Chapter 2 InstallationASDA-A2R Series

Revision December, 2014

2-5

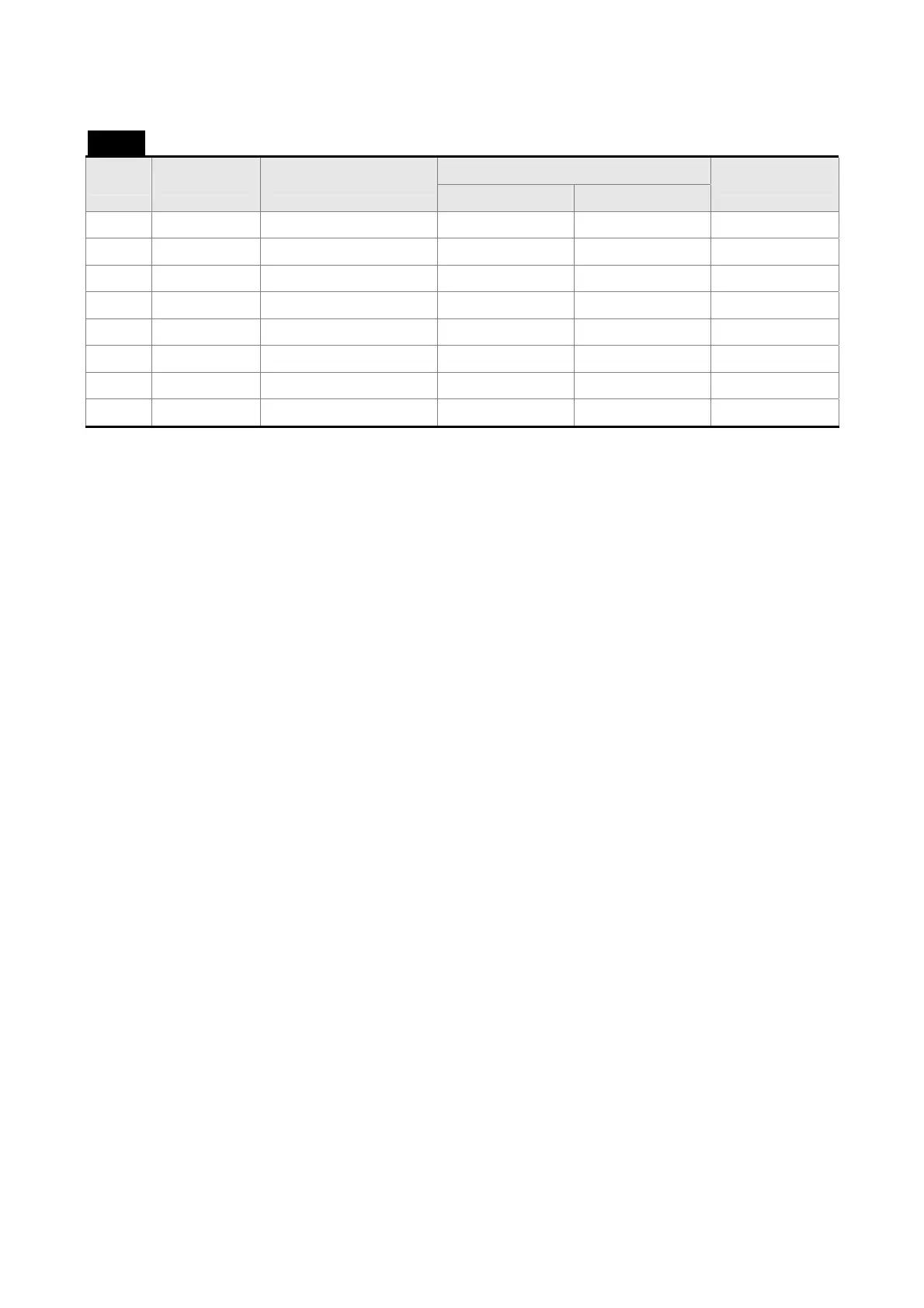

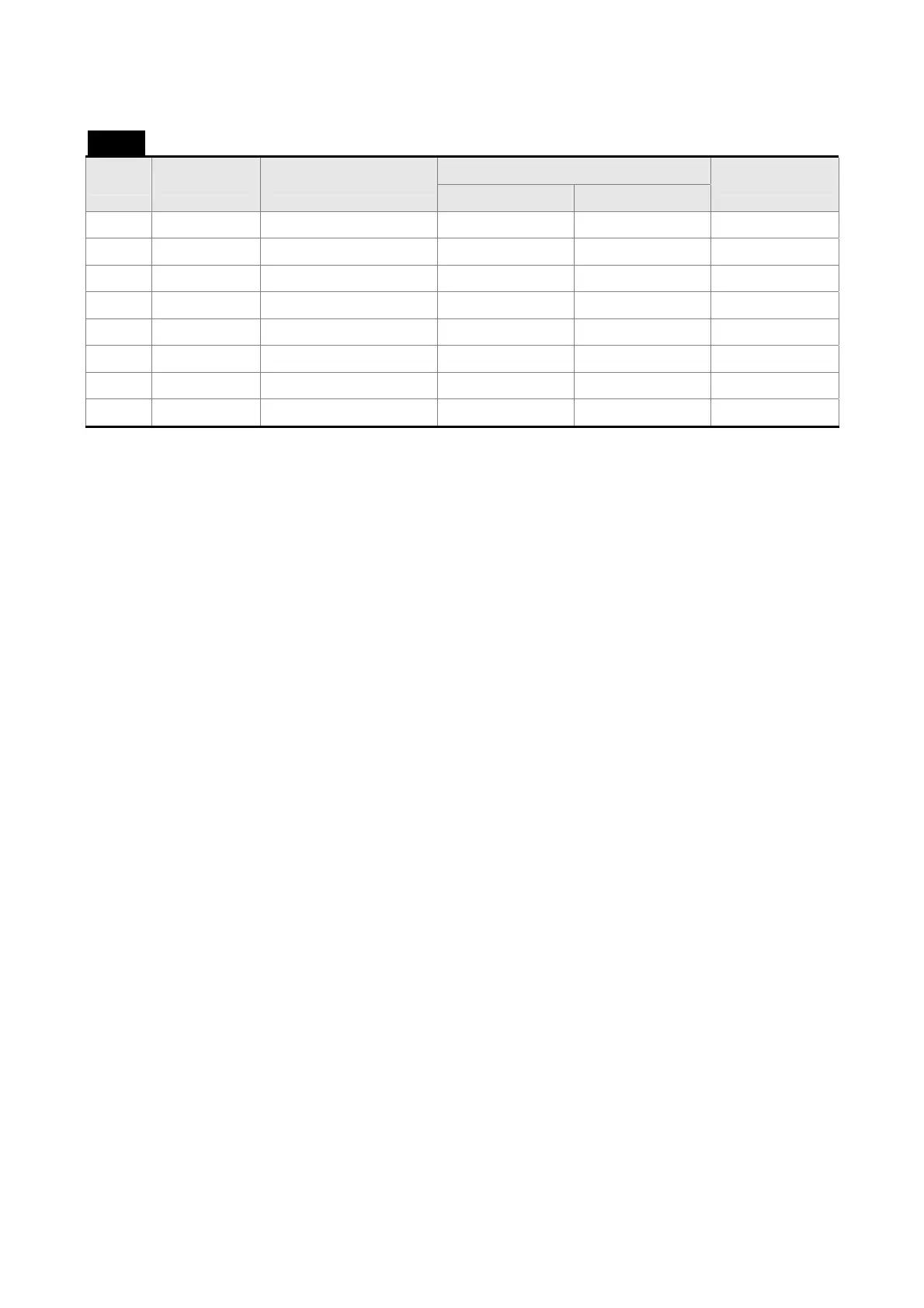

2.6 EMI Filters Selection

220 V

Item Power Servo Drive Model

EMI Filter Model

FootPrint

1PH 3PH

1 100 W ASD-A2R-0121- RF007S21AA RF022B43AA N

2 200 W ASD-A2R-0221- RF007S21AA RF022B43AA N

3 400 W ASD-A2R-0421- RF007S21AA RF022B43AA N

4 750 W ASD-A2R-0721- RF007S21AA RF037B43BA N

5 1000 W ASD-A2R-1021- RF007S21AA RF037B43BA N

6 1500 W ASD-A2R-1521- RF015B21AA RF037B43BA N

7 2000 W ASD-A2R-2023- - RF037B43BA N

8 3000 W ASD-A2R-3023- - RF037B43BA N

EMI Filter Installation

All electronic equipment (including servo drive) generates high or low frequency noise

during operation and interfere the peripheral equipments via conduction or radiation. With

EMI Filter and the correct installation, much interference can be eliminated. It is suggested

to use Delta’s EMI Filter to suppress the interference better.

When installing servo drive and EMI Filter, please follow the instructions of the user manual

and make sure it meets the following specification.

1. EN61000-6-4 (2001)

2. EN61800-3 (2004) PDS of category C2

3. EN55011+A2 (2007) Class A Group 1

General Precaution

In order to ensure the best performance of EMI Filter, apart from the instructions of servo

drive installation and wiring, please follow the precautions mention below:

1. The servo drive and EMI Filter should be installed on the same metal plate.

2. When installing servo drive and EMI Filter, the servo drive should be installed above

the EMI Filter.

3. The wiring should be as short as possible.

4. The metal plate should be well grounded.

5. The metal cover of the servo drive and EMI Filter or grounding should be firmly fixed

on the metal plate. Also, the contact area should be as large as possible.

Loading...

Loading...