02-I 4

Engine Service, 2.3L

02-I 4

2.3L ENGINE SERVICE (Continued)

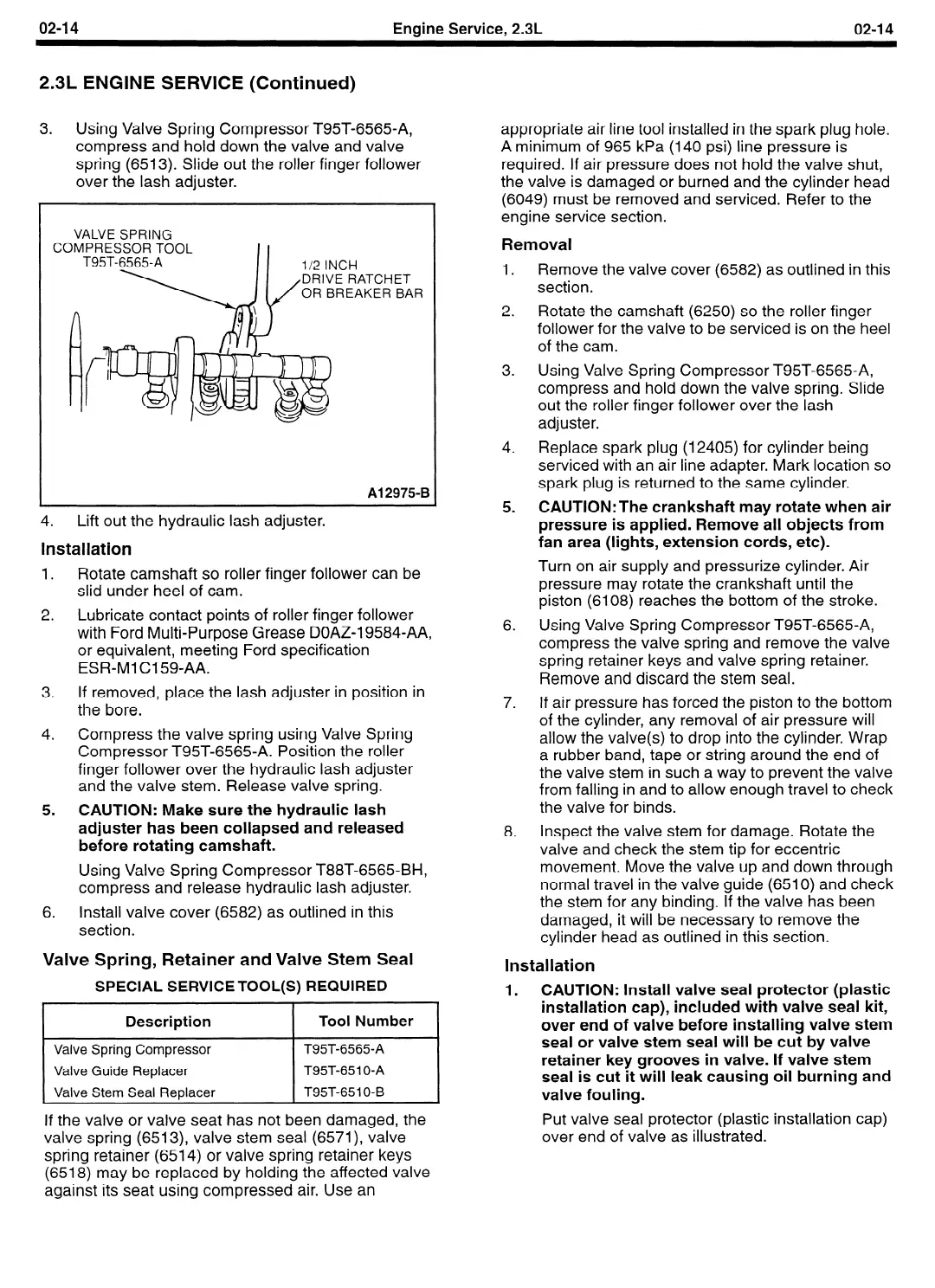

3.

Using Valve Spring Compressor T95T-6565-A,

compress and hold down the valve and valve

spring (6513). Slide out the roller finger follower

over the lash adjuster.

VALVE SPRING

COMPRESSOR TOOL

I I

T95T-6565-A

l/2 INCH

DRIVE RATCHET

OR BREAKER BAR

Al 2975-B

4.

Lift out the hydraulic lash adjuster.

Installation

1.

Rotate camshaft so roller finger follower can be

slid under heel of cam.

2.

Lubricate contact points of roller finger follower

with Ford Multi-Purpose Grease DOAZ-19584-AA,

or equivalent, meeting Ford specification

ESR-Ml Cl 599AA.

3.

If removed, place the lash adjuster in position in

the bore.

4.

Compress the valve spring using Valve Spring

Compressor T95T-6565-A. Position the roller

finger follower over the hydraulic lash adjuster

and the valve stem. Release valve spring.

5.

CAUTION:

Make sure the hydraulic lash

adjuster has been collapsed and released

before rotating camshaft.

Using Valve Spring Compressor T88T-6565-BH,

compress and release hydraulic lash adjuster.

6.

Install valve cover (6582) as outlined in this

section.

Valve Spring, Retainer and Valve Stem Seal

SPECIAL SERVICE TOOL(S) REQUIRED

Description

I

Tool Number

Valve Spring Compressor

Valve Guide Replacer

Valve Stem Seal Replacer

T95T-6565-A

T95T-651 O-A

T95T-651 O-B

If the valve or valve seat has not been damaged, the

valve spring (6513), valve stem seal (6571), valve

spring retainer (6514) or valve spring retainer keys

(6518) may be replaced by holding the affected valve

against its seat using compressed air. Use an

appropriate air line tool installed in the spark plug hole.

A minimum of 965 kPa (140 psi) line pressure is

required. If air pressure does not hold the valve shut,

the valve is damaged or burned and the cylinder head

(6049) must be removed and serviced. Refer to the

engine service section.

Removal

1.

2.

3.

4.

5.

6.

7.

8.

Remove the valve cover (6582) as outlined in this

section.

Rotate the camshaft (6250) so the roller finger

follower for the valve to be serviced is on the heel

of the cam.

Using Valve Spring Compressor T95T-6565-A,

compress and hold down the valve spring. Slide

out the roller finger follower over the lash

adjuster.

Replace spark plug (12405) for cylinder being

serviced with an air line adapter. Mark location so

spark plug is returned to the same cylinder.

CAUTION:The crankshaft may rotate when air

pressure is applied. Remove all objects from

fan area (lights, extension cords, etc).

Turn on air supply and pressurize cylinder. Air

pressure may rotate the crankshaft until the

piston (6108) reaches the bottom of the stroke.

Using Valve Spring Compressor T95T-6565-A,

compress the valve spring and remove the valve

spring retainer keys and valve spring retainer.

Remove and discard the stem seal.

If air pressure has forced the piston to the bottom

of the cylinder, any removal of air pressure will

allow the valve(s) to drop into the cylinder. Wrap

a rubber band, tape or string around the end of

the valve stem in such a way to prevent the valve

from falling in and to allow enough travel to check

the valve for binds.

Inspect the valve stem for damage. Rotate the

valve and check the stem tip for eccentric

movement. Move the valve up and down through

normal travel in the valve guide (6510) and check

the stem for any binding. If the valve has been

damaged, it will be necessary to remove the

cylinder head as outlined in this section.

Installation

1.

CAUTION: Install valve seal protector (plastic

installation cap), included with valve seal kit,

over end of valve before installing valve stem

seal or valve stem seal will be cut by valve

retainer key grooves in valve. If valve stem

seal is cut it will leak causing oil burning and

valve fouling.

Put valve seal protector (plastic installation cap)

over end of valve as illustrated.

Loading...

Loading...