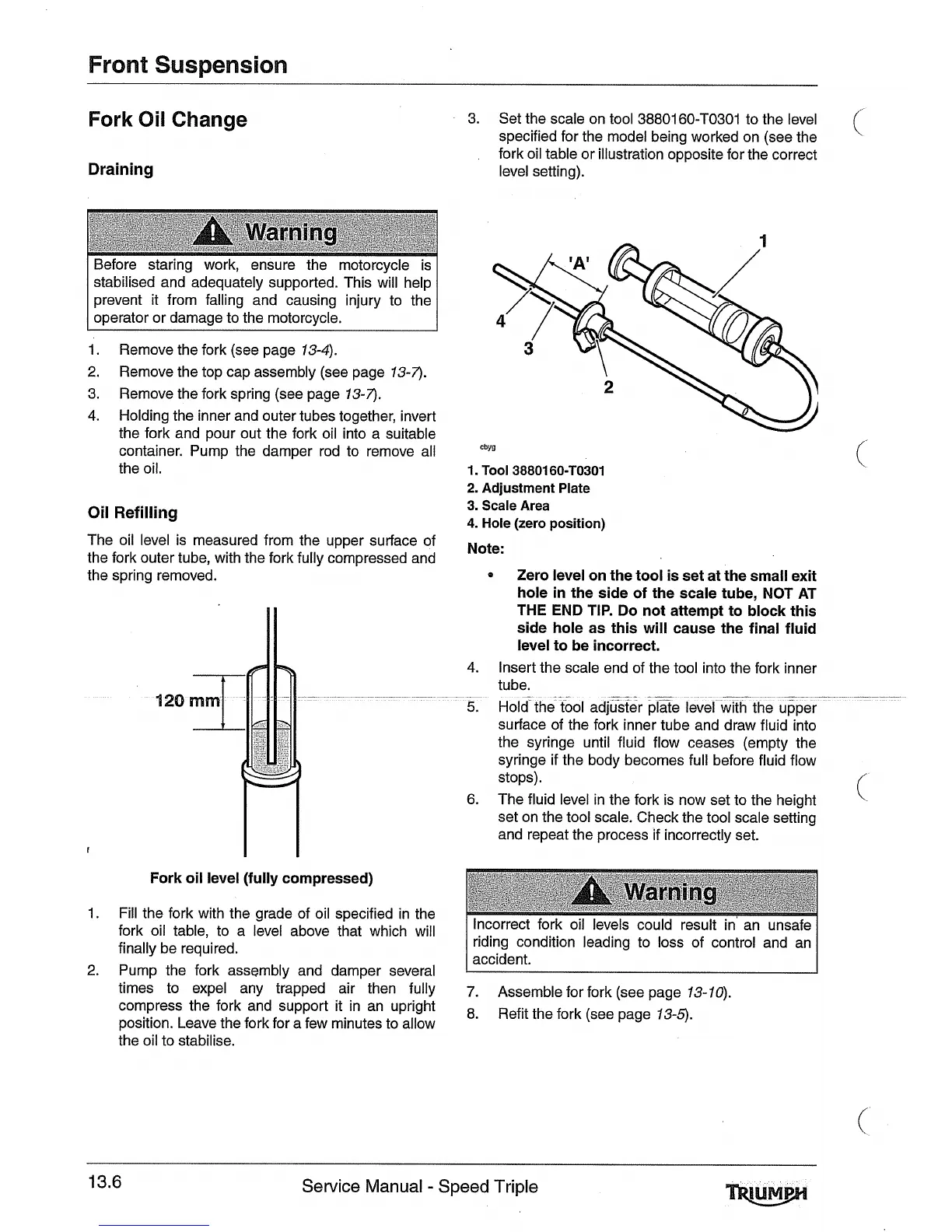

3. Set the scale on tool 3880160-TO301 to the level

specified for the model being worked on (see the

fork oil table or illustration opposite for the correct

level setting).

1. To01 38801 60-TO301

2.

Adjustment Plate

3. Scale Area

4.

Hole (zero position)

Note:

*

Zero level on the tool is set at the small exit

hole in the side of the scale tube, NOT AT

THE END TIP. Do not attempt to block this

side hole as this will cause the final fluid

level to be incorrect.

4.

Insert the scale end of the tool into the fork inner

tube.

surface of the fork inner tube and draw fluid into

the syringe until fluid flow ceases (empty the

syringe if the body becomes full before fluid flow

stops).

6.

The fluid level in the fork is now set to the height

set on the tool scale. Check the tool scale setting

(

and repeat the process if incorrectly set.

Incorrect fork oil levels could result in' an unsafe

riding condition leading to loss of control and an

accident.

7.

Assemble for fork (see page 13-10).

8.

Refit the fork (see page 13-5).

Sewice Manual

-

Speed Triple

Loading...

Loading...