03-6 Auxiliary Systems

03-6

DISTRIBUTORLESS IGNITION SYSTEM DIAGNOSING AND TESTING

Diagnosis Equipment

To accurately diagnose DIS, certain diagnostic

equipment and tools are required. In addition, the

suggested diagnostic equipment may make the job

easier and more convenient.

Prior to diagnosing DIS, obtain the following test

equipment or equivalent:

l

Spark tester, neon bulb type (Champion CT-436)

There is no need to disconnect a plug wire; just

place this spark tester on a spark plug wire to

determine if spark is being provided to the plug.

This is especially useful for those hard-to-reach

plug wires.

l

Spark tester, gap type (special service tool

081 P-6666-A)

Connect this gap type spark tester between any

spark plug wire and engine ground to instantly

determine if spark is being provided to the plug. A

spark plug with a broken side electrode is not

sufficient to check for spark and may lead to

incorrect results.

l

Volt-ohmmeter (Rotunda 014-00575)

A volt-ohmmeter is essential for gathering system

operating data during diagnosis, testing, and

engine servicing procedures. This digital volt-

ohmmeter (DVOM) can also be used for general

purpose electrical troubleshooting on conventional

starting and charging systems.

l

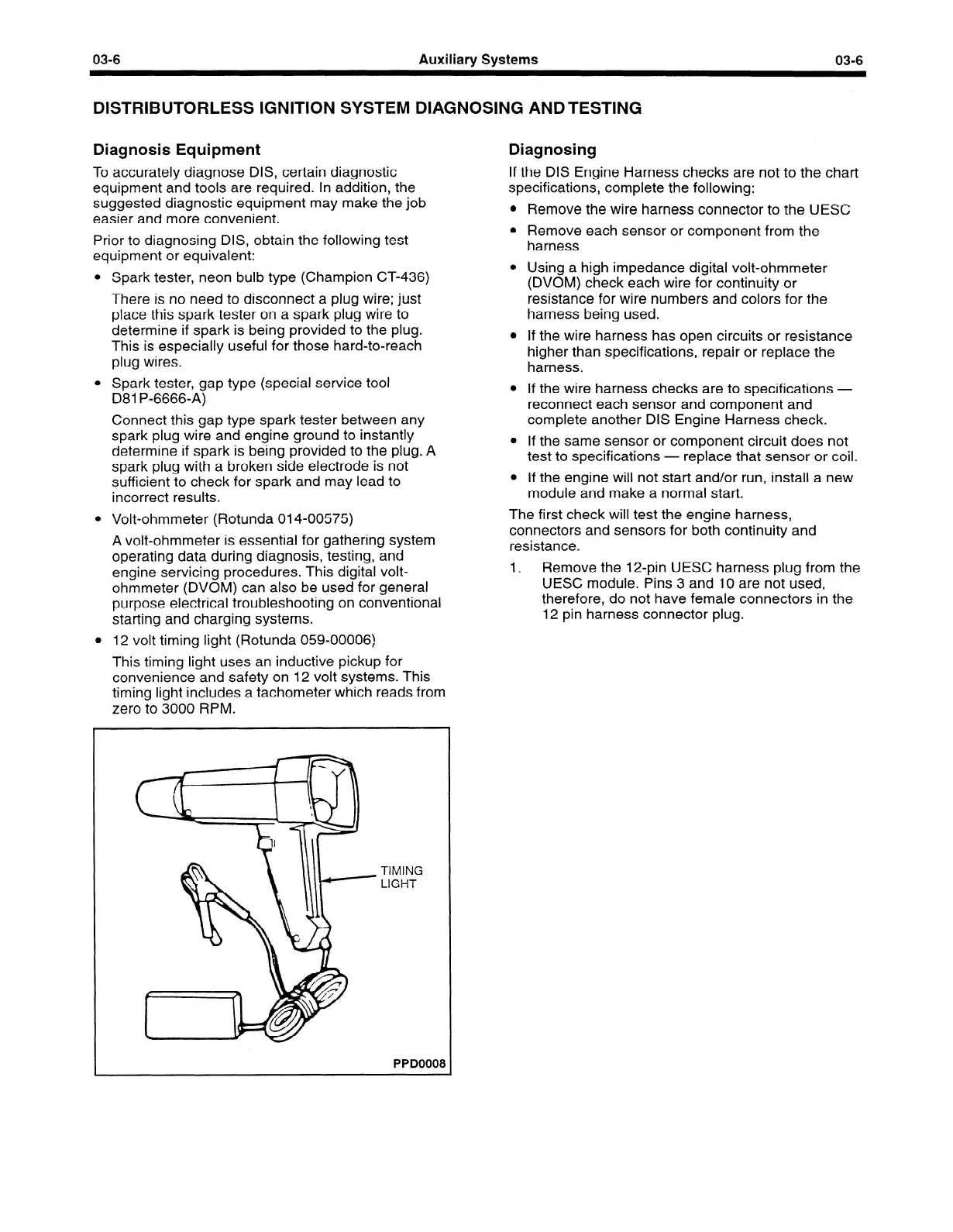

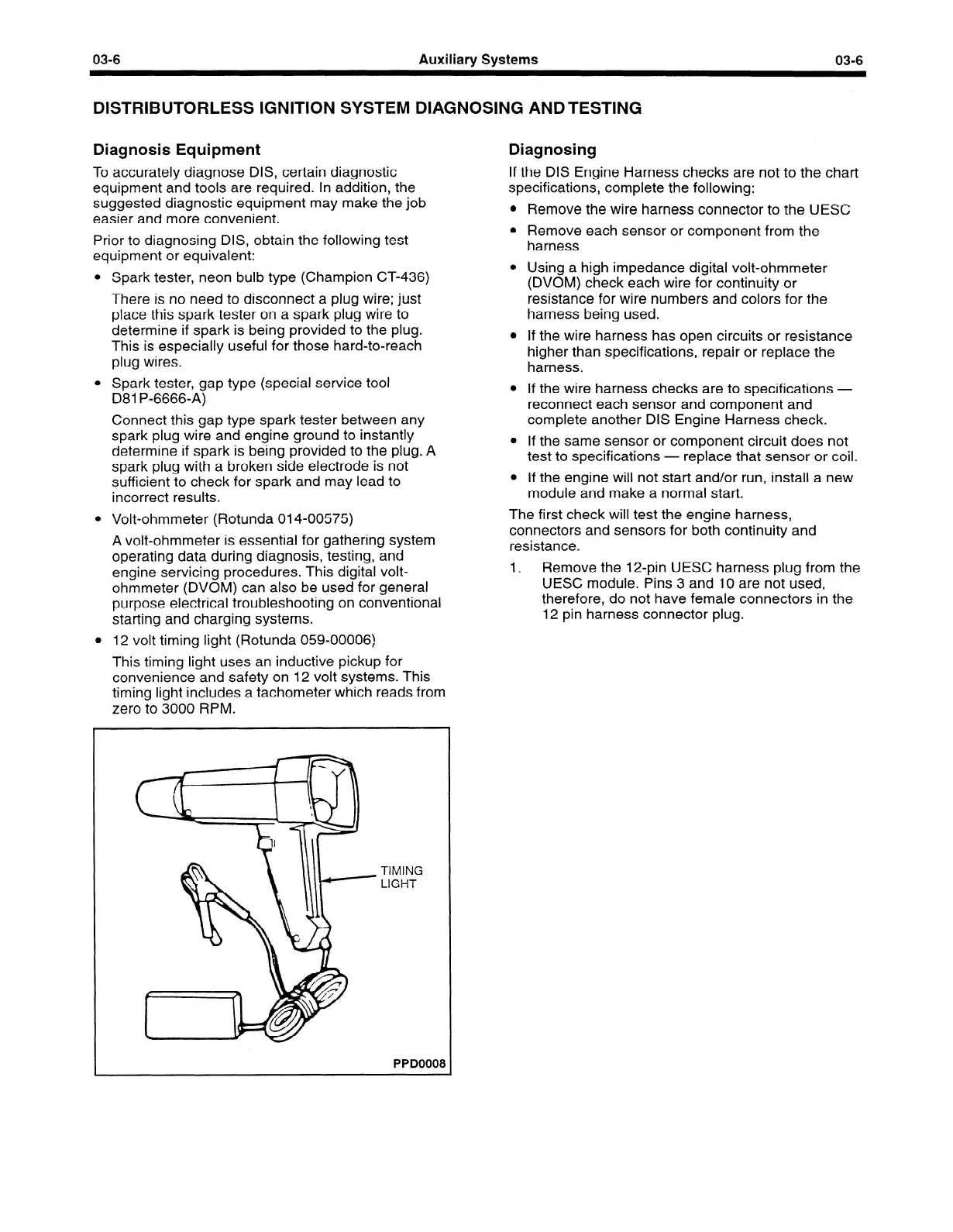

12 volt timing light (Rotunda 059-00006)

This timing light uses an inductive pickup for

convenience and safety on 12 volt systems. This

timing light includes a tachometer which reads from

zero to 3000 RPM.

Diagnosing

If the DIS Engine Harness checks are not to the chart

specifications, complete the following:

l

Remove the wire harness connector to the UESC

l

Remove each sensor or component from the

harness

l

Using a high impedance digital volt-ohmmeter

(DVOM) check each wire for continuity or

resistance for wire numbers and colors for the

harness being used.

l

If the wire harness has open circuitsor resistance

higher than specifications, repair or replace the

harness.

l

If the wire harness checks are to specifications -

reconnect each sensor and component and

complete another DIS Engine Harness check.

l

If the same sensor or component circuit does not

test to specifications - replace that sensor or coil.

l

If the engine will not start and/or run, install a new

module and make a normal start.

The first check will test the engine harness,

connectors and sensors for both continuity and

resistance.

1.

Remove the 12,pin UESC harness plug from the

UESC module. Pins 3 and 10 are not used,

therefore, do not have female connectors in the

12 pin harness connector plug.

TIMING

LIGHT

Loading...

Loading...