02-21

Engine Service, 2.3L

2.3L ENGINE SERVICE (Continued)

4.

5.

6.

7.

8.

9.

IO.

11.

12.

Install timing belt over crankshaft sprocket. Then,

proceeding counterclockwise, install timing belt

over oil pump sprocket and camshaft sprocket.

Loosen tensioner adjusting bolt allowing

tensioner pulley to press against timing belt.

NOTE: When performing the following step, do

not rotate crankshaft counterclockwise as timing

belt may jump a cog, putting camshaft out of

time.

Rotate crankshaft two revolutions clockwise.

Bring crankshaft slowly, without stopping, to

number one cylinder firing position (keyway

directly up).

Recheck timing mark alignment. Repeat the

above Steps if timing marks are not properly

aligned.

Rotate tensioner assembly against belt with

torque wrench up to 40-45 Nom (29-33 lb-ft) and

tighten adjusting bolt.

Tighten adjusting bolt to 35-45 Nom (26-33 lb-ft).

Tighten spring pivot bolt to 40-55 Nom (29-40

lb-ft).

Install outer timing belt cover as outlined in this

section.

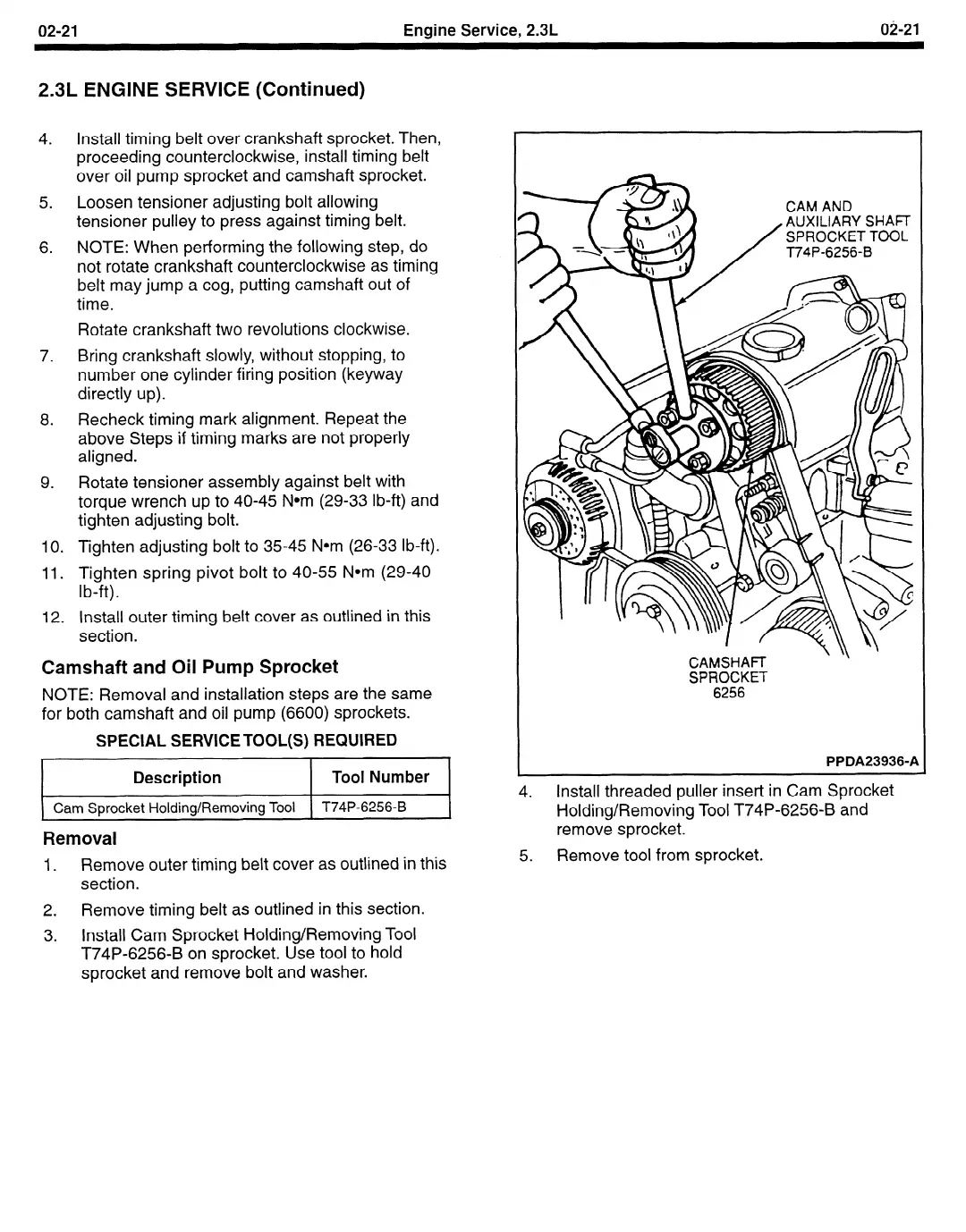

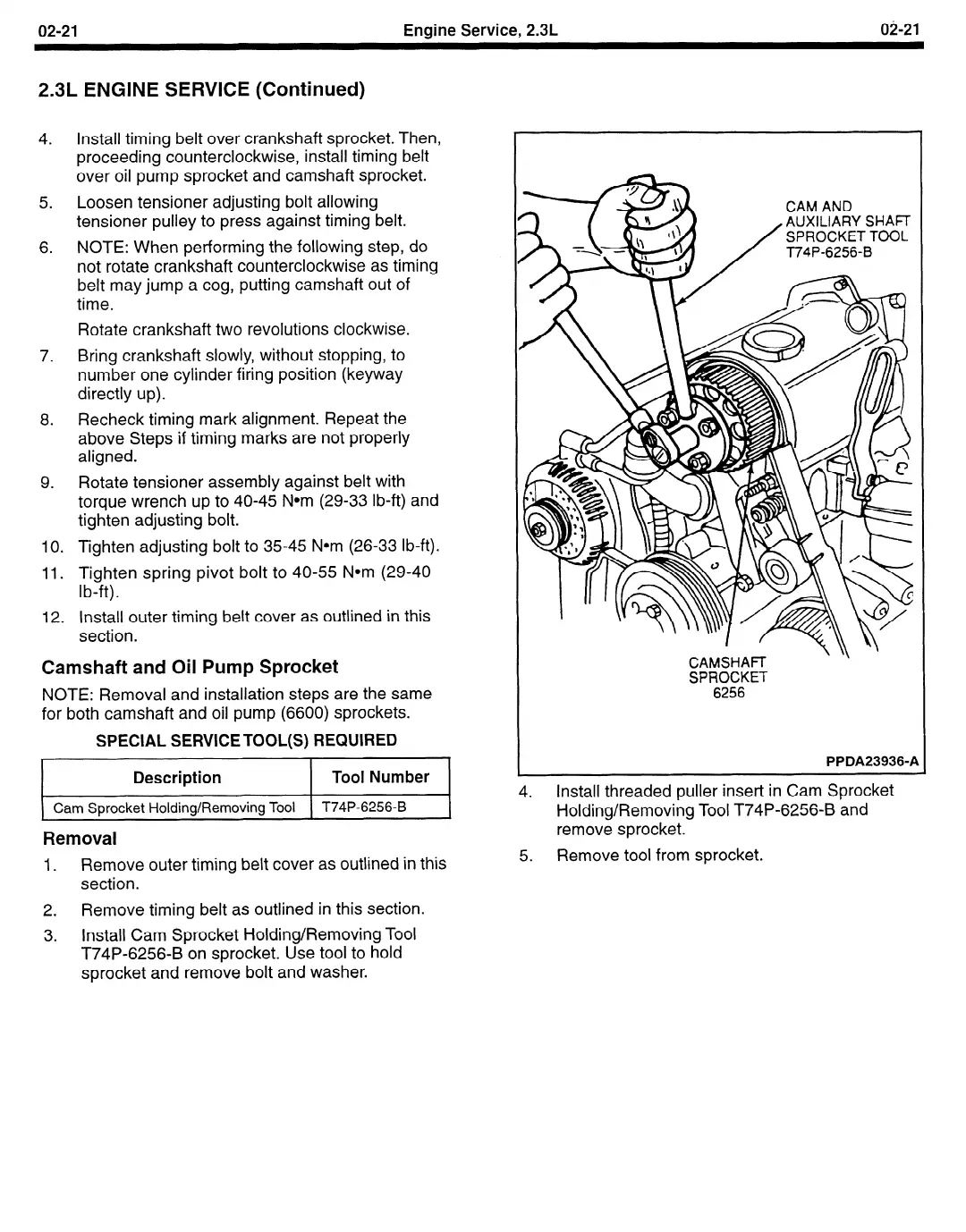

Camshaft and Oil Pump Sprocket

NOTE: Removal and installation steps are the same

for both camshaft and oil pump (6600) sprockets.

SPECIAL SERVICE TOOL(S) REQUIRED

Description Tool Number

Cam Sprocket Holding/Removing Tool

T74P-6256-B

I

Removal

1.

Remove outer timing belt cover as outlined in this

section.

2. Remove timing belt as outlined in this section.

3.

Install Cam Sprocket Holding/Removing Tool

T74P-6256-B on sprocket. Use tool to hold

sprocket and remove bolt and washer.

CAMSHAR-

SPROCKET

6256

PPDA23936-A

4. Install threaded puller insert in Cam Sprocket

Holding/Removing Tool T74P-6256-B and

remove sprocket.

5.

Remove tool from sprocket.

Loading...

Loading...