01-27

Engine Service

01-27

SERVICE PROCEDURES (Continued)

8.

Remove fluid from cup and bleed fluid from

tappet by working plunger up and down. This

step will aid in depressing tappet plungers when

checking valve clearance.

9.

If a valve tappet is not within specifications:

l

Replace defective valve tappets with new

ones. It is not necessary to disassemble and

clean new valve tappets to test them since

they are shipped with testing fluid.

Oil Pan

Cleaning

Scrape any dirt or metal particles from the inside of the

oil pan. Scrape all old gasket material from the gasket

surface. Wash the pan in a solvent and dry it

thoroughly. Make sure all foreign particles are

removed.

Inspection

Check the oil pan for cracks, holes or damaged drain

plug threads. Check the gasket surface for damage

caused by over-tightened bolts. Replace with a new oil

pan (6675) if repairs cannot be made.

Cylinder Heads

NOTE: Do not plane or grind more than 0.254mm

(0.010 inch) from original cylinder head gasket

surface.

Replace the cylinder head (6049) if it is cracked.

Remove all burrs or scratches with an oil stone.

Cleaning

With the valves installed to protect the valve seats,

remove deposits from the combustion chambers and

valve heads with a scraper and a wire brush. Be

careful not to damage the cylinder head gasket

surface. After the valves are removed, clean the valve

guide bores. Use cleaning solvent to remove dirt,

grease and other deposits from the valves with a fine

wire brush or buffing wheel.

Inspection

Inspect the cylinder head for cracks or excessively

burned areas in the exhaust outlet ports.

Check the cylinder head for cracks and inspect the

gasket surface for burrs and nicks. Small

imperfections of this type can be dressed down using

an oil stone. Replace the cylinder head if it is cracked.

The following inspection procedures are for a cylinder

head that is to be completely overhauled. For

individual repair operations, use only the pertinent

inspection procedure.

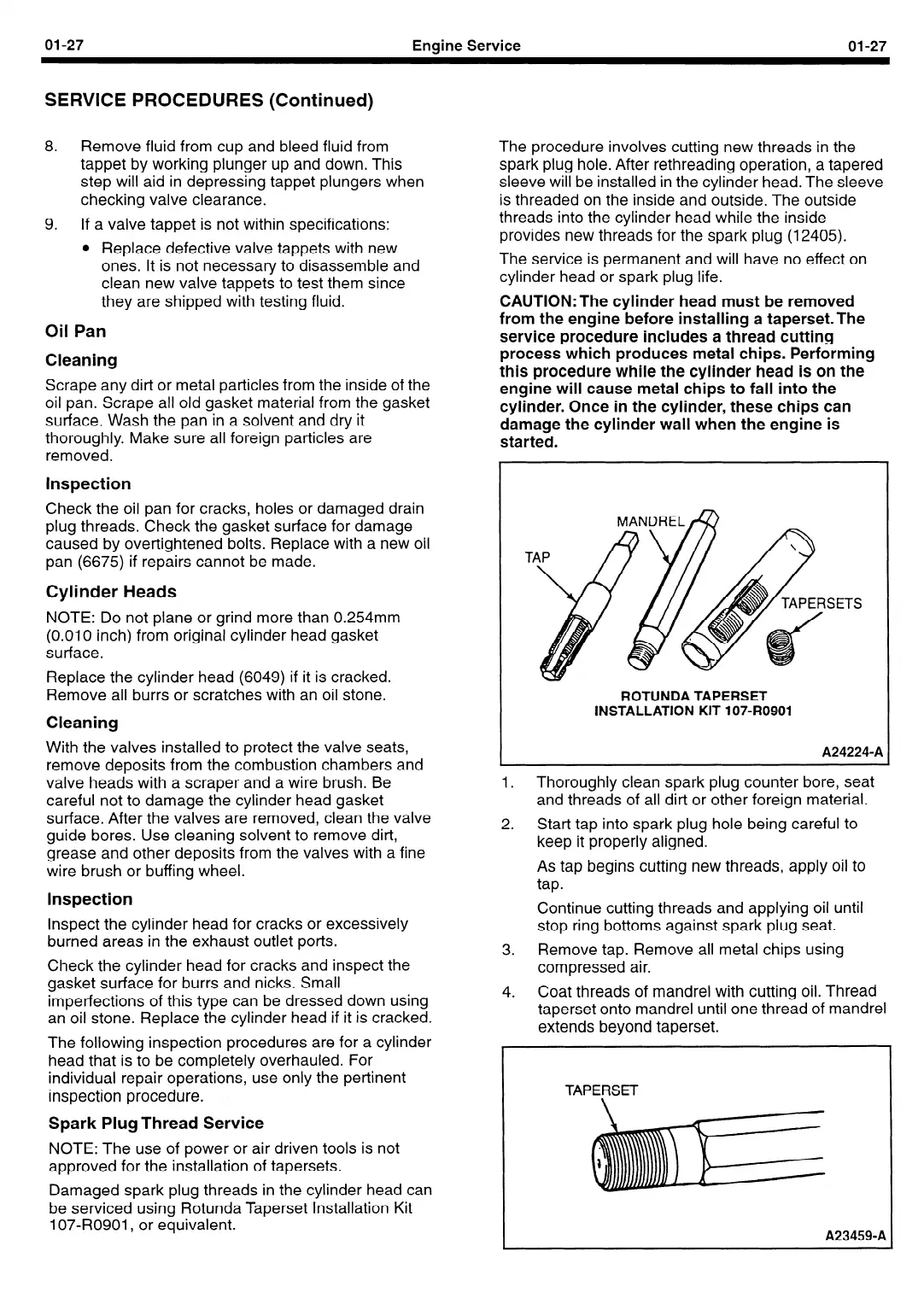

Spark Plug Thread Service

NOTE: The use of power or air driven tools is not

approved for the installation of tapersets.

Damaged spark plug threads in the cylinder head can

be serviced using Rotunda Taperset Installation Kit

107-R0901,

or equivalent.

The procedure involves cutting new threads in the

spark plug hole. After rethreading operation, a tapered

sleeve will be installed in the cylinder head. The sleeve

is threaded on the inside and outside. The outside

threads into the cylinder head while the inside

provides new threads for the spark plug

(12405).

The service is permanent and will have no effect on

cylinder head or spark plug life.

CAUTION:The

cylinder head must be removed

from the engine before installing a taperset.The

service procedure includes a thread cutting

process which produces metal chips. Performing

this procedure while the cylinder head is on the

engine will cause metal chips to fall into the

cylinder. Once in the cylinder, these chips can

damage the cylinder wall when the engine is

started.

SETS

ROTUNDA TAPERSET

INSTALLATION KIT 107-R0901

A24224-A

I.

Thoroughly clean spark plug counter bore, seat

and threads of all dirt or other foreign material.

2.

Start tap into spark plug hole being careful to

keep it properly aligned.

As tap begins cutting new threads, apply oil to

tap.

Continue cutting threads and applying oil until

stop ring bottoms against spark plug seat.

3.

Remove tap. Remove all metal chips using

compressed air.

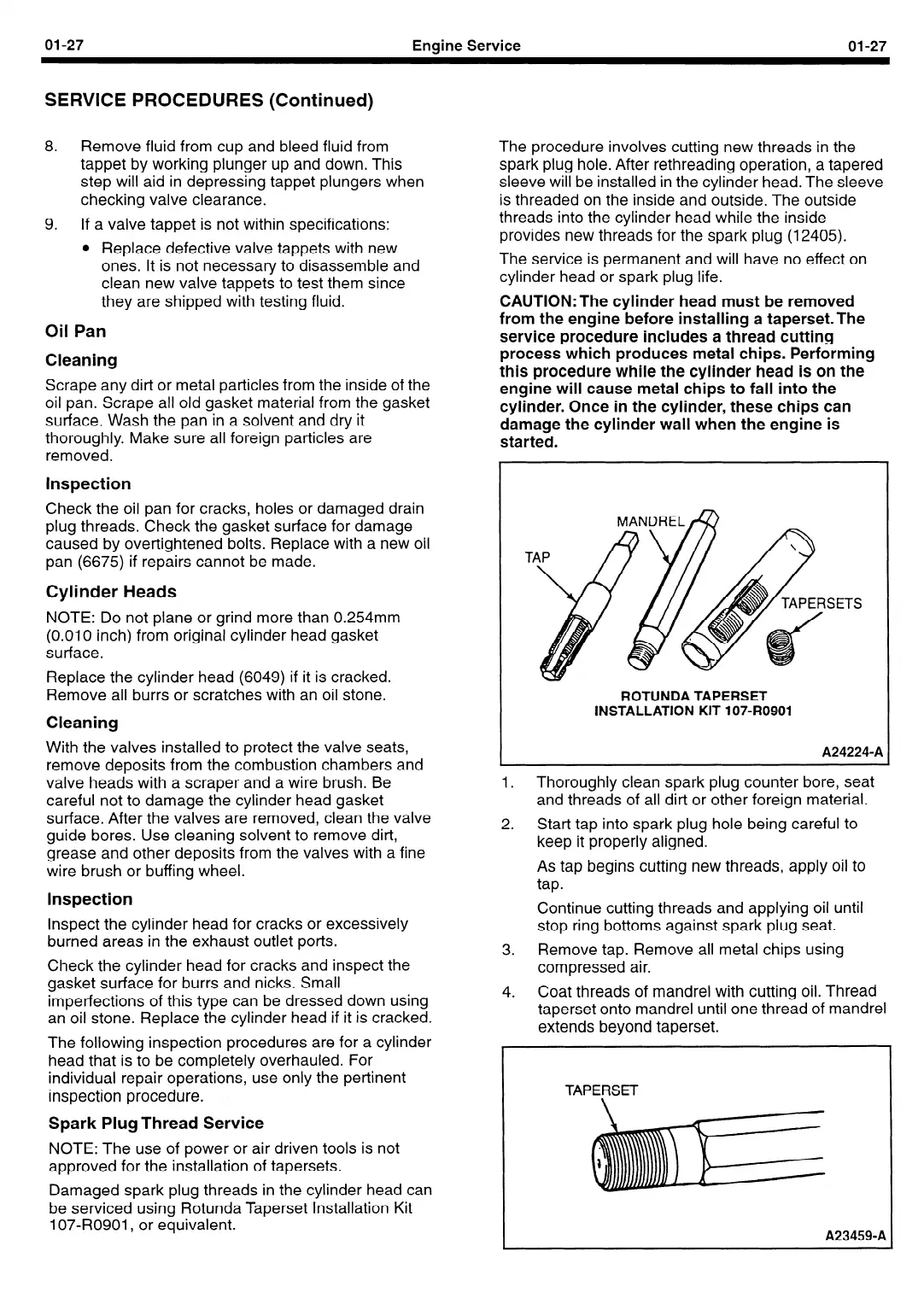

4.

Coat threads of mandrel with cutting oil. Thread

taperset onto mandrel until one thread of mandrel

extends beyond taperset.

TAPERSET

A23459-A

Loading...

Loading...