USING THE IPMI TOOL SET

EATON Managed ePDUt User’s Guide S 164201xxx Rev 1 DRAFT 10−OCT−2008

100

thresh <id> <threshold> <setting>

Purpose:

Sets a particular sensor threshold value. The sensor is specified by name. Valid

thresholds are:

S unr Upper Non−Recoverable

S ucr Upper Critical

S unc Upper Non−Critical

S lnc Lower Non−Critical

S lcr Lower Critical

S lnr Lower Non−Recoverable

Example:

$ ipmitool −I lan −H test−pdupcr20−20 −U admin −P pass sensor

get “R.14 Current” unr 10.5

OEM Commands

You can use the OEM commands to manage and control the operation of the ePDU.

OEM Net−fn is as defined below:

#define IPMI_NETFN_OEM_PP0x3C

Table 9 lists each OEM command and gives its ID. The sections that follow explain

each command in greater detail.

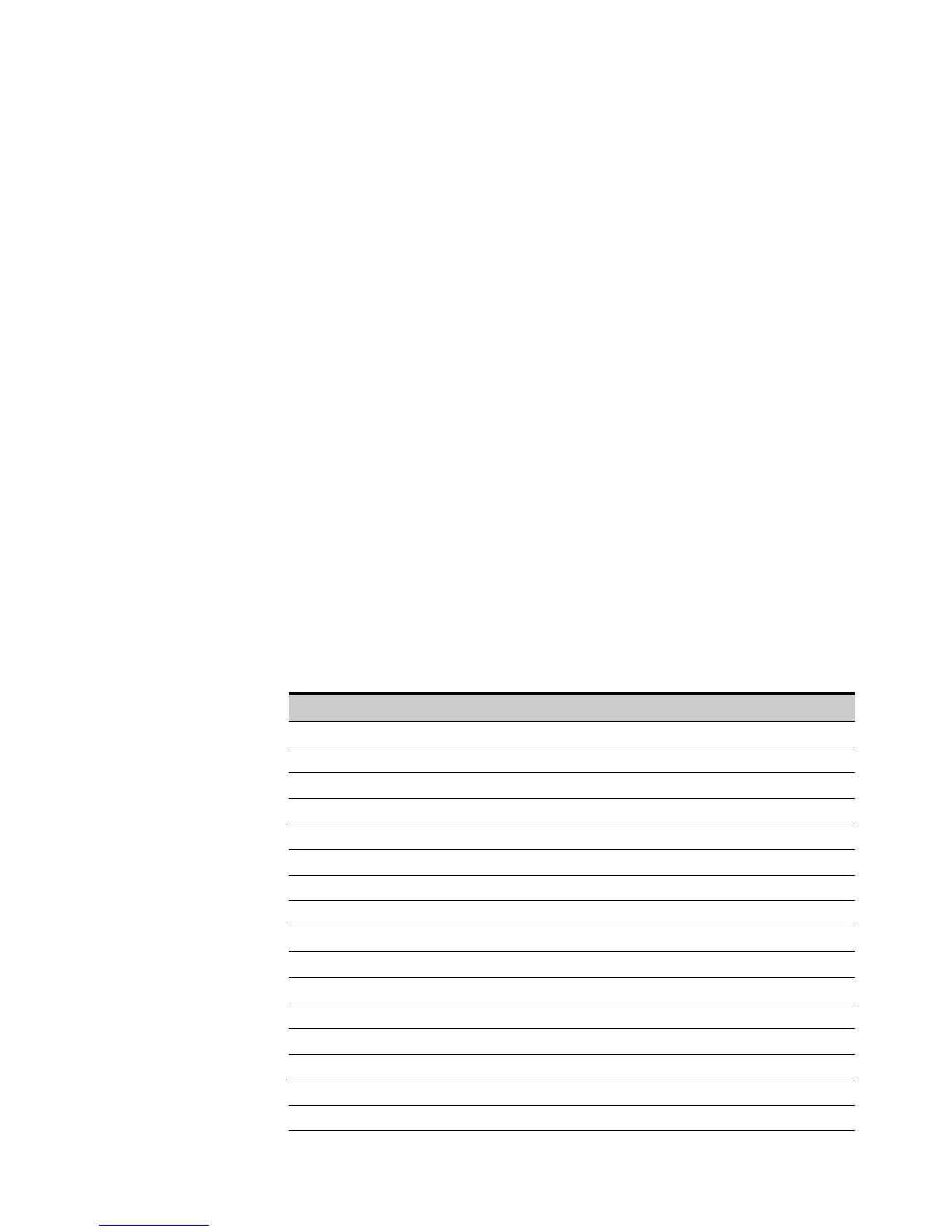

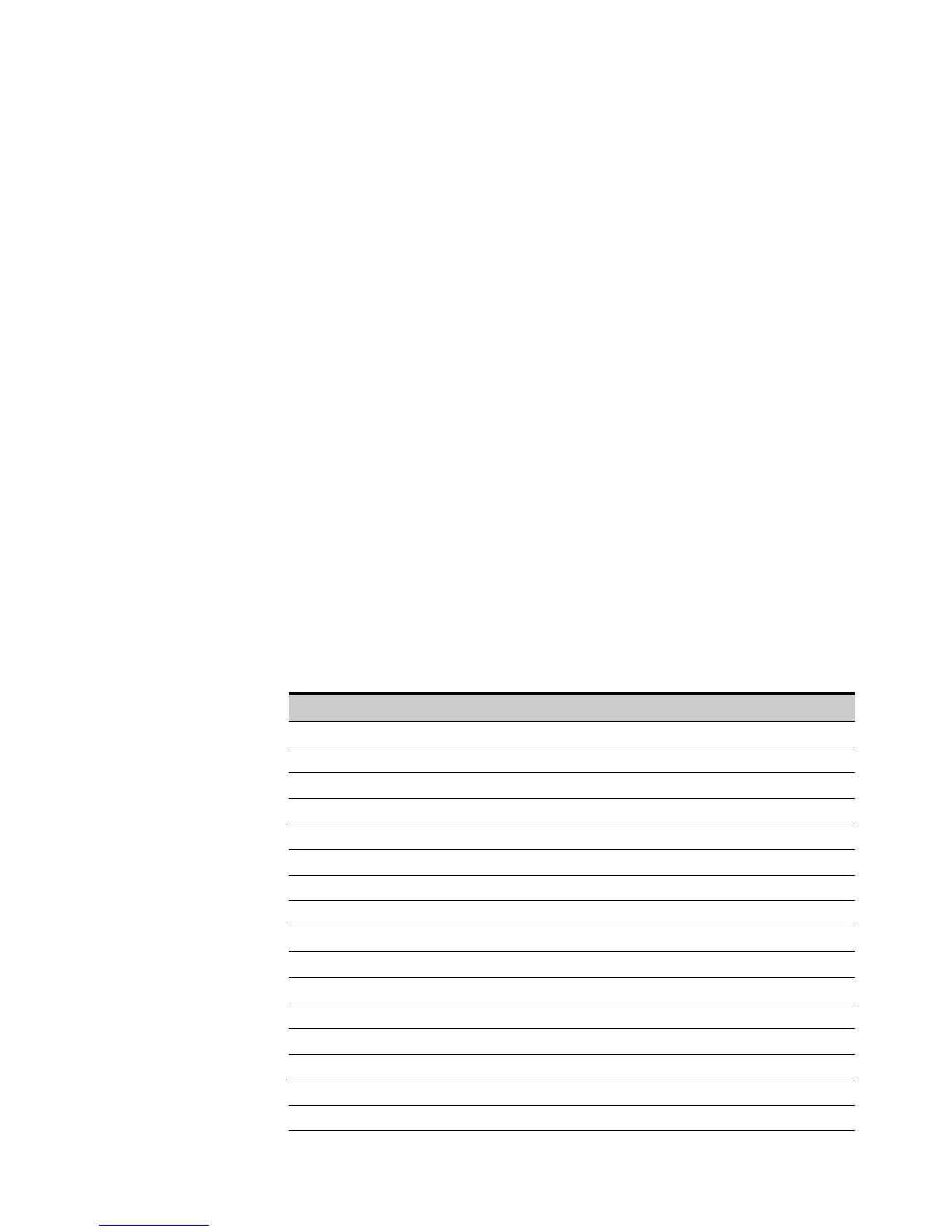

Table 9. OEM Command IDs

Command Name ID

Set Power On Delay 0x10

Get Power On Delay 0x11

Set Socket State 0x12

Get Socket State 0x13

Set Group State 0x14

Set Group Membership 0x15

Get Group Membership 0x16

Set Group Power On Delay 0x17

Get Group Power On Delay 0x18

Set Socket ACL 0x19

Get Socket ACL 0x1A

Set Sensor Calibration 0x1B

Test Actors 0x1C

Test Sensors 0x1D

Set Power Cycle Delay 0x1E

Get Power Cycle Delay 0x1F

Loading...

Loading...