02-62 Engine Service, 2.3L

02-62

DISASSEMBLY AND ASSEMBLY (Continued)

CC

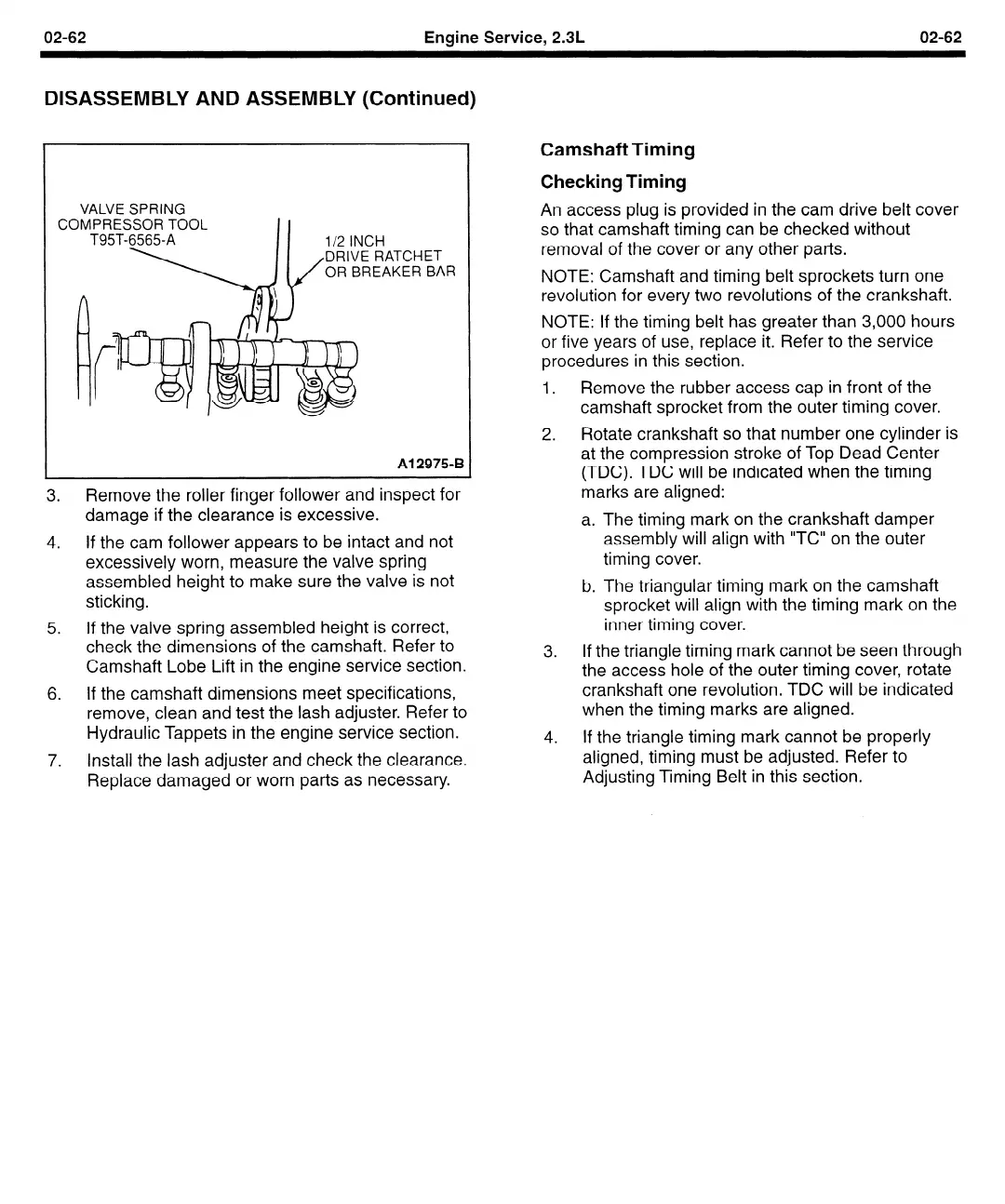

VALVE SPRING

IMPRESSOR TOOL

T95T-6565-A

II

l/2 INCH

RAT

‘CHET

;EAK ER BAR

Al 2975-B

3. Remove the roller finger

follower and inspect

damage if the clearance

is excessive.

for

4. If the cam follower appears to be intact and not

excessively worn, measure the valve spring

assembled height to make sure the valve is not

sticking.

5. If the valve spring assembled height is correct,

check the dimensions of the camshaft. Refer to

Camshaft Lobe Lift in the engine service section.

6. If the camshaft dimensions meet specifications,

remove, clean and test the lash adjuster. Refer to

Hydraulic Tappets in the engine service section.

7. Install the lash adjuster and check the clearance.

Replace damaged or worn parts as necessary.

Camshaft Timing

Checking Timing

An access plug is provided in the cam drive belt cover

so that camshaft timing can be checked without

removal of the cover or any other parts.

NOTE: Camshaft and timing belt sprockets turn one

revolution for every two revolutions of the crankshaft.

NOTE: If the timing belt has greater than 3,000 hours

or five years of use, replace it. Refer to the service

procedures in this section.

1.

2.

Remove the rubber access cap in front of the

camshaft sprocket from the outer timing cover.

Rotate crankshaft so that number one cylinder is

at the compression stroke of Top Dead Center

(TDC). TDC will be indicated when the timing

marks are aligned:

a. The timing mark on the crankshaft damper

assembly will align with “TC” on the outer

timing cover.

b. The triangular timing mark on the camshaft

sprocket will align with the timing mark on the

inner timing cover.

If the triangle timing mark cannot be seen through

the access hole of the outer timing cover, rotate

crankshaft one revolution. TDC will be indicated

when the timing marks are aligned.

If the triangle timing mark cannot be properly

aligned, timing must be adjusted. Refer to

Adjusting Timing Belt in this section.

Loading...

Loading...