Crankshaft, Connecting Rods and Pistons

4.

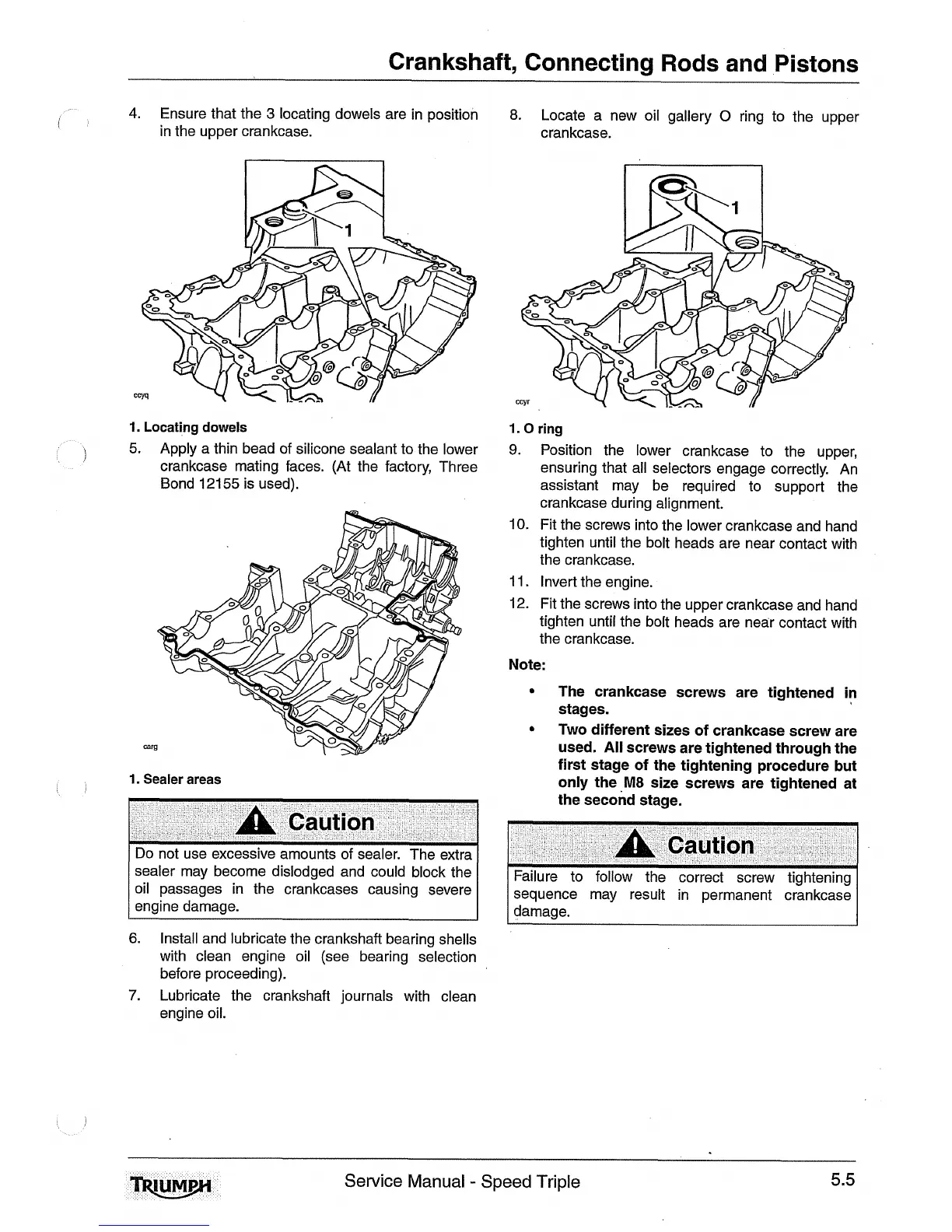

Ensure that the

3

locating dowels are in position

i

in the upper crankcase.

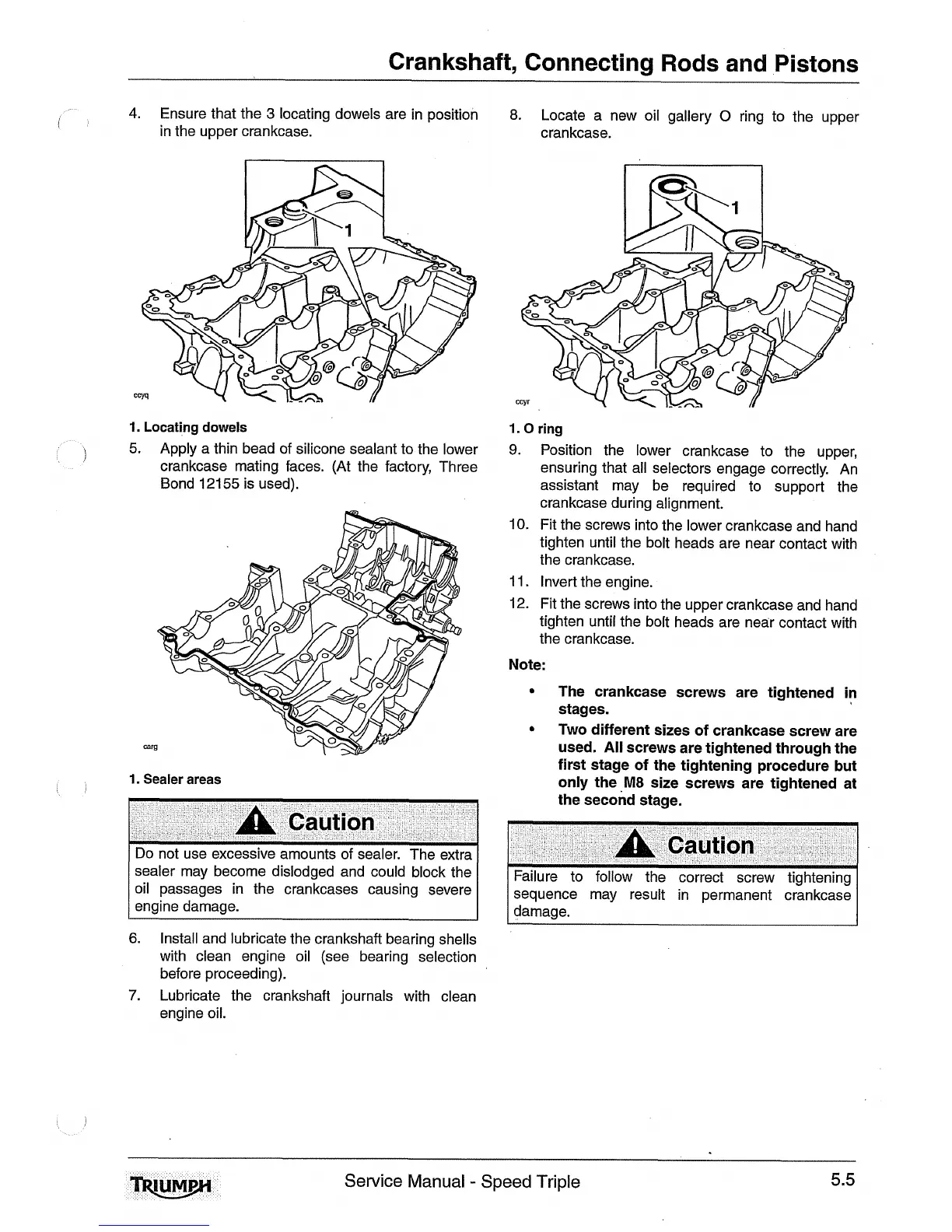

8.

Locate a new oil gallery

0

ring to the upper

crankcase.

1.

Locating dowels

i

5.

Apply a thin bead of silicone sealant to the lower

crankcase mating faces. (At the factory, Three

Bond 121

55

is used).

1.

Sealer areas

i

A

Caution

I

Do not use excessive amounts of sealer. The extra

I

sealer may become dislodged and could block the

oil passages in the crankcases causing severe

engine damage.

6.

Install and lubricate the crankshaft bearing shells

with clean engine oil (see bearing selection

before proceeding).

7.

Lubricate the crankshaft journals with clean

engine oil.

1.0

ring

9.

Position the lower crankcase to the upper,

ensuring that all selectors engage correctly. An

assistant may be required to support the

crankcase during alignment.

10. Fit the screws into the lower crankcase and hand

tighten until the bolt heads are near contact with

the crankcase.

11. Invert the engine.

12. Fit the screws into the upper crankcase and hand

tighten until the bolt heads are near contact with

the crankcase.

Note:

The crankcase screws are tightened in

stages.

*

Two different sizes of crankcase screw are

used.

All

screws are tightened through the

first stage of the tightening procedure but

only the

M8

size screws are tightened at

the second stage.

A

Caution

1

Failure to follow the correct screw tightening

1

sequence may result in permanent crankcase

I

damage.

Service Manual

-

Speed Triple

5.5

Loading...

Loading...