01-25

Engine Service

01-25

SERVICE PROCEDURES (Continued)

Camshaft Bearing Journals

1.

Measure each journal twice, 90 degrees apart, to

determine journal wear, size, and out-of-round.

2. Check measurements against specifications in

the specification section.

3. If journals are excessively out-of-round or worn,

regrind to a standard undersize. Refer to Master

Parts Catalogue. If journals are too worn to be

refinished to an available undersize, replace

camshaft.

Camshaft Journals Oil Clearance

1.

Measure camshaft bearings and camshaft

bearing journals as outlined in this section.

2. Subtract size of journal from the size of its

bearing.

3.

Check clearance against specifications in

specification section.

4.

If clearance is excessive, but camshaft journals

are within specifications, simply install new

bearings. If both bearings and journals are worn,

turn camshaft journals to a standard undersize

and install new undersize bearings.

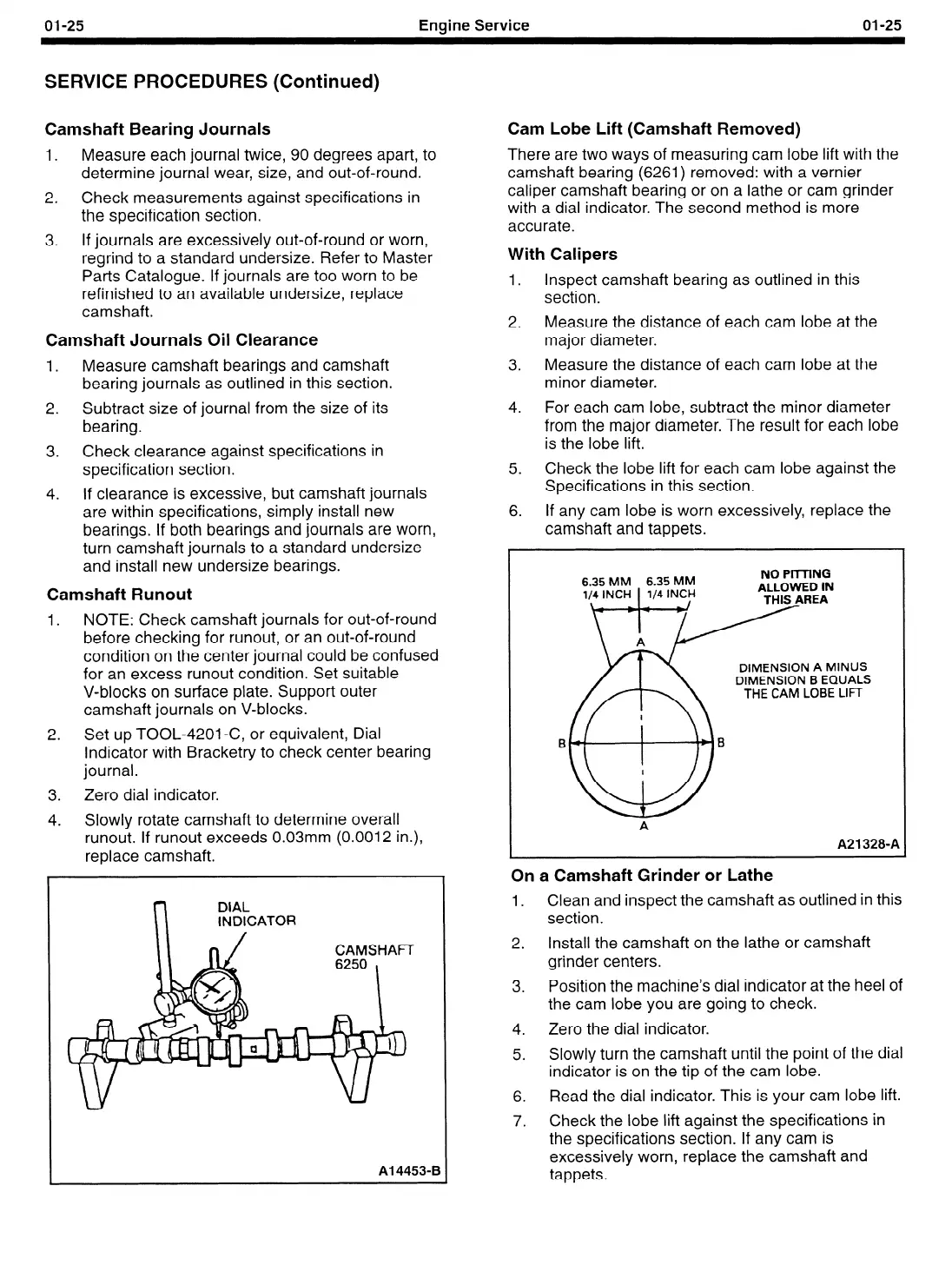

Camshaft Runout

1.

NOTE: Check camshaft journals for out-of-round

before checking for runout, or an out-of-round

condition on the center journal could be confused

for an excess runout condition. Set suitable

V-blocks on surface plate. Support outer

camshaft journals on V-blocks.

2.

Set up TOOL-4201-C, or equivalent, Dial

Indicator with Bracketry to check center bearing

journal.

3.

Zero dial indicator.

4.

Slowly rotate camshaft to determine overall

runout. If runout exceeds 0.03mm (0.0012 in.),

replace camshaft.

n

DIAL

INDICATOR

Al 4453-B

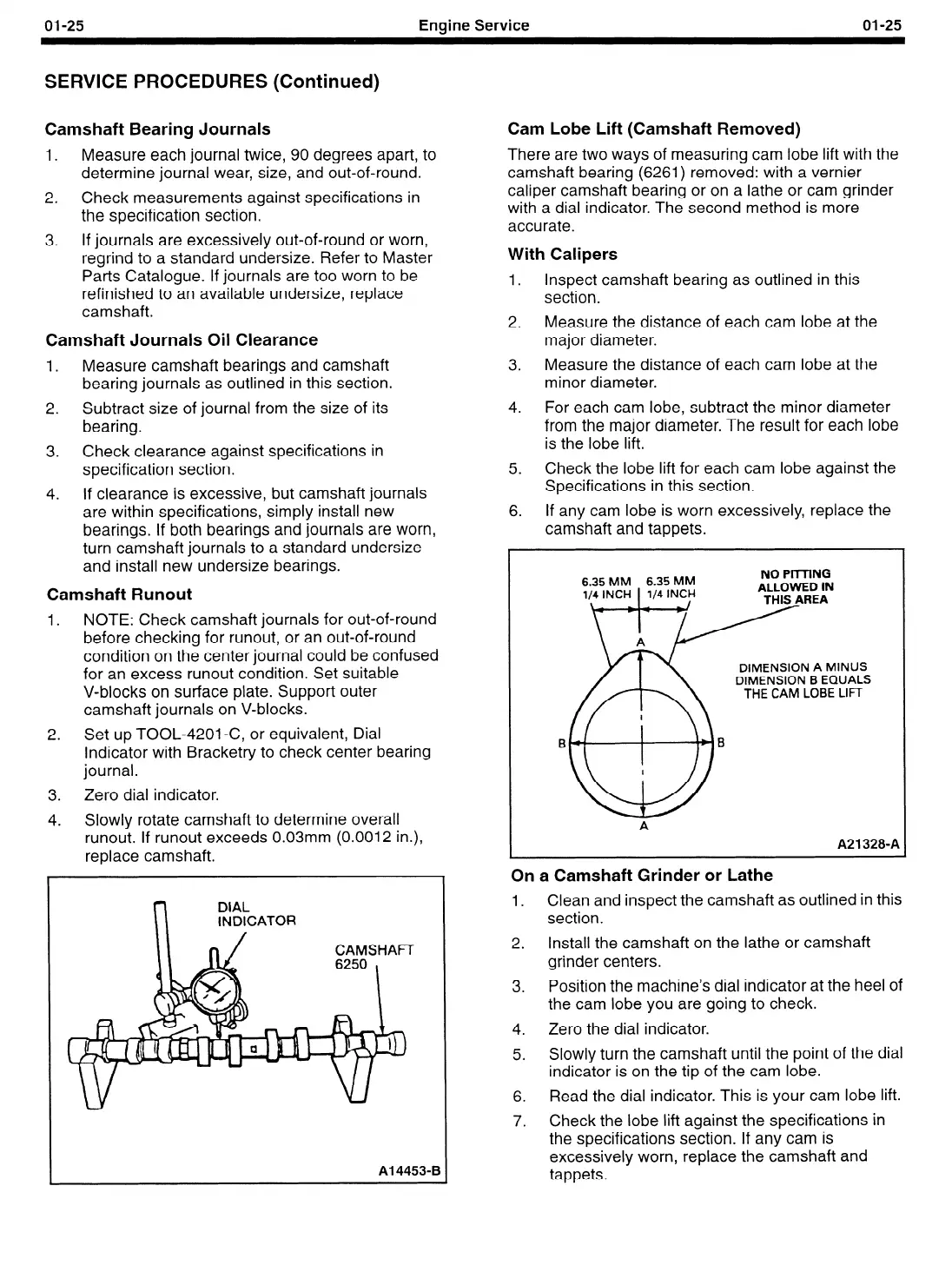

Cam Lobe Lift (Camshaft Removed)

There are two ways of measuring cam lobe lift with the

camshaft bearing (6261) removed: with a vernier

caliper camshaft bearing or on a lathe or cam grinder

with a dial indicator. The second method is more

accurate.

With Calipers

1.

Inspect camshaft bearing as outlined in this

section.

2.

Measure the distance of each cam lobe at the

major diameter.

3.

Measure the distance of each cam lobe at the

minor diameter.

4.

For each cam lobe, subtract the minor diameter

from the major diameter. The result for each lobe

is the lobe lift.

5.

Check the lobe lift for each cam lobe against the

Specifications in this section.

6.

If any cam lobe is worn excessively, replace the

camshaft and tappets.

6.35 MM 6.35 MM

NO Pi-lTlNG

li”CHff4 lN;zf

DIMENSION A MINUS

DIMENSION B EQUALS

THE CAM LOBE LIFT

A

A21 328-A

On a Camshaft Grinder or Lathe

1. Clean and inspect the camshaft as outlined in this

section.

2.

Install the camshaft on the lathe or camshaft

grinder centers.

3.

Position the machine’s dial indicator at the heel of

the cam lobe you are going to check.

4.

Zero the dial indicator.

5.

Slowly turn the camshaft until the point of the dial

indicator is on the tip of the cam lobe.

6.

Read the dial indicator. This is your cam lobe lift.

7.

Check the lobe lift against the specifications in

the specifications section. If any cam is

excessively worn, replace the camshaft and

tappets.

Loading...

Loading...