01-9

Engine Service

01-9

SERVICE PROCEDURES (Continued)

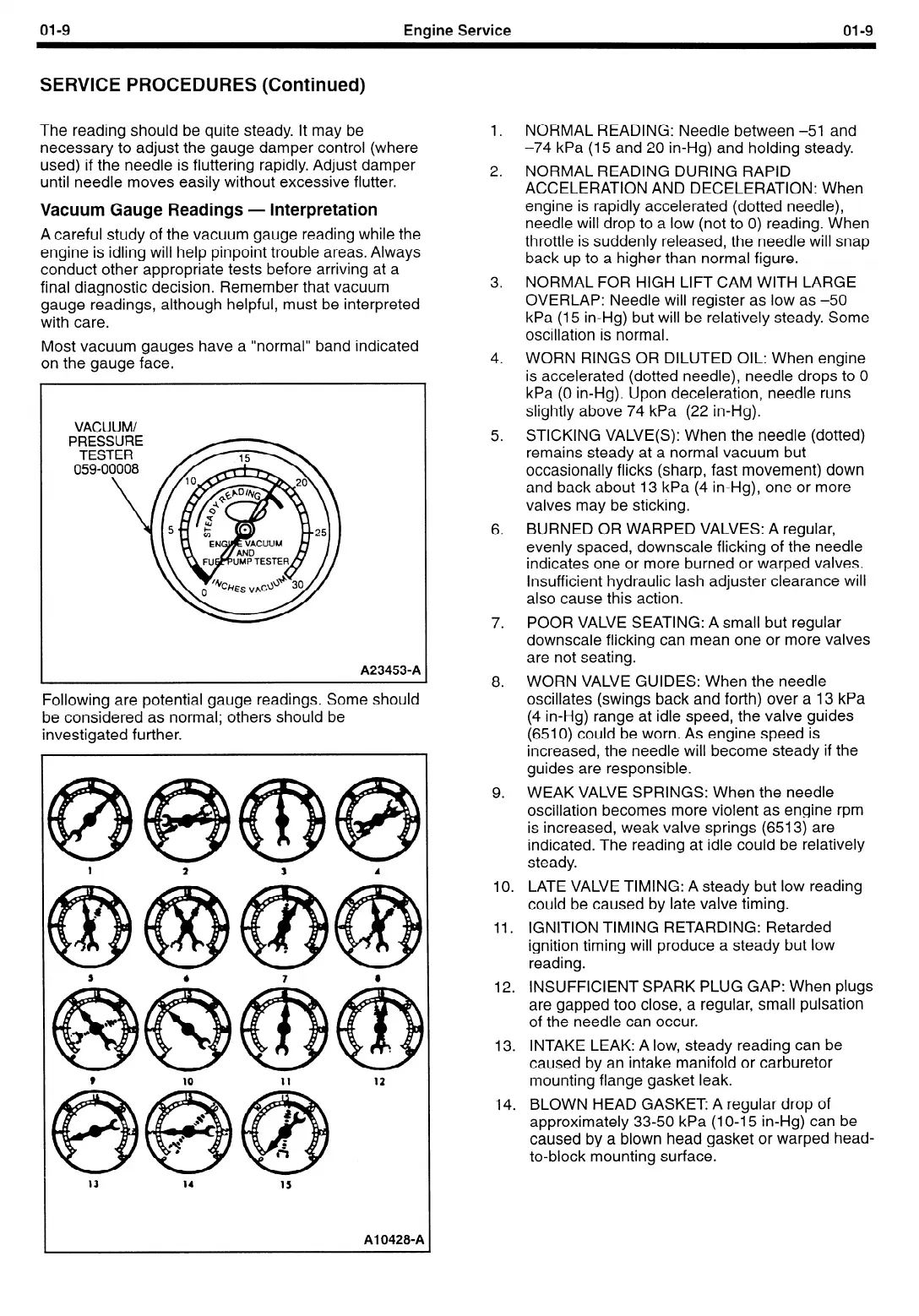

The reading should be quite steady. It may be

necessary to adjust the gauge damper control (where

used) if the needle is fluttering rapidly. Adjust damper

until needle moves easily without excessive flutter.

Vacuum Gauge Readings - Interpretation

A careful study of the vacuum gauge reading while the

engine is idling will help pinpoint trouble areas. Always

conduct other appropriate tests before arriving at a

final diagnostic decision. Remember that vacuum

gauge readings, although helpful, must be interpreted

with care.

Most vacuum gauges have a “normal” band indicated

on the aauae face.

VACUUM/

PRE

TE

059

A23453-A

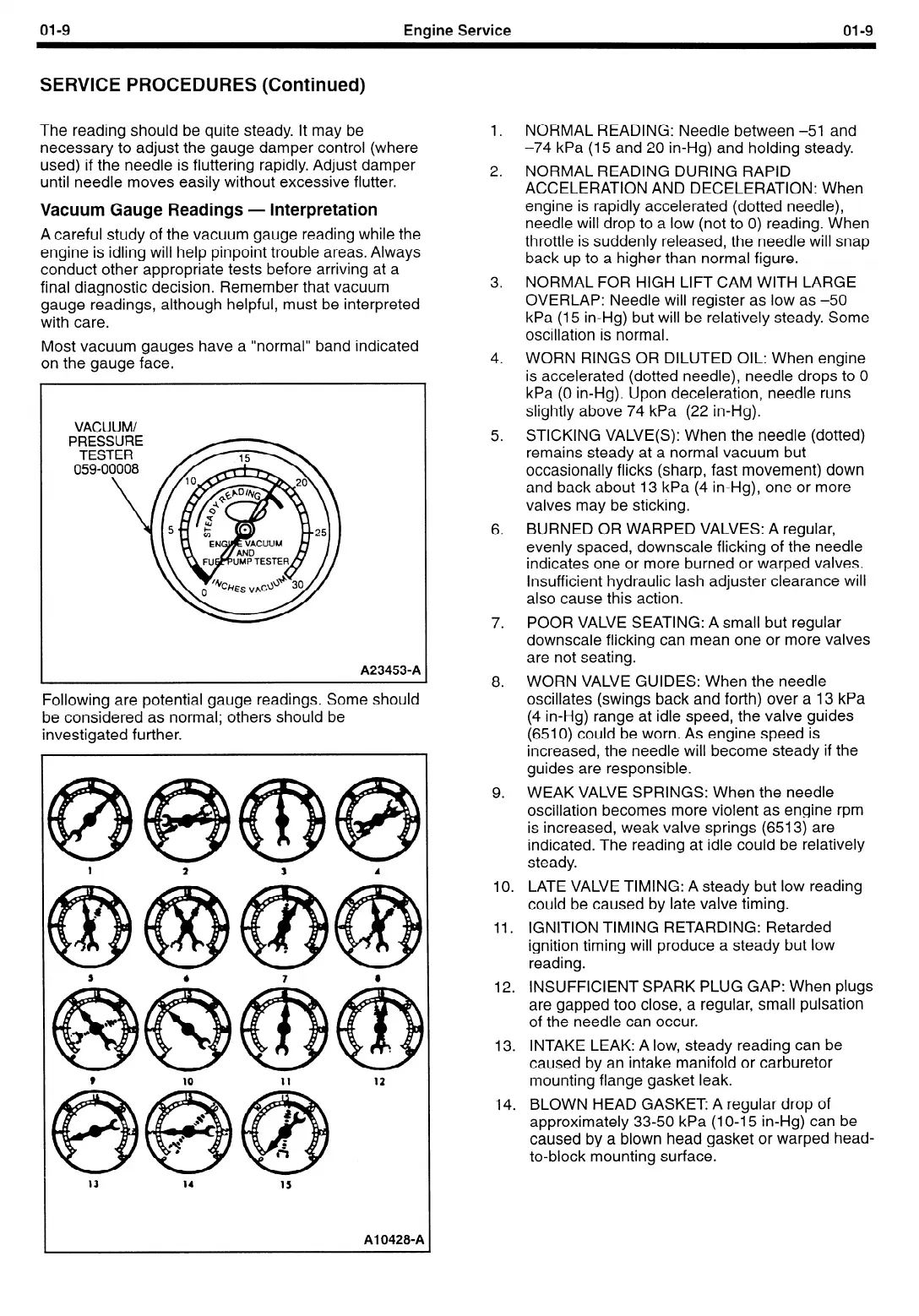

Following are potential gauge readings. Some should

be considered as normal; others should be

investigated further.

Al 0428-P

1.

2.

3.

4.

5.

6.

7.

8.

9.

NORMAL READING: Needle between -51 and

-74 kPa (15 and 20 in-Hg) and holding steady.

NORMAL READING DURING RAPID

ACCELERATION AND DECELERATION: When

engine is rapidly accelerated (dotted needle),

needle will drop to a low (not to 0) reading. When

throttle is suddenly released, the needle will snap

back up to a higher than normal figure.

NORMAL FOR HIGH LIFT CAM WITH LARGE

OVERLAP: Needle will register as low as -50

kPa (15 in-Hg) but will be relatively steady. Some

oscillation is normal.

WORN RINGS OR DILUTED OIL: When engine

is accelerated (dotted needle), needle drops to 0

kPa (0 in-Hg). Upon deceleration, needle runs

slightly above 74 kPa (22 in-Hg).

STICKING VALVE(S): When the needle (dotted)

remains steady at a normal vacuum but

occasionally flicks (sharp, fast movement) down

and back about 13 kPa (4 in-Hg), one or more

valves may be sticking.

BURNED OR WARPED VALVES: A regular,

evenly spaced, downscale flicking of the needle

indicates one or more burned or warped valves.

lnsuff icient hydraulic lash adjuster clearance will

also cause this action.

POOR VALVE SEATING: A small but regular

downscale flicking can mean one or more valves

are not seating.

WORN VALVE GUIDES: When the needle

oscillates (swings back and forth) over a 13 kPa

(4 in-Hg) range at idle speed, the valve guides

(6510) could be worn. As engine speed is

increased, the needle will become steady if the

guides are responsible.

WEAK VALVE SPRINGS: When the needle

oscillation becomes more violent as engine rpm

is increased, weak valve springs (6513) are

indicated. The reading at idle could be relatively

steady.

10.

LATE VALVE TIMING: A steady but low reading

could be caused by late valve timing.

11. IGNITION TIMING RETARDING: Retarded

ignition timing will produce a steady but low

reading.

12.

INSUFFICIENT SPARK PLUG GAP: When plugs

are gapped too close, a regular, small pulsation

of the needle can occur.

13. INTAKE LEAK: A low, steady reading can be

caused by an intake manifold or carburetor

mounting flange gasket leak.

14.

BLOWN HEAD GASKET A regular drop of

approximately 33-50 kPa (1 O-l 5 in-Hg) can be

caused by a blown head gasket or warped head-

to-block mounting surface.

Loading...

Loading...