110 Start-up

Performing test moves - relative positional move

This section tests the basic operation of the drive and motor by performing a

positional move. To stop a move in progress, click the red stop button or the drive

enable button on the toolbar. Alternatively, use the Mint WorkBench ‘Red Stop Button’

feature.

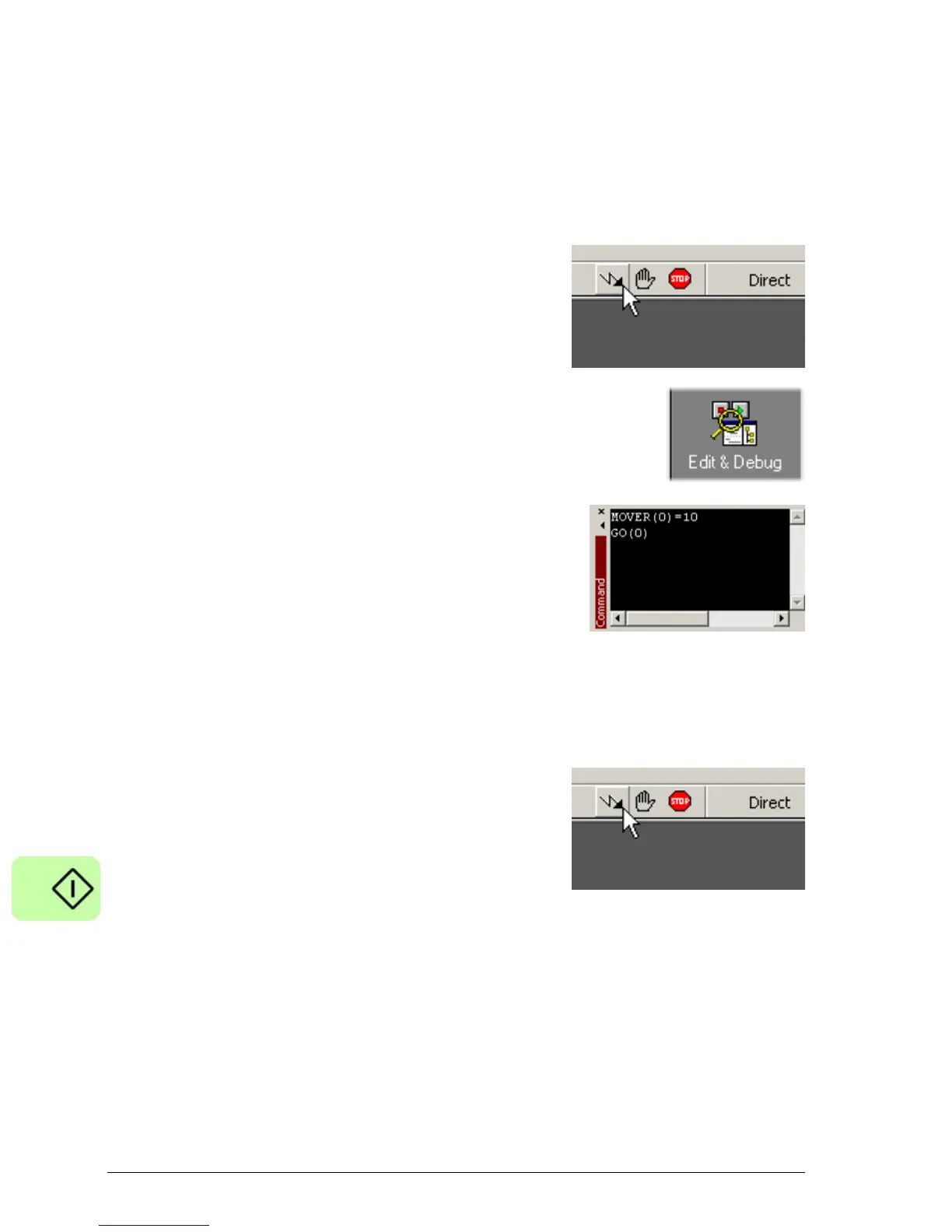

1. Check that the Drive enable button is

pressed (down).

2. In the Toolbox, click the Edit & Debug

icon.

3. Click in the Command window.

Type:

MOVER(0)=10

GO(0)=10

This will cause the motor to move to a

position 10 units from its current position.

The move will stop when completed.

4. If you have finished testing click the

Drive Enable button to disable the

drive.

Loading...

Loading...