02-52

Engine Service, 2.3L

02-52

2.3L ENGINE SERVICE (Continued)

12. Check ring gaps using the procedure given in the

engine service section.

13. NOTE: Never install compression rings on

pistons by hand. Always use a ring expander tool.

Install rings using a ring expander tool. Check

ring side clearance.

14. Clean crankshaft journals.

15. If necessary, disassemble piston and rod

assemblies as outlined in this section.

16. Clean gasket surfaces and fasteners.

installation

1. If disassembled, assemble piston and connecting

rod assembly as outlined in this section.

2. Refer to Pistons, Piston Pins, and Piston Rings in

the engine service section for Cleaning,

Inspection, Pistons -

Fitting, and Piston Rings

- Fitting.

3. If necessary, install piston and pin on connecting

rod as outlined in this section.

4.

Using a piston ring expander, install the piston

rings, starting with the oil control rings. Make sure

rings are installed right side up. Refer to

instructions with piston ring set.

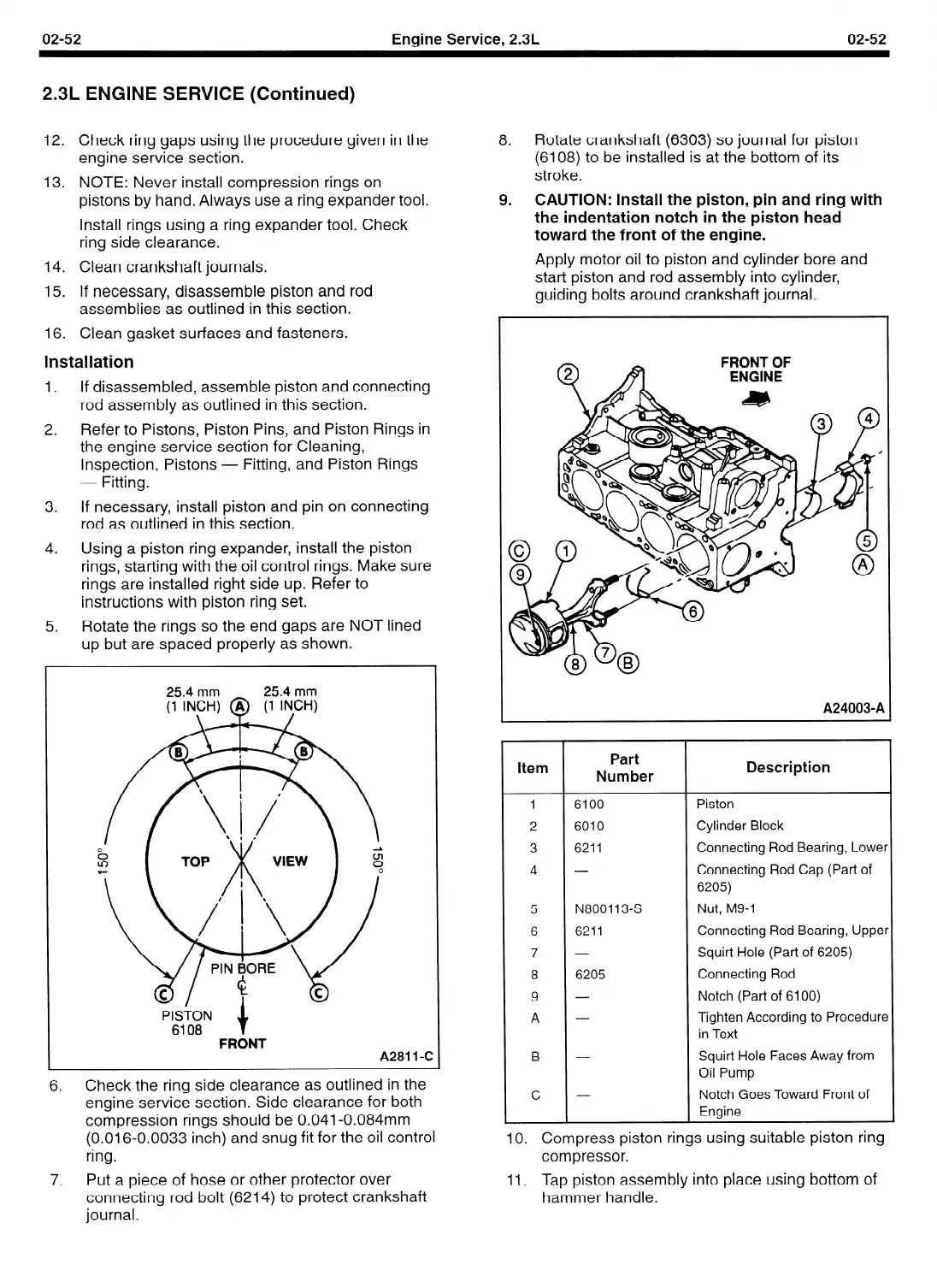

5.

Rotate the rings so the end gaps are NOT lined

up but are spaced properly as shown.

FRONT

A281

1 -c

6.

Check the ring side clearance as outlined in the

engine service section. Side clearance for both

compression rings should be 0.041-0.084mm

(0.016-0.0033 inch) and snug fit for the oil control

rrng.

7. Put a piece of hose or other protector over

connecting rod bolt (6214) to protect crankshaft

journal.

8.

Rotate crankshaft (6303) so journal for piston

(6108) to be installed is at the bottom of its

stroke.

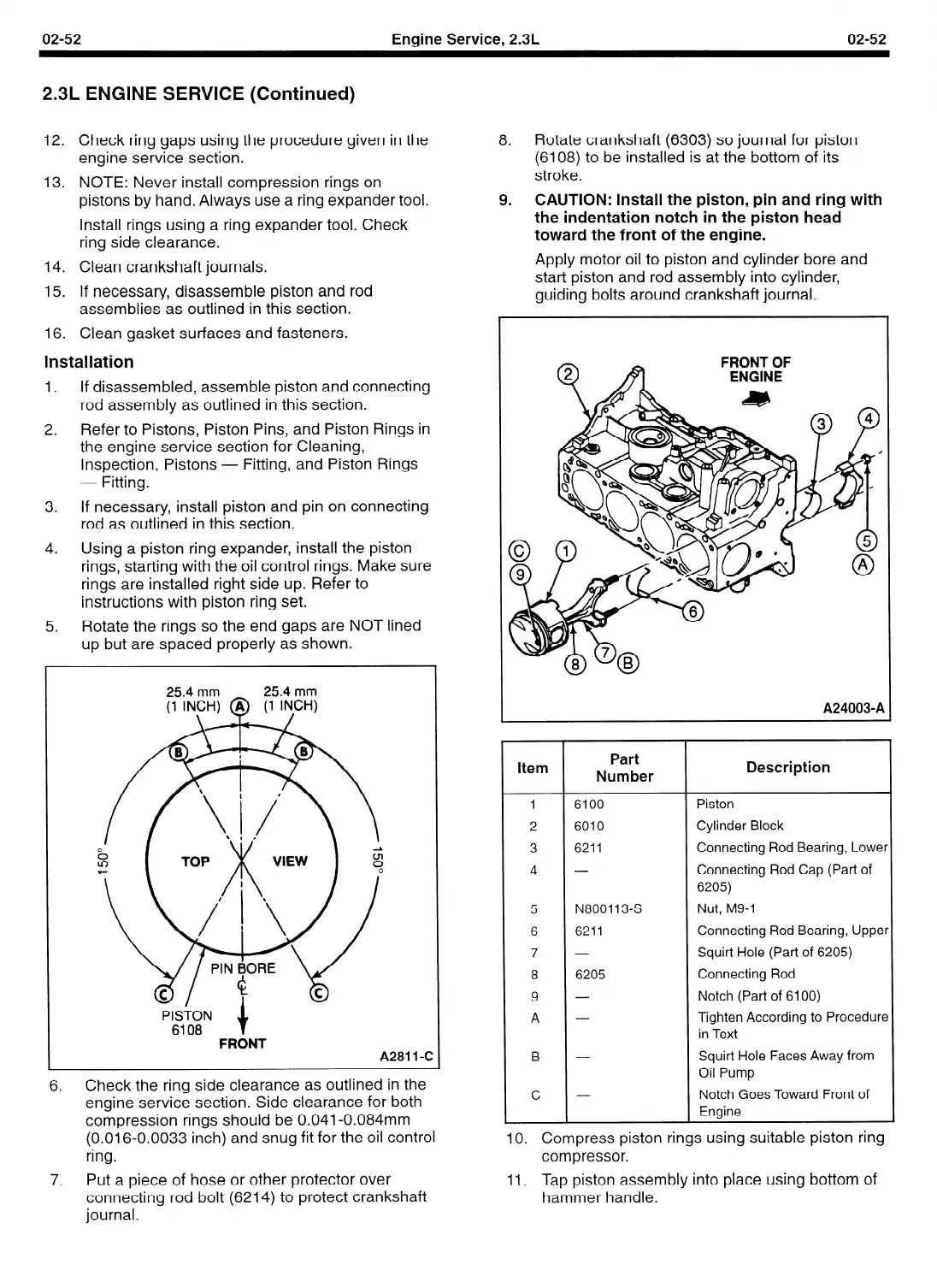

9.

CAUTION: Install the piston, pin and ring with

the indentation notch in the piston head

toward the front of the engine.

Apply motor oil to piston and cylinder bore and

start piston and rod assembly into cylinder,

guiding bolts around crankshaft journal.

FRONT OF

ENGINE

A24003-A

Item

Part

Number

Description

1 6100

Piston

2 6010

Cylinder Block

3

6211

Connecting Rod Bearing, Lower

4 -

Connecting Rod Cap (Part of

6205)

5

N800113-s

Nut, M9-1

6 6211

Connecting Rod Bearing, Upper

7 -

Squirt Hole (Part of 6205)

8

6205

Connecting Rod

9 -

Notch (Part of 6100)

A -

Tighten According to Procedure

in Text

B -

Squirt Hole Faces Away from

Oil Pump

c -

Notch Goes Toward Front of

Engine

10.

Compress piston rings using suitable piston ring

compressor.

11. Tap piston assembly into place using bottom of

hammer handle.

Loading...

Loading...