02-47

Engine Service, 2.3L

02-47

2.3L ENGINE SERVICE (Continued)

Installation

CAUTION: Lubricate parts with Motorcraft Super

Premium Motor Oil XO+W30=QSP, or equivalent,

meeting Ford specification ESE-M2C153-E during

assembly to prevent a dry start and engine

damage.

1.

if removed, install upper crankshaft bearings. If

reusing bearings, reinstall each bearing in the

same place from which it was removed.

2. Install crankshaft.

3. If removed, install bearings in main bearing caps.

If reusing bearings, install bearing in same place

from which it was removed.

4. Apply Plastigage@ to crankshaft bearing journals.

5.

Install main bearing caps and bolts. Alternately

tighten bolts to 68-81 Nom (50-60 lb-ft). Retighten

to 108-122 Nom (79-90 lb-ft).

6.

Remove caps. Check Plastigage@ for bearing

clearance using chart on package. If OK, go on to

next step. If not, correct clearance.

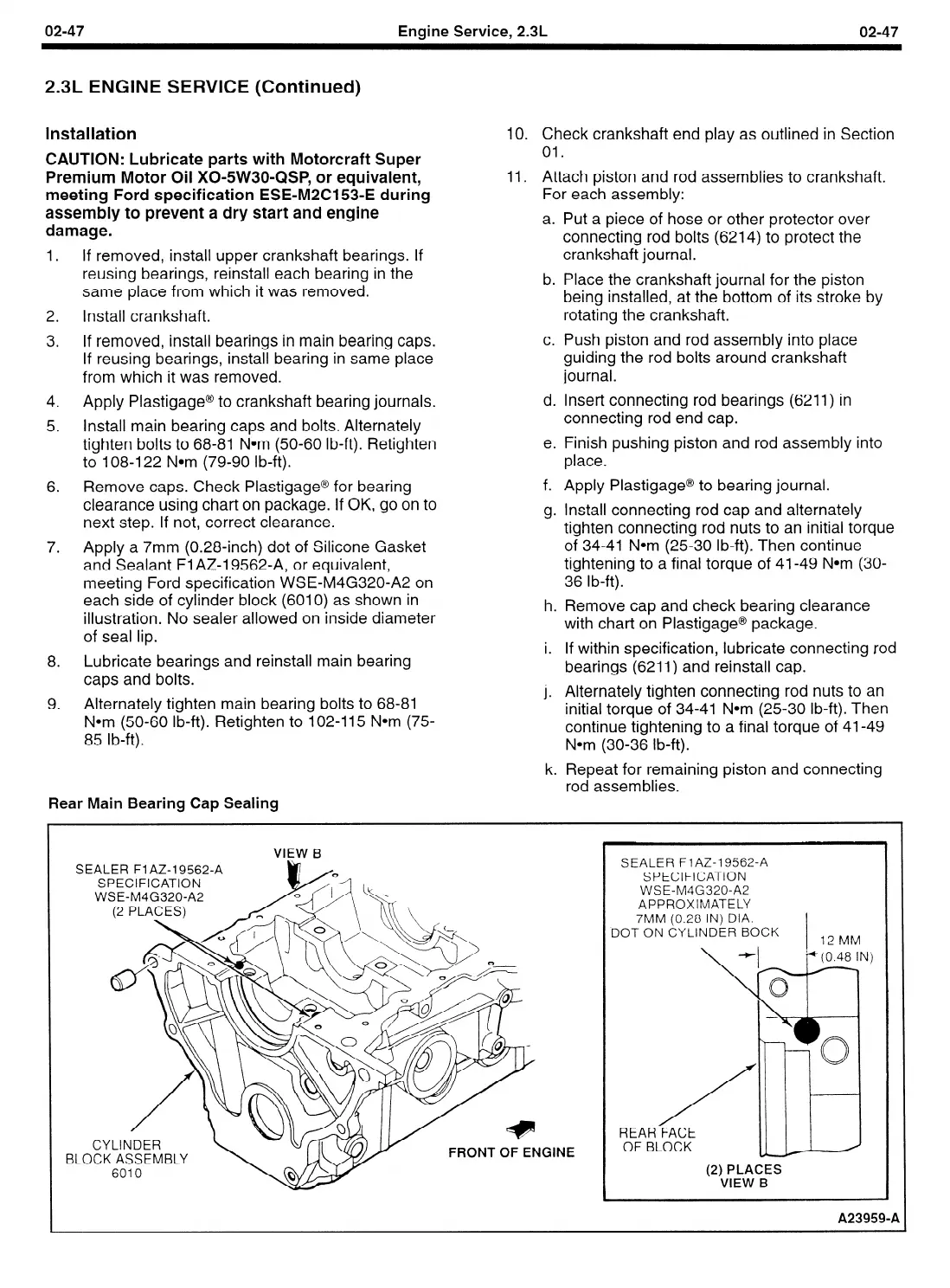

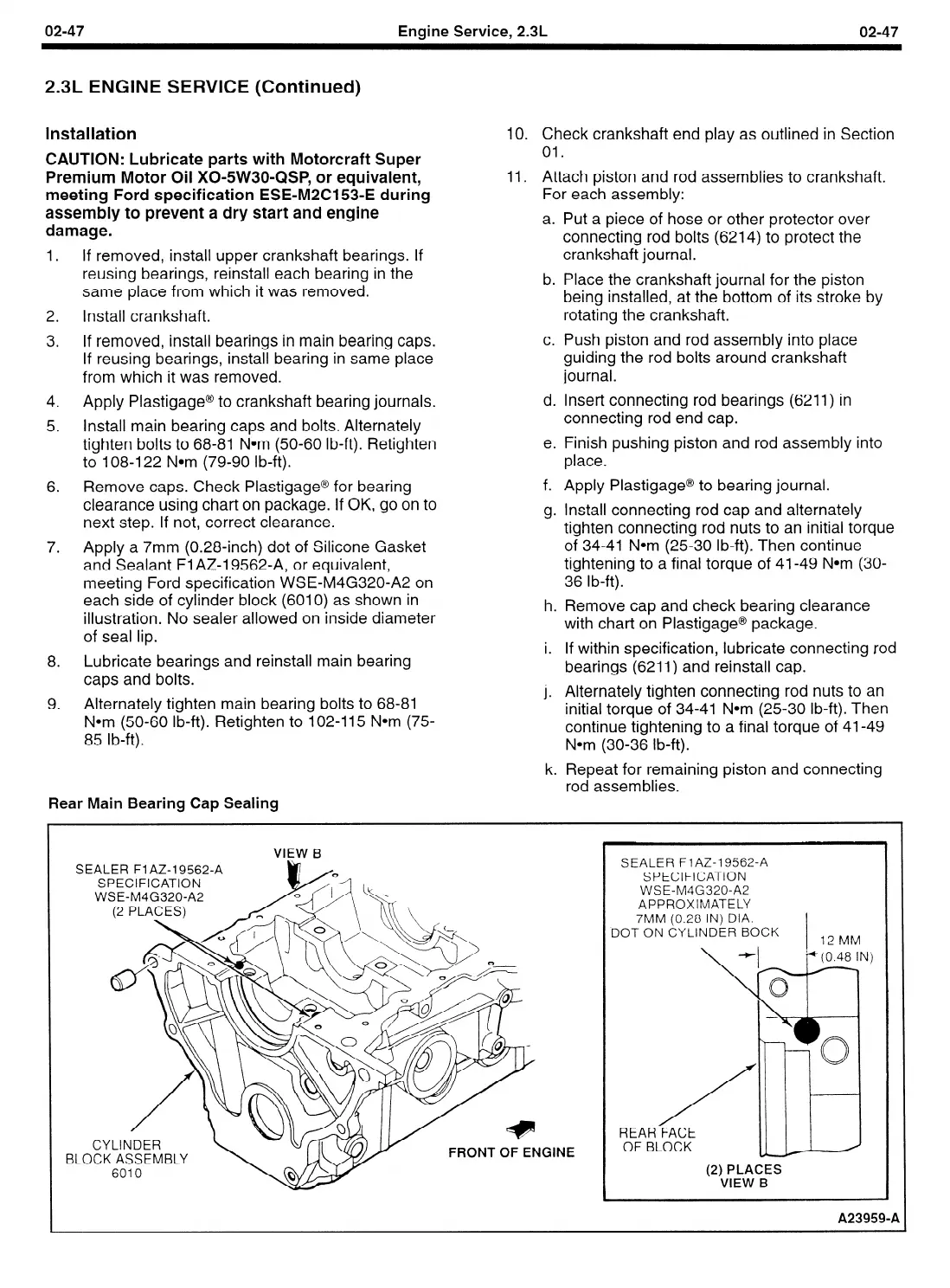

7. Apply a 7mm (0.28-inch) dot of Silicone Gasket

and Sealant Fl AZ-l 9562-A, or equivalent,

meeting Ford specification WSE-M4G320-A2 on

each side of cylinder block (6010) as shown in

illustration. No sealer allowed on inside diameter

of seal lip.

8. Lubricate bearings and reinstall main bearing

caps and bolts.

9. Alternately tighten main bearing bolts to 68-81

Nom (50-60 lb-ft). Retighten to 102-115 Nom (75-

85 lb-ft).

Rear Main Bearing Cap Sealing

10. Check crankshaft end play as outlined in Section

01.

11.

Attach piston and rod assemblies to crankshaft.

For each assembly:

a. Put a piece of hose or other protector over

connecting rod bolts (6214) to protect the

crankshaft journal.

b. Place the crankshaft journal for the piston

being installed, at the bottom of its stroke by

rotating the crankshaft.

c. Push piston and rod assembly into place

guiding the rod bolts around crankshaft

journal.

d. Insert connecting rod bearings (6211) in

connecting rod end cap.

e. Finish pushing piston and rod assembly into

place.

f. Apply Plastigage@ to bearing journal.

g. Install connecting rod cap and alternately

tighten connecting rod nuts to an initial torque

of 34-41 Nom (25-30 lb-ft). Then continue

tightening to a final torque of 41-49 Nom (30-

36 lb-ft).

h. Remove cap and check bearing clearance

with chart on Plastigage@ package.

i. If within specification, lubricate connecting rod

bearings (6211) and reinstall cap.

j. Alternately tighten connecting rod nuts to an

initial torque of 34-41 Nom (25-30 lb-ft). Then

continue tightening to a final torque of 41-49

Nom (30-36 lb-ft).

k. Repeat for remaining piston and connecting

rod assemblies.

VIEW B

SE

CYLINDER

ILOCK ASSEMBLY

FRONT OF ENGI

NE

SEALER FlAZ-19562-A

SPECIFICATION

WSE-M4G320-A2

APPROXIMATELY

7MM (0.28 IN) DIA.

DOT ON CYLINDER

BOCK

12

MM

REAR FACE

OF BLOCK

(2) PLACES

VIEW B

A23959-A

Loading...

Loading...