Maintenance 2. General Maintenance

VT Rev.1 117

2.1.2 Inspection Point

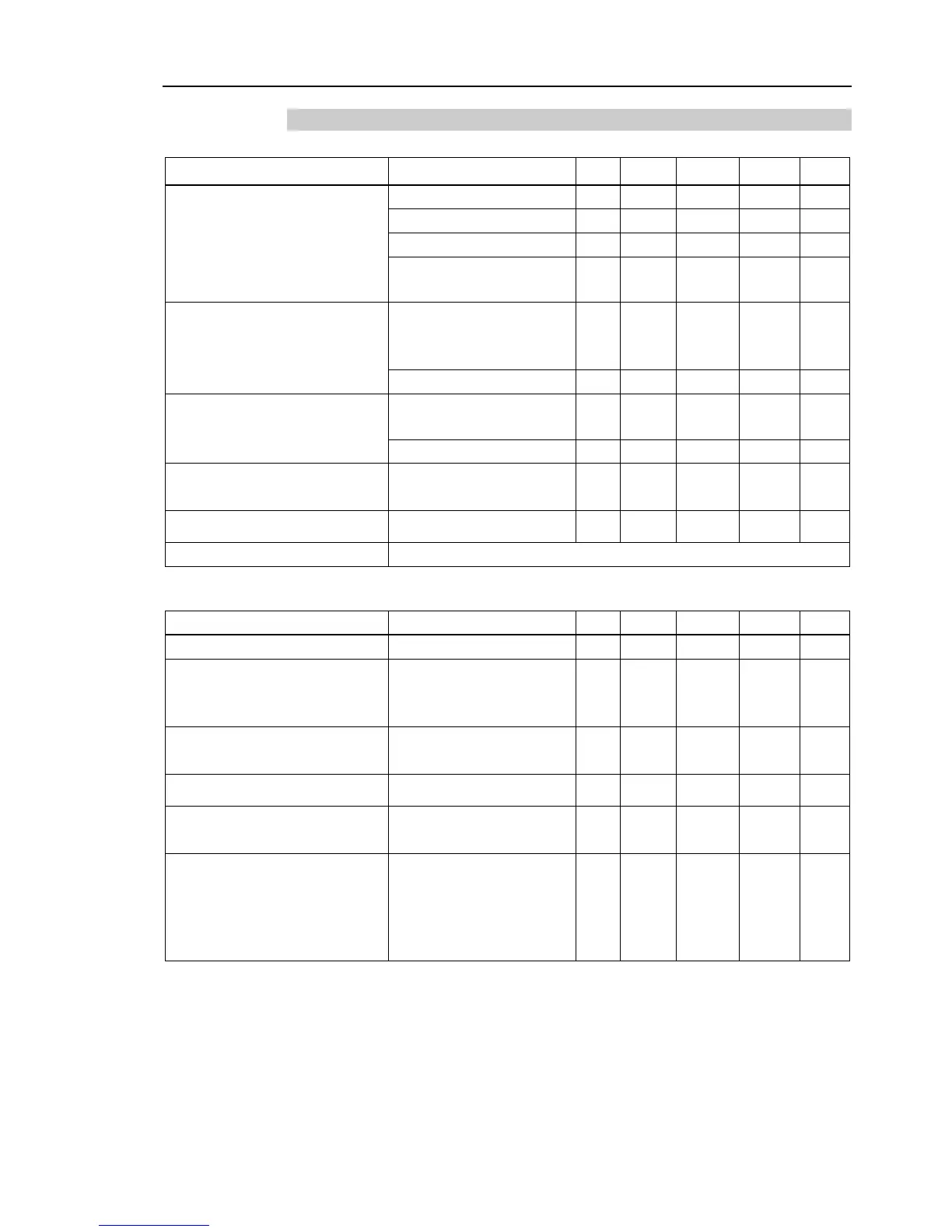

Inspection While the Power is OFF (Manipulator is not operating)

Inspection Point Inspection Place Daily Monthly Quarterly Biannual

Check looseness or backlash of

bolts, screws.

Tighten them if necessary.

(For the tightening torque, refer to

Maintenance: 2.3 Tightening

Hexagon Socket Head Cap Bolts.)

End effector mounting bolts

Manipulator mounting bolts

Bolts, screws securing motors

,

reduction gear units, etc.

√

Check looseness of connectors.

If the connectors are loosen, push it

securely or tighten.

External connectors on

Manipulator (on the connector

Visually check for external defects.

Clean up if necessary.

External appearance of

Check for bends or improper

location. Repair or place it properly

Check tension of timing belts.

Tighten it if necessary.

Inside of Arm #2 √ √

Lithium Battery

Refer to Maintenance: 18.4 Replacing Lithium Battery

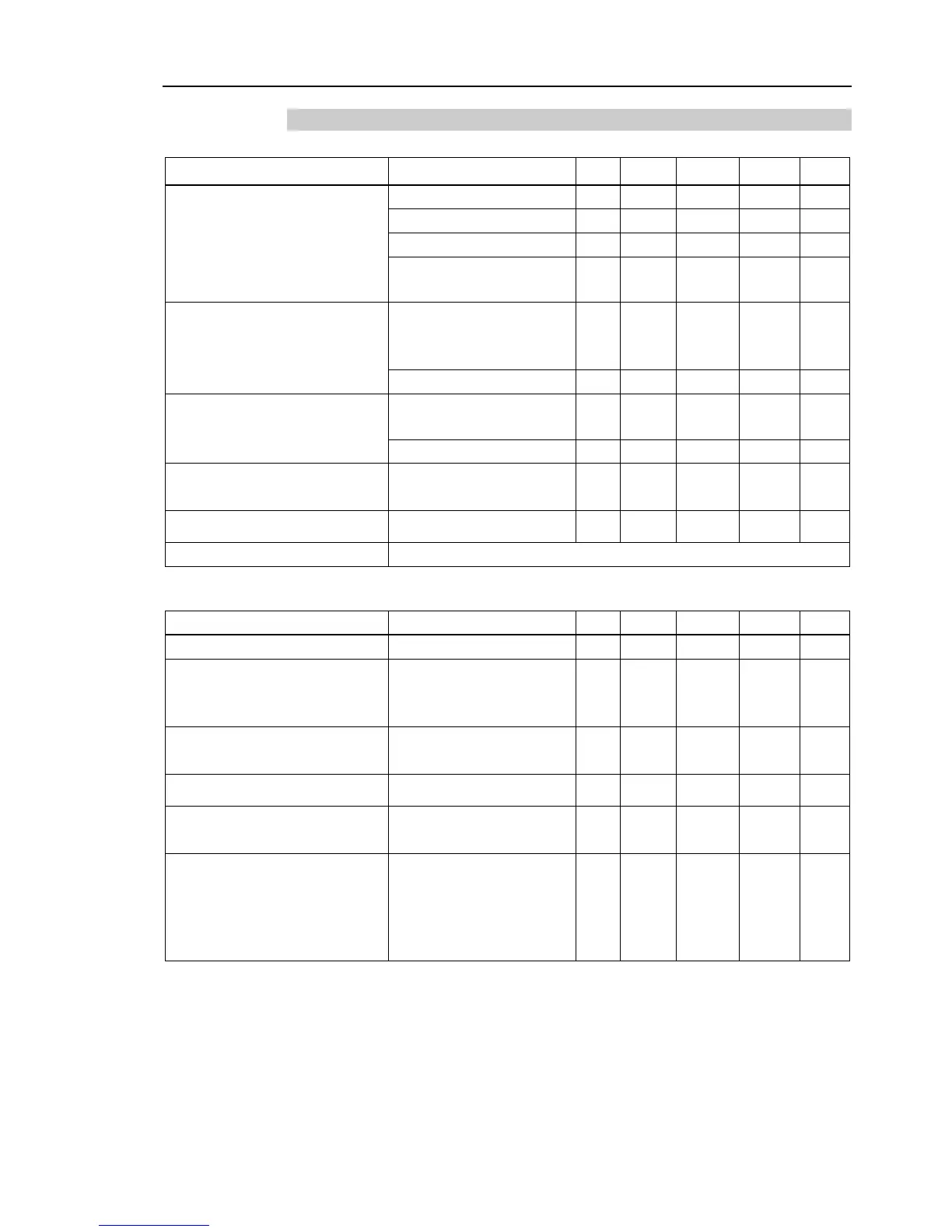

Inspection While the Power is ON (Manipulator is operating)

Move the cables back and forth

lightly to check whether the cables

are disconnected.

External cables

(including cable unit of the

Push each arm in MOTOR ON

status to check whether backlash

Check whether unusual sound or

vibration occurs.

Measure the accuracy repeatedly by

a dial gauge when positional gap

Execute Brake off command (brake

off, joint #) from the command

window of the EPSON RC+ while the

motors are OFF, and then check the

sound of the electromagnetic brake.

If there is no sound, replace the

Loading...

Loading...