01-17 Engine Service

01-17

SERVICE PROCEDURES (Continued)

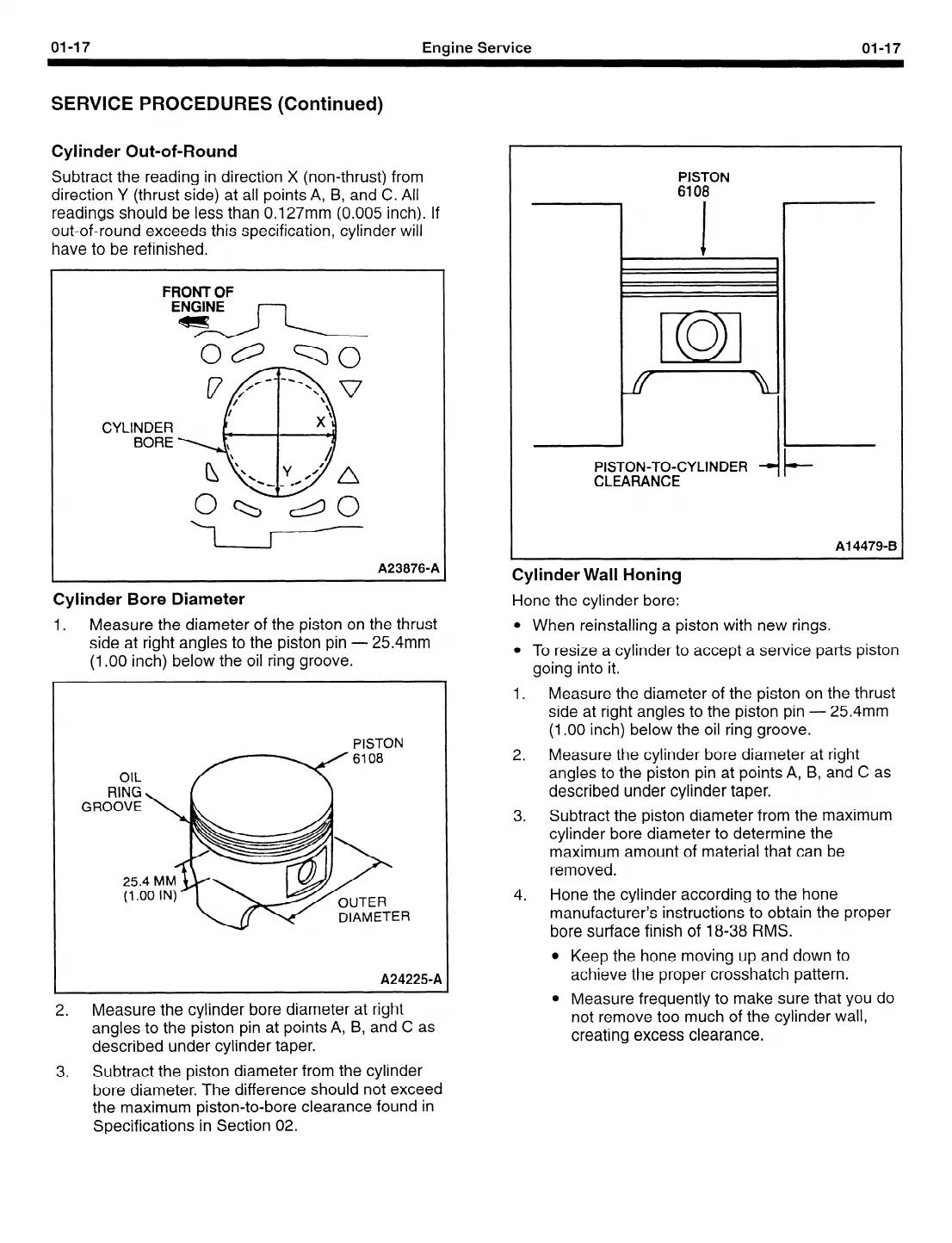

Cylinder Out-of-Round

Subtract the reading in direction X (non-thrust) from

direction Y (thrust side) at all points A, B, and C. All

readings should be less than 0.127mm (0.005 inch). If

out-of-round exceeds this specification, cylinder will

have to be refinished.

CYLI

FRONT

OF

Egz

NDER

BORE

A23876-A

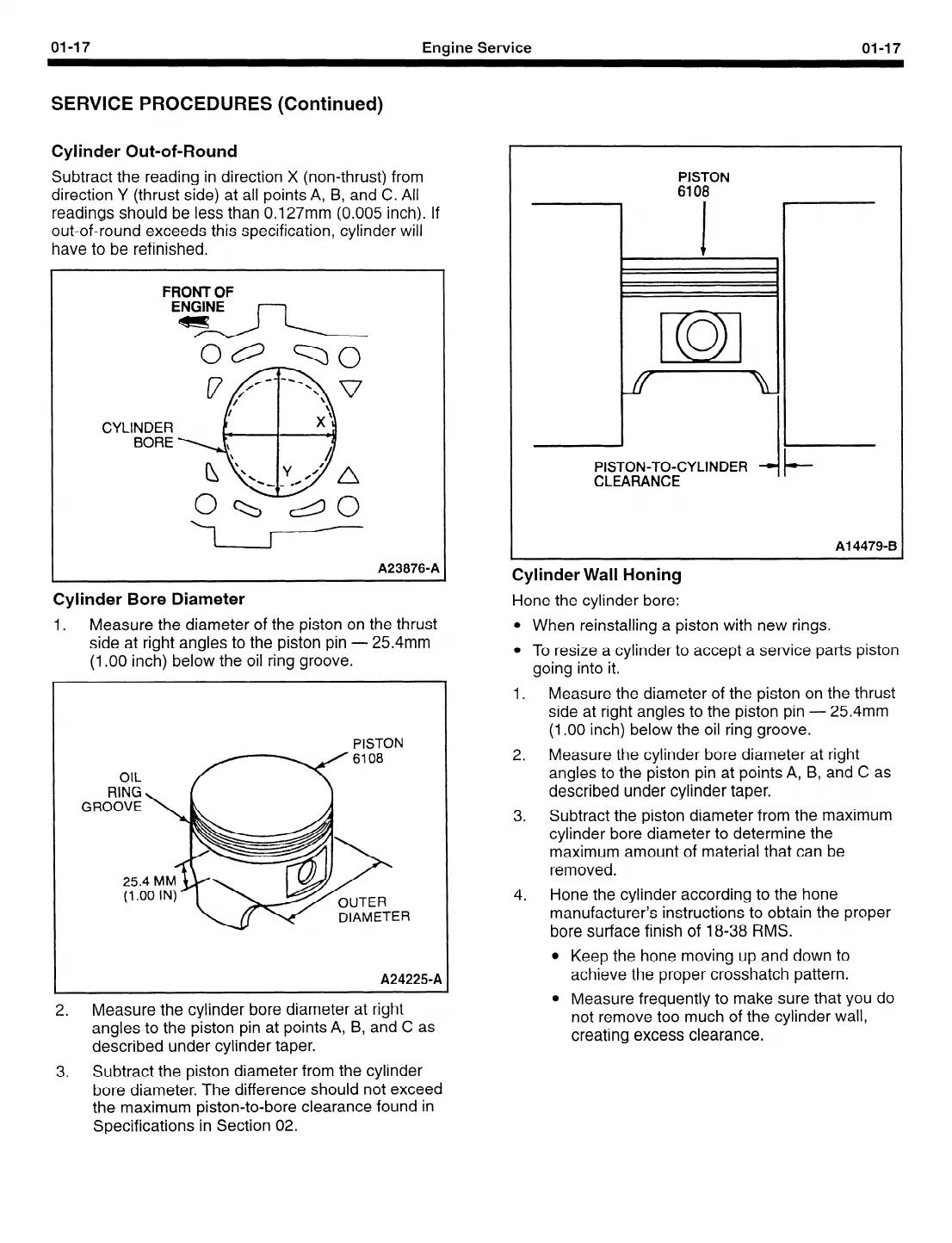

Cylinder Bore Diameter

1.

Measure the diameter of the piston on the thrust

side at right angles to the piston pin - 254mm

(1 .OO inch) below the oil ring groove.

GR

PISTON

:I3

A24225-A

2. Measure the cylinder bore diameter at right

angles to the piston pin at points A, B, and C as

described under cylinder taper.

3.

Subtract the piston diameter from the cylinder

bore diameter. The difference should not exceed

the maximum piston-to-bore clearance found in

Specifications in Section 02.

PISTON

6108

PISTON-TO-CYLINDER 1 f--

CLEARANCE

Al 4479-B

Cylinder Wall Honing

Hone the cylinder bore:

l

When reinstalling a piston with new rings.

l

To resize a cylinder to accept a service parts piston

going into it.

1. Measure the diameter of the piston on the thrust

side at right angles to the piston pin - 254mm

(1 .OO inch) below the oil ring groove.

2.

Measure the cylinder bore diameter at right

angles to the piston pin at points A, B, and C as

described under cylinder taper.

3.

Subtract the piston diameter from the maximum

cylinder bore diameter to determine the

maximum amount of material that can be

removed.

4.

Hone the cylinder according to the hone

manufacturer’s instructions to obtain the proper

bore surface finish of 18-38 RMS.

l

Keep the hone moving up and down to

achieve the proper crosshatch pattern.

l

Measure frequently to make sure that you do

not remove too much of the cylinder wall,

creating excess clearance.

Loading...

Loading...