03-51

Auxiliary Systems

03-51

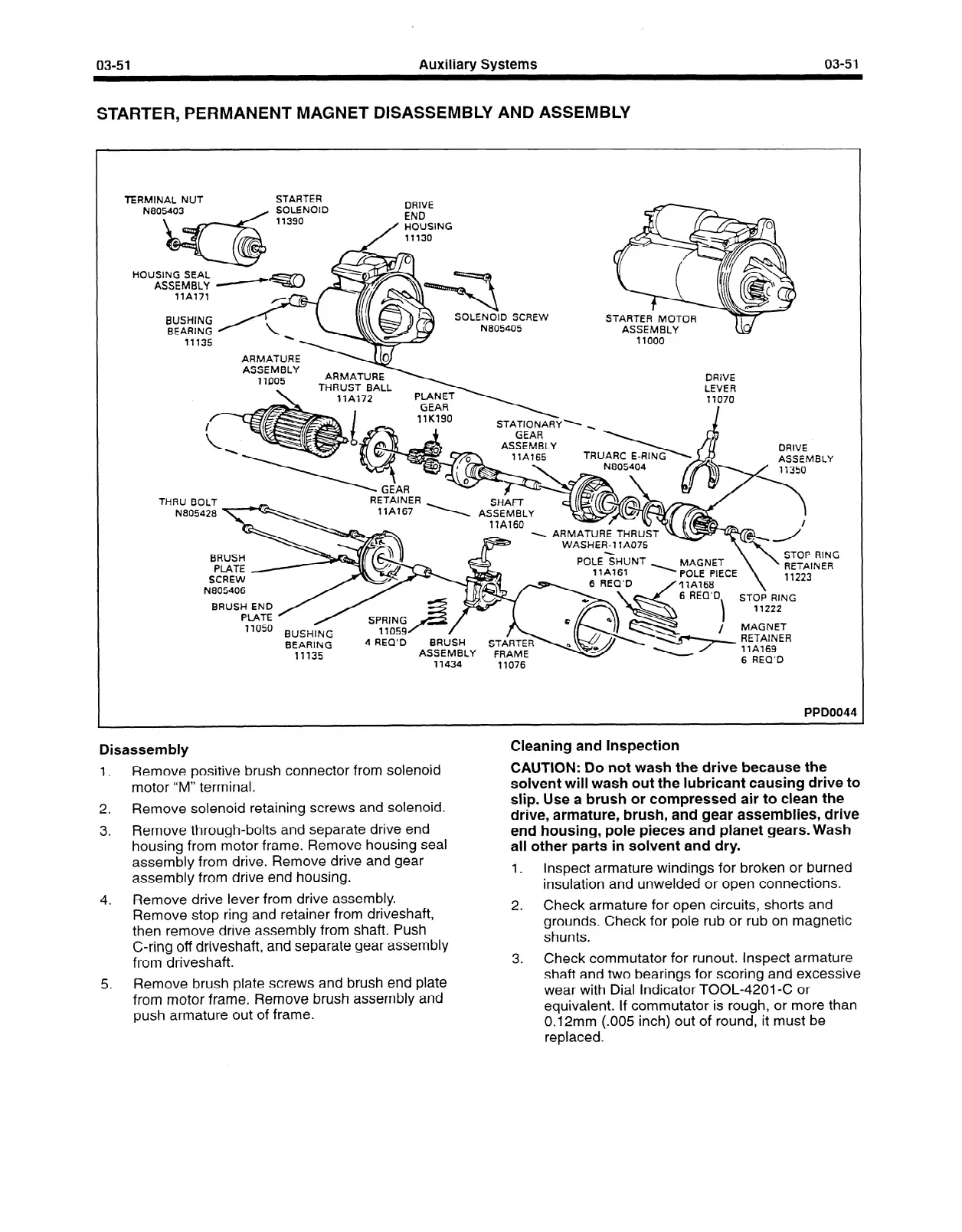

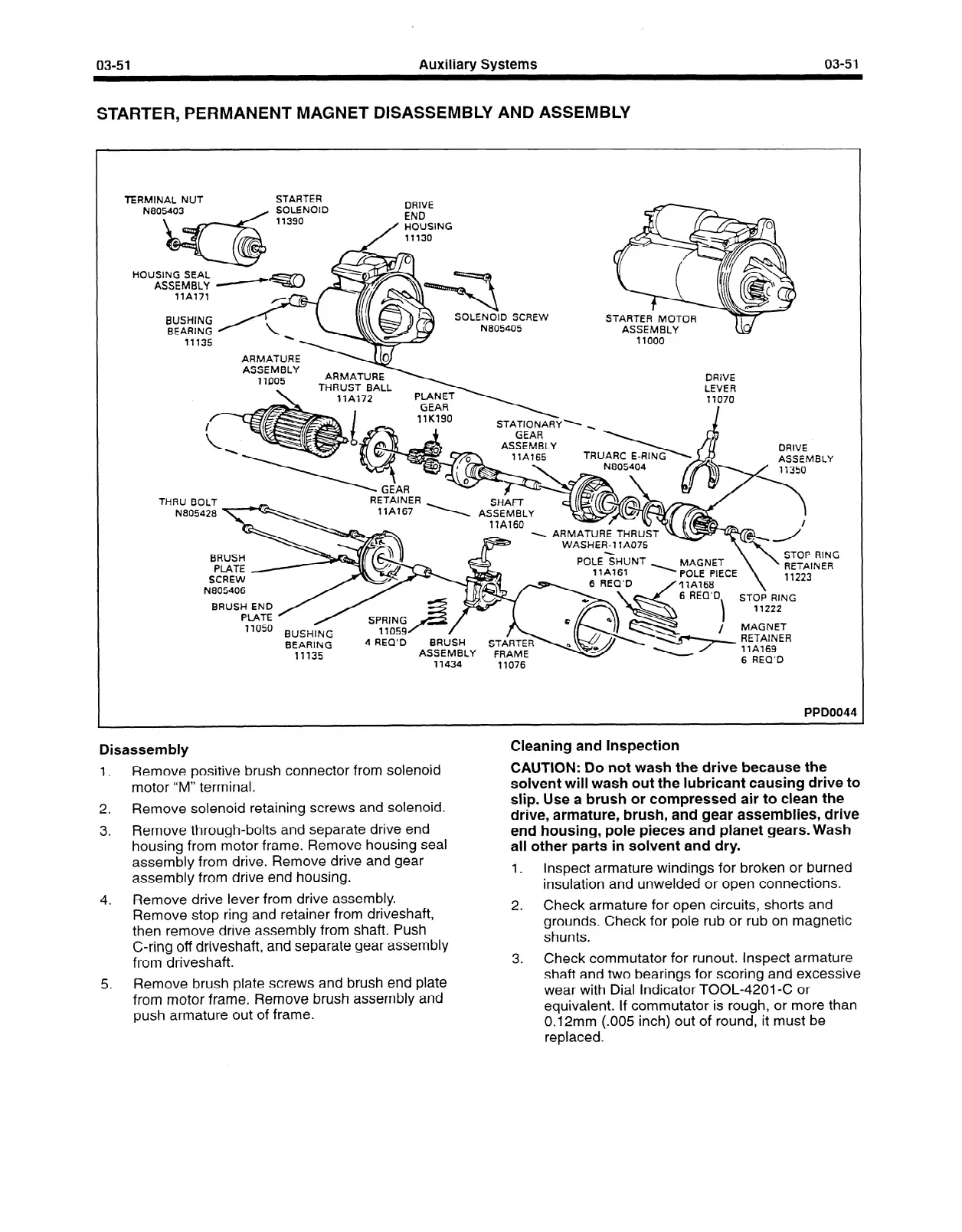

STARTER, PERMANENT MAGNET DISASSEMBLY AND ASSEMBLY

TERMINAL NUT

STARTER

N805403

/ SOLENOID

11390

DRIVE

END

/

HOUSING

11130

HOUSING SEAL

--

WtJcJk

ASSEMBLY -v

llA771

STARTEff’ MOTOR

ASSEMBLY

BUSHING /!

BEARING y \

ARMA-T

ASSEM

77DC

DRIVE

LEVER

GEAR

17K190

STATfONARY. \

GEAR

ASSEMBLY _

DRIVE

ASSEMBLY

TRUARC

RETAINER .

17A767

THRU BOLT

SHAm

\ ASSEMBLY

17A160

N805428 \

STOP

RING

POLE<HUNT -

- - - -----

MAGNET \

b _A. a -.c-c

’ RETAINER

BRUS

PLATE

SCREW

N805406

IwLt rltLt

\

71223

17A168

6 REQ’D

I

STOP RING

11222

BRUSH

END

Pl

ATE

7

7050

i

MAGNET

BUSHING

BEARING

11135

4 REQ’D

BRUSH

STiRTEd

ASSEMBLY

FRAME

71434

11076

PPDOO 44

Disassembly

1.

Remove positive brush connector from solenoid

motor “M” terminal.

2. Remove solenoid retaining screws and solenoid.

3. Remove through-bolts and separate drive end

housing from motor frame. Remove housing seal

assembly from drive. Remove drive and gear

assembly from drive end housing.

4. Remove drive lever from drive assembly.

Remove stop ring and retainer from driveshaft,

then remove drive assembly from shaft. Push

C-ring off driveshaft, and separate gear assembly

from driveshaft.

Cleaning and Inspection

CAUTION: Do not wash the drive because the

solvent will wash out the lubricant causing drive to

slip. Use a brush or compressed air to clean the

drive, armature, brush, and gear assemblies, drive

end housing, pole pieces and planet gears. Wash

all other parts in solvent and dry.

1.

Inspect armature windings for broken or burned

insulation and unwelded or open connections.

2.

Check armature for open circuits, shorts and

grounds. Check for pole rub or rub on magnetic

shunts.

3.

Check commutator for runout. Inspect armature

shaft and two bearings for scoring and excessive

wear with Dial Indicator TOOL-4201-C or

equivalent. If commutator is rough, or more than

0.12mm (.005 inch) out of round, it must be

replaced.

5. Remove brush plate screws and brush end plate

from motor frame. Remove brush assembly and

push armature out of frame.

Loading...

Loading...