02-4

Engine Service, 2.3L

02-4

DESCRIPTION AND OPERATION (Continued)

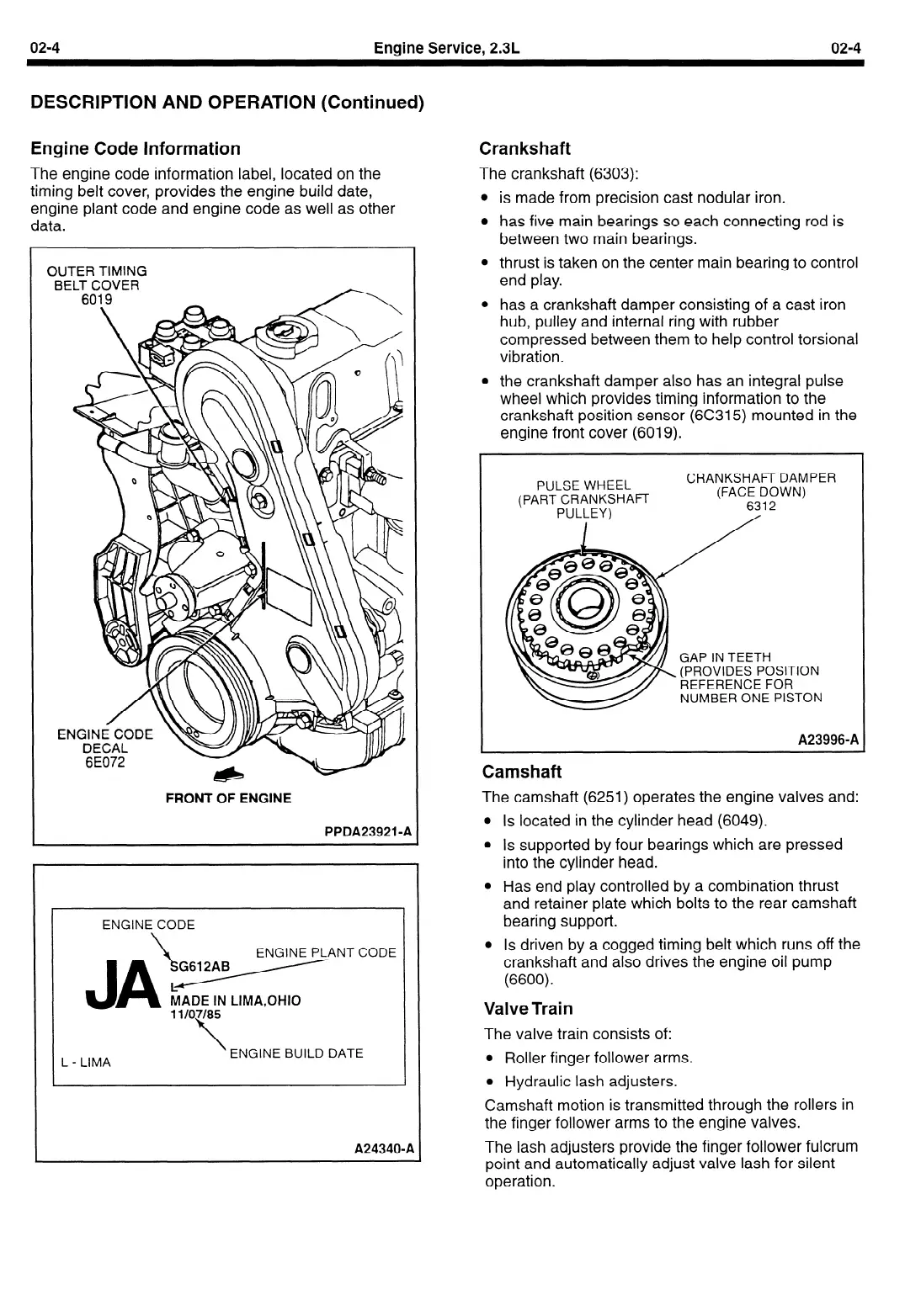

Engine Code Information

The engine code information label, located on the

timing belt cover, provides the engine build date,

engine plant code and engine code as well as other

data.

OUTER TIMING

BELT COVER

6019

FRONT OF ENGINE

PPDA23921 -P

ENGINE CODE

\

ENGINE PLANT CODE

MADE IN LIMA,OtiIO

L - LIMA

ENGINE BUILD DATE

A24340-A

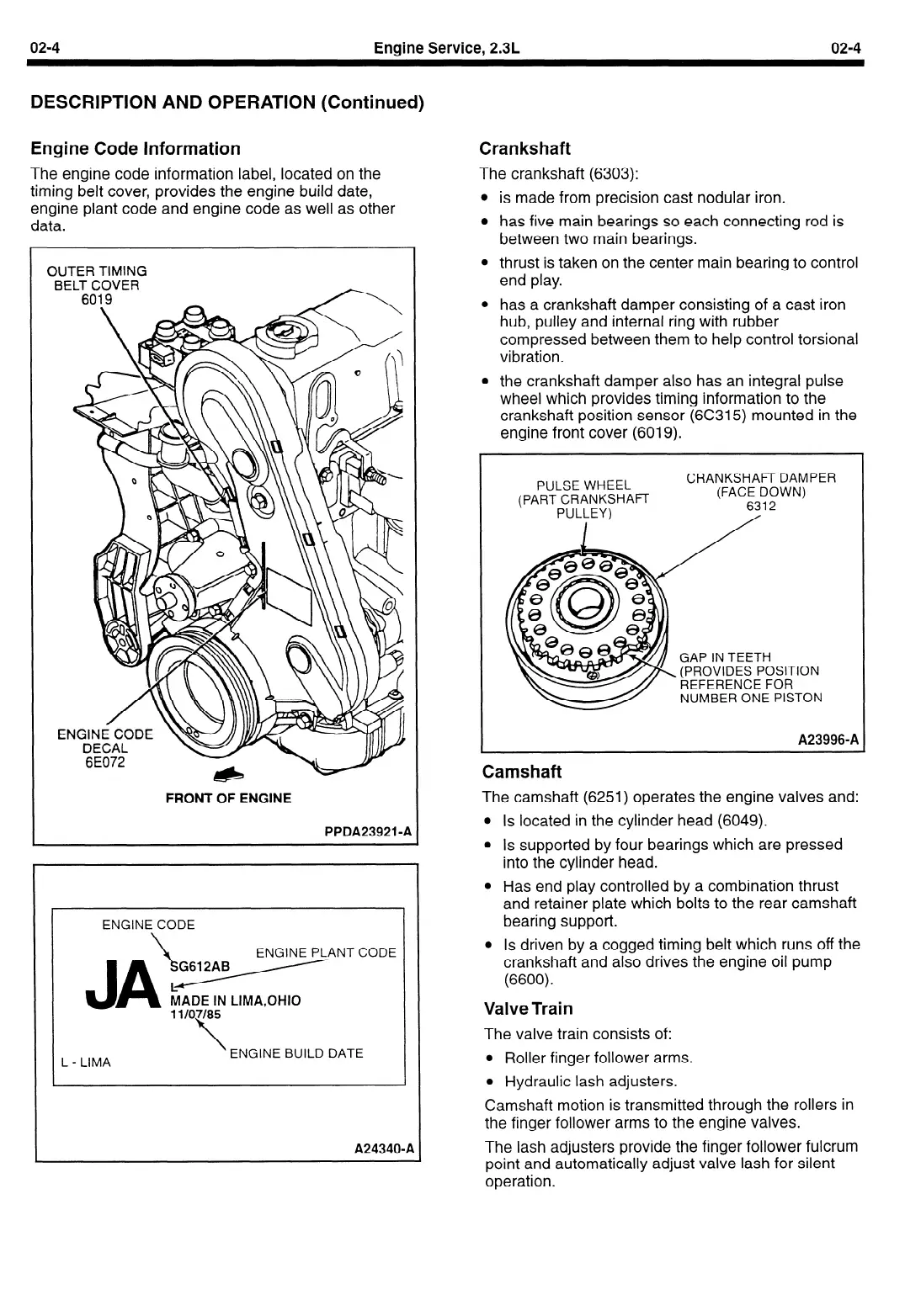

Crankshaft

The crankshaft (6303):

l

is made from precision cast nodular iron.

l

has five main bearings so each connecting rod is

between two main bearings.

l

thrust is taken on the center main bearing to control

end play.

l

has a crankshaft damper consisting of a cast iron

hub, pulley and internal ring with rubber

compressed between them to help control torsional

vibration.

l

the crankshaft damper also has an integral pulse

wheel which provides timing information to the

crankshaft position sensor (6C315) mounted in the

engine front cover (6019).

PULSE WHEEL

(PART CRANKSHAFT

PULLEY)

CRANKSHAFT DAMPER

(FACE DOWN)

6312

/

GAP IN TEETH

(PROVIDES POSITION

REFERENCE FOR

NUMBER ONE PISTON

A239960A

Camshaft

The camshaft (6251) operates the engine valves and:

l

Is located in the cylinder head (6049).

l

Is supported by four bearings which are pressed

into the cylinder head.

l

Has end play controlled by a combination thrust

and retainer plate which bolts to the rear camshaft

bearing support.

l

Is driven by a cogged timing belt which runs off the

crankshaft and also drives the engine oil pump

(6600).

Valve Train

The valve train consists of:

l

Roller finger follower arms.

l

Hydraulic lash adjusters.

Camshaft motion is transmitted through the rollers in

the finger follower arms to the engine valves.

The lash adjusters provide the finger follower fulcrum

point and automatically adjust valve lash for silent

operation.

Loading...

Loading...