02-61 Engine Service, 2.3L

02-61

DISASSEMBLY AND ASSEMBLY (Continued)

Hydraulic Lash Adjuster

Disassembly and Assembly

NOTE: Do not mix parts between different lash

adjusters. Parts are select-fit and not interchangeable.

1.

Remove snap ring.

2.

Remove fulcrum, plunger, and spring.

3. Clean to remove all traces of motor oil and

varnish. Make sure check ball is free.

4. To assemble, lubricate parts with clean Super

Premium Motor Oil X0-5W30-QSP or equivalent,

meeting Ford specification ESE-M2CI 53-E and

reverse disassembly steps. If it is necessary to

store lash adjusters for some time before

installation, protect them from dust and dirt. If not

kept clean, they may stick during operation.

5.

Perform leak-down test as outlined in the engine

service section.

Cylinder Block, Bare

Before replacing a cylinder block (6010), determine if it

is repairable. If so, make the necessary repairs

following the procedures given in the engine service

section.

Disassembly

1. Completely disassemble the old engine, following

the engine disassembly procedure in this section.

2. Remove core plugs as outlined in the engine

service section.

3.

Remove oil gallery pipe plugs.

4. NOTE: A rifle-cleaning brush is helpful for

cleaning engine oil galleries.

Clean cylinder block and inspect as outlined in

the engine service section.

Assembly

1.

If using new or reconditioned cylinder block,

uncrate and clean preservative materials

according to the supplier’s instructions.

2.

Position the new cylinder block in a work stand

and install all serviceable parts removed from the

old cylinder block, following engine assembly

procedure in this section.

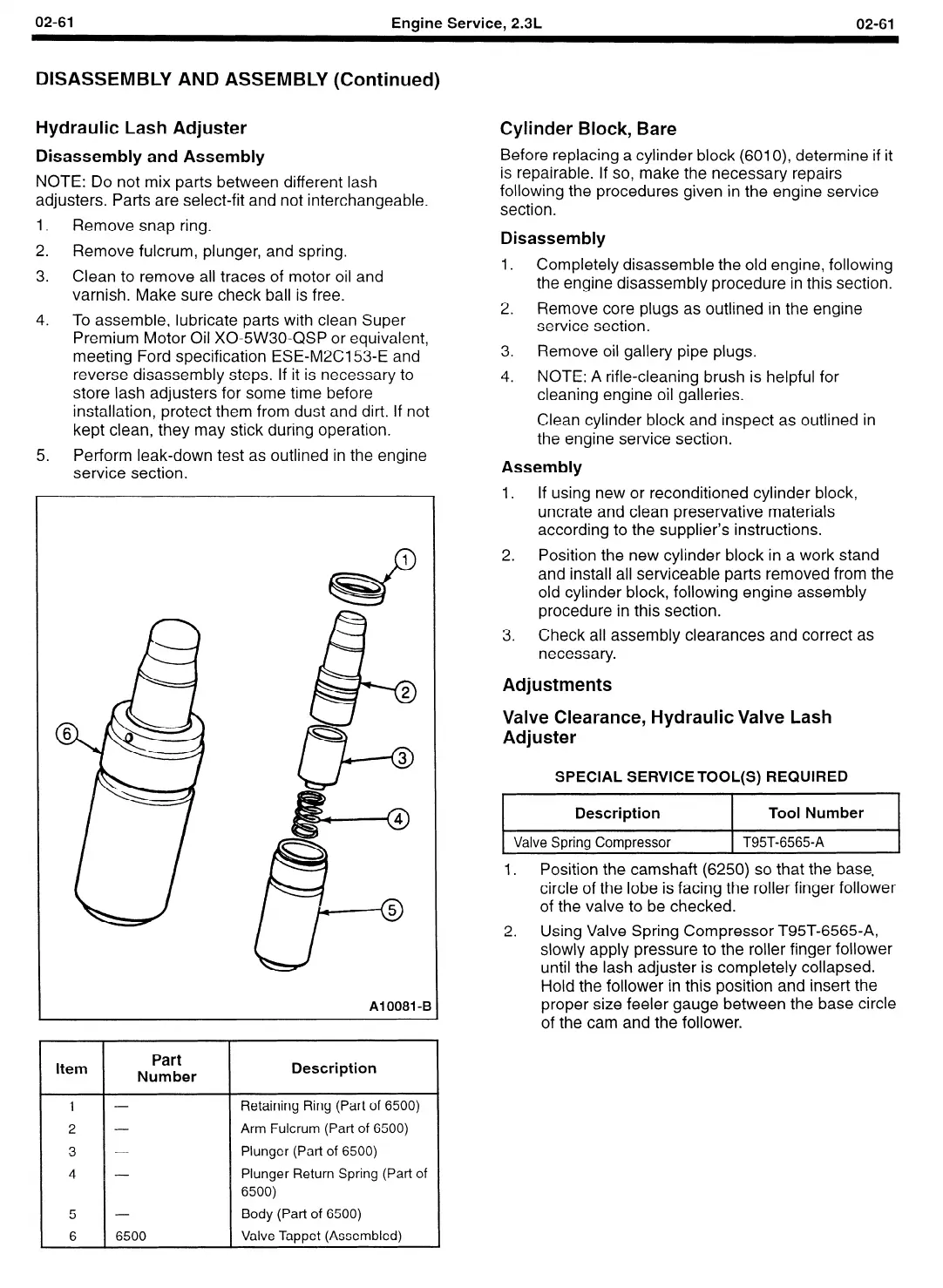

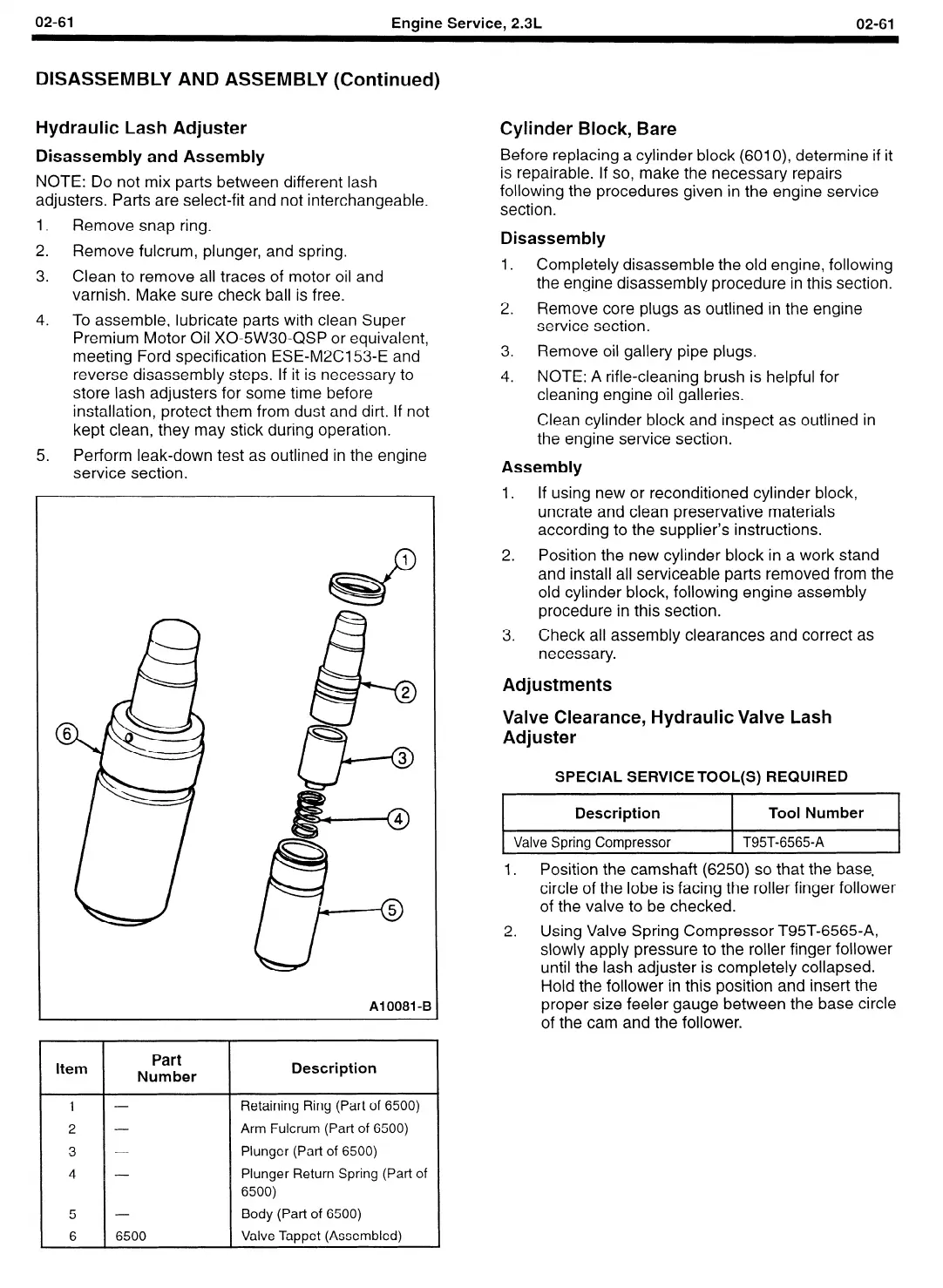

Al0081-E

Item

Part

Number

Description

5

6

6500

2. Using Valve Spring Compressor T95T-6565-A,

slowly apply pressure to the roller finger follower

until the lash adjuster is completely collapsed.

Hold the follower in this position and insert the

proper size feeler gauge between the base circle

of the cam and the follower.

Retaining Ring (Part of 6500)

Arm Fulcrum (Part of 6500)

Plunger (Part of 6500)

Plunger Return Spring (Part of

6500)

Body (Part of 6500)

Valve Tappet (Assembled)

3.

Check all assembly clearances and correct as

necessary.

Adjustments

Valve Clearance, Hydraulic Valve Lash

Adjuster

SPECIAL SERVICE TOOL(S) REQUIRED

.

Description

Tool Number

Valve Spring Compressor

T95T-6565-A

1.

Position the camshaft (6250) so that the base,

circle of the lobe is facing the roller finger follower

of the valve to be checked.

Loading...

Loading...