03-I 9

Auxiliary Systems

03-l 9

FUEL SYSTEM DIAGNOSING AND TESTING

NOTE: For the following

tests,TEMPORARILY

place a

jumper wire across the terminals of the oil pressure

switch.

Electrical

1. Connect the positive lead of a voltmeter to the

pump power wire, and the negative lead to the

pump housing.

2. Turn on the ignition switch.

3. The voltmeter should read 12 volts. If not, check

the power supply to the pump, and the ground

wire between pump housing and engine cylinder

block.

4. ONCE YOU HAVE ESTABLISHED THE

INTEGRITY OF THE POWER SUPPLY AND

GROUND to the pump, if it still will not operate,

replace the pump assembly.

Fuel Supply and Pressure

If a problem with fuel supply or delivery is suspected,

first ensure that there is fuel in the tank. Next ensure

that the 70 micron filter inside the pump housing is

clean. Once these items have been checked and

verified, proceed as follows:

1.

Tee a pressure gauge into the fuel line at the

carburetor inlet.

2. Turn on the ignition switch, but do not start the

engine.

3.

The pump should “click” rapidly for a short time,

and pressure should build to, and level off at, 6.0

to 7.5 PSI.

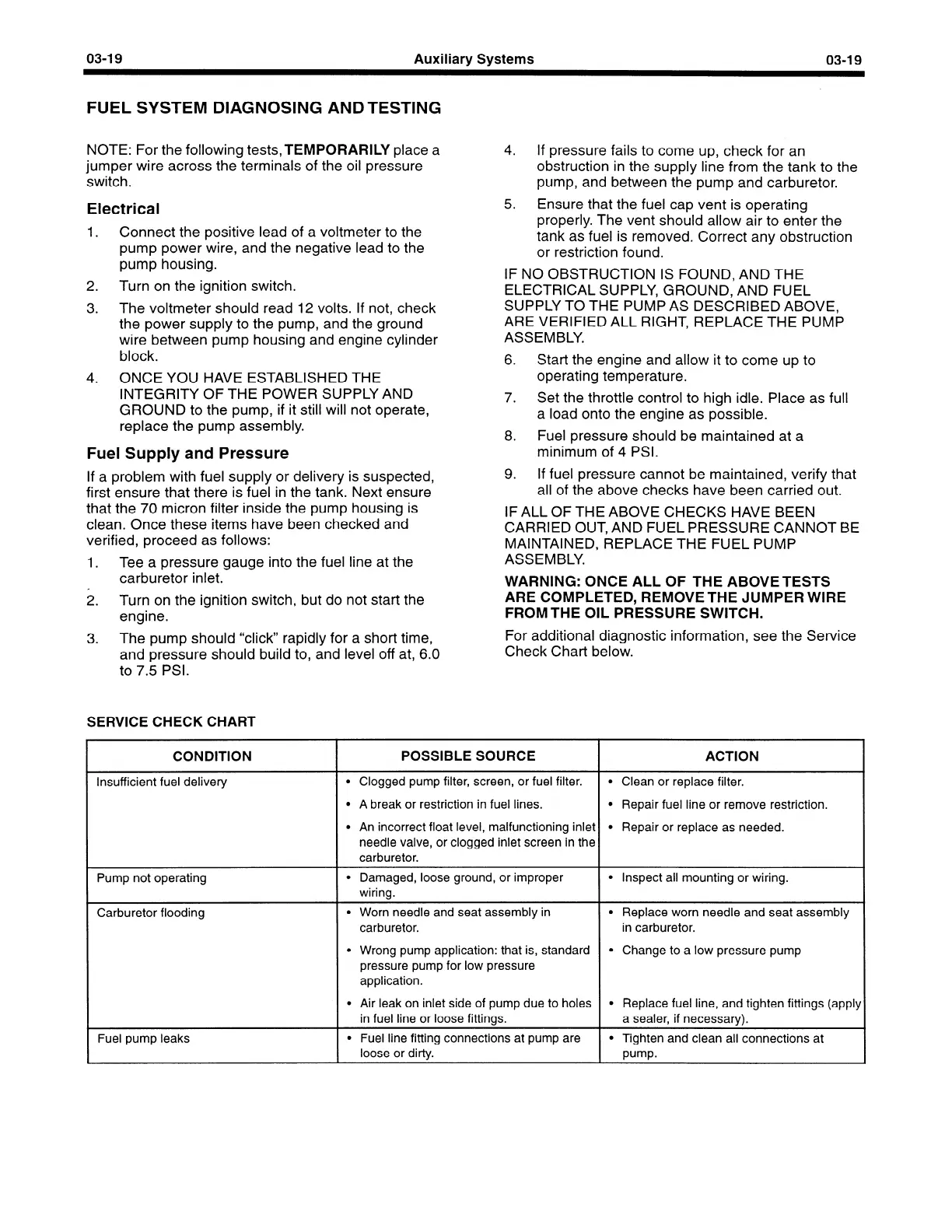

SERVICE CHECK CHART

4.

If pressure fails to come up, check for an

obstruction in the supply line from the tank to the

pump, and between the pump and carburetor.

5.

Ensure that the fuel cap vent is operating

properly. The vent should allow air to enter the

tank as fuel is removed. Correct any obstruction

or restriction found.

IF NO OBSTRUCTION IS FOUND, AND THE

ELECTRICAL SUPPLY, GROUND, AND FUEL

SUPPLY TO THE PUMP AS DESCRIBED ABOVE,

ARE VERIFIED ALL RIGHT, REPLACE THE PUMP

ASSEMBLY.

6. Start the engine and allow it to come up to

operating temperature.

7. Set the throttle control to high idle. Place as full

a load onto the engine as possible.

8. Fuel pressure should be maintained at a

minimum of 4 PSI.

9. If fuel pressure cannot be maintained, verify that

all of the above checks have been carried out.

IF ALL OF THE ABOVE CHECKS HAVE BEEN

CARRIED OUT, AND FUEL PRESSURE CANNOT BE

MAINTAINED, REPLACE THE FUEL PUMP

ASSEMBLY.

WARNING: ONCE ALL OF THE ABOVETESTS

ARE COMPLETED, REMOVE THE JUMPER WIRE

FROM THE OIL PRESSURE SWITCH.

For additional diagnostic information, see the Service

Check Chart below.

CONDITION

lnsuff icient fuel delivery

Pump not operating

Carburetor flooding

1 Fuel pump leaks

POSSIBLE SOURCE

l

Clogged pump filter, screen, or fuel filter.

l

A break or restriction in fuel lines.

l

An incorrect float level, malfunctioning inlet

needle valve, or clogged inlet screen in the

carburetor.

l

Damaged, loose ground, or improper

wiring.

l

Worn needle and seat assembly in

l

Replace worn needle and seat assembly

carburetor.

in carburetor.

l

Wrong pump application: that is, standard

pressure pump for low pressure

application.

l

Air leak on inlet side of pump due to holes

in fuel line or loose fittings.

l

Fuel line fitting connections at pump are

loose or dirty.

ACTION

I

l

Clean or replace filter.

l

Repair fuel line or remove restriction.

l

Repair or replace as needed.

l

Inspect all mounting or wiring.

l

Change to a low pressure pump

l

Replace fuel line, and tighten fittings (apply

a sealer, if necessary).

pump-

Loading...

Loading...