02-38

Engine Service, 2.3L

02-38

2.3L ENGINE SERVICE (Continued)

Oil Pump

Removal

1.

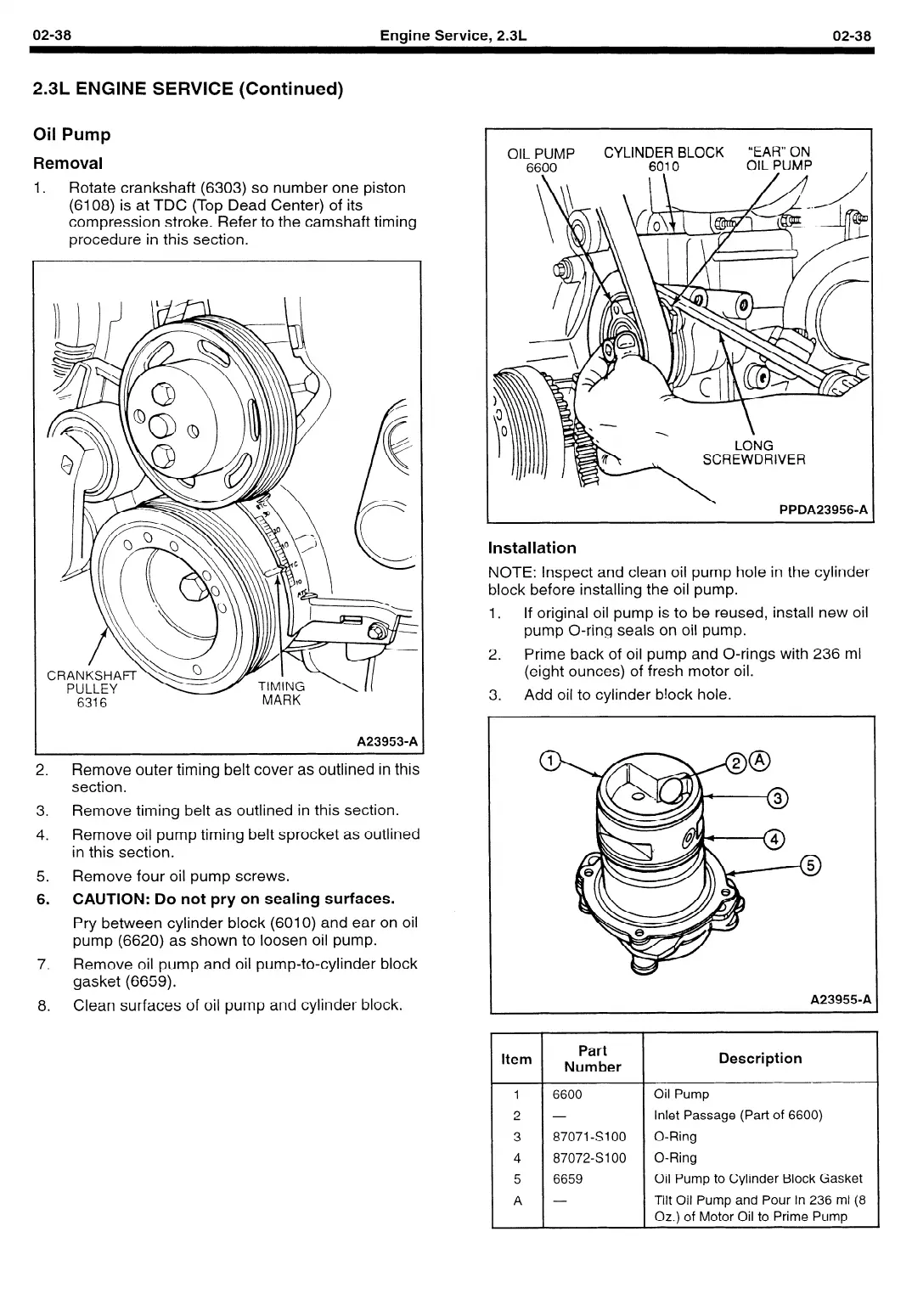

Rotate crankshaft (6303) so number one piston

(6108) is at TDC (Top Dead Center) of its

compression stroke. Refer to the camshaft timing

procedure in this section.

6316

MARK

A239530A

2. Remove outer timing belt cover as outlined in this

section.

;

3. Remove timing belt as outlined in this section.

4. Remove oil pump timing belt sprocket as outlined

in this section.

5. Remove four oil pump screws.

6.

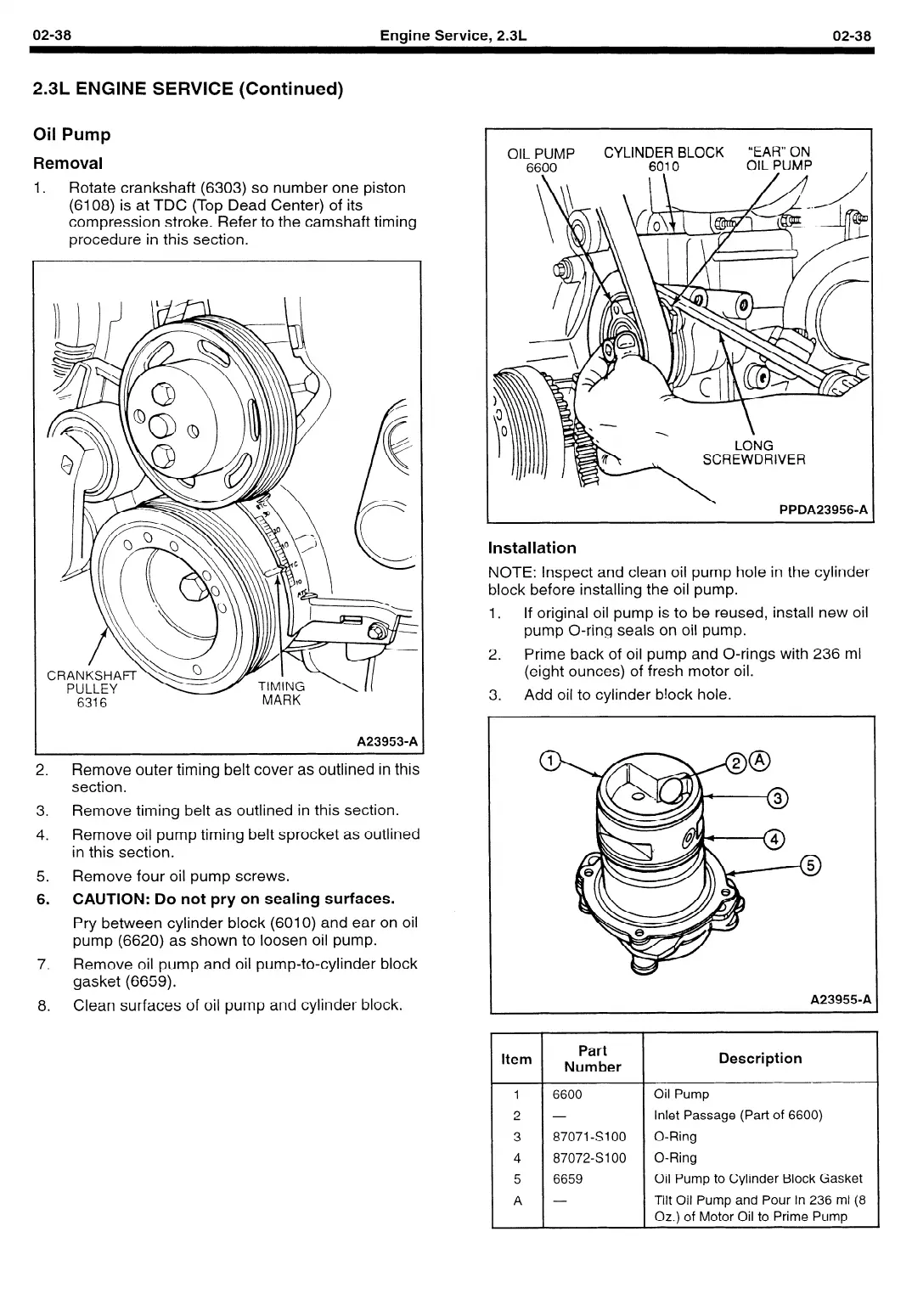

CAUTION: Do not pry on sealing surfaces.

Pry between cylinder block (6010) and ear on oil

pump (6620) as shown to loosen oil pump.

7.

Remove oil pump and oil pump-to-cylinder block

gasket (6659).

8. Clean surfaces of oil pump and cylinder block.

OIL PUMP

CYLINDER BLOCK

“EAR” ON

6600

6010

OIL PUMP

1

r

\

LONG

SCREWDRIVER

PPDA23956-A

Installation

NOTE: Inspect and clean oil pump hole in the cylinder

block before installing the oil pump.

1.

If original oil pump is to be reused, install new oil

pump O-ring seals on oil pump.

2.

Prime back of oil pump and O-rings with 236 ml

(eight ounces) of fresh motor oil.

3.

Add oil to cylinder block hole.

A23955-A

I

5 1

6659

Description

Oil Pump

Inlet Passage (Part of 6600)

O-Ring

O-Ring

Oil Pump to Cylinder Block Gasket

Tilt Oil Pump and Pour In 236 ml (8

Oz.) of Motor Oil to Prime Pump

Loading...

Loading...