01-16

Engine Service

01-16

SERVICE PROCEDURES (Continued)

Cylinder Walls, Refinishing

Cleaning

If the entire engine has NOT been disassembled,

clean the individual cylinder bore(s) with a cloth

soaked in solvent. Dry with a clean, lint-free cloth.

If the entire engine HAS been disassembled, refer to

Cylinder Block Cleaning in this section.

After any cylinder bore service operation, such as

honing or deglazing, clean the bore(s) with soap or

detergent and water. Then thoroughly rinse the bore(s)

with clean water to remove the soap or detergent, and

wipe the bore(s) dry with a clean lint-free cloth. Finally,

wipe the bore(s) with a clean cloth dipped in

X0-1 OW30-QSP or -DSP, or equivalent, motor oil

meeting Ford specification ESE-M2C153-E.

Inspection

Before removing the piston (6108):

1. Check the amount of ridge at the top of the bore.

A thick ridge is a sign of considerable wear.

2. Look for signs of coolant in the bore, especially

rust on the bore surface indicating possible

leaking head gasket or a crack in the cylinder

bore.

3. Check the top of the piston for possible oversize.

If oversize pistons have been installed, the

oversize will be stamped in the top of the piston

(6110).

After the piston is removed and the bore cleaned:

4.

5.

6.

Look for scoring. These are parallel gouges

usually on the piston thrust side, that is, at right

angles to the piston pin. If scored, the cylinder will

have to be refinished.

Look for cracks. If unsure about a crack, tiny

cracks may be detected by coating the bore with

a mixture of 25 percent kerosene and 75 percent

light engine oil. Wipe the bore dry and

immediately apply a coating of zinc oxide

dissolved in wood alcohol. Do not use rubbing

alcohol as a substitute. If cracks are present, the

coating will become discolored at the damaged

area. Replace the cylinder block if it is cracked.

Magnafluxing may also be used.

Check for cylinder wall glazing. When refinished,

the cylinder bore is given a slightly rough finish

with a cylinder hone to help seat the new piston

rings. This finish is worn away as the rings and

cylinder bore “mate” and the bore becomes

glassy smooth. If the engine has been run

enough for this to have happened, the cylinder

will at least have to be honed to seat the new

rings on the piston. New rings should be installed

when the piston is removed and reinstalled

because piston rings are given a special finish by

the factory to help them wear-in and seat. In

seating, the special finish is worn off. Reusing

piston rings will result in high oil consumption.

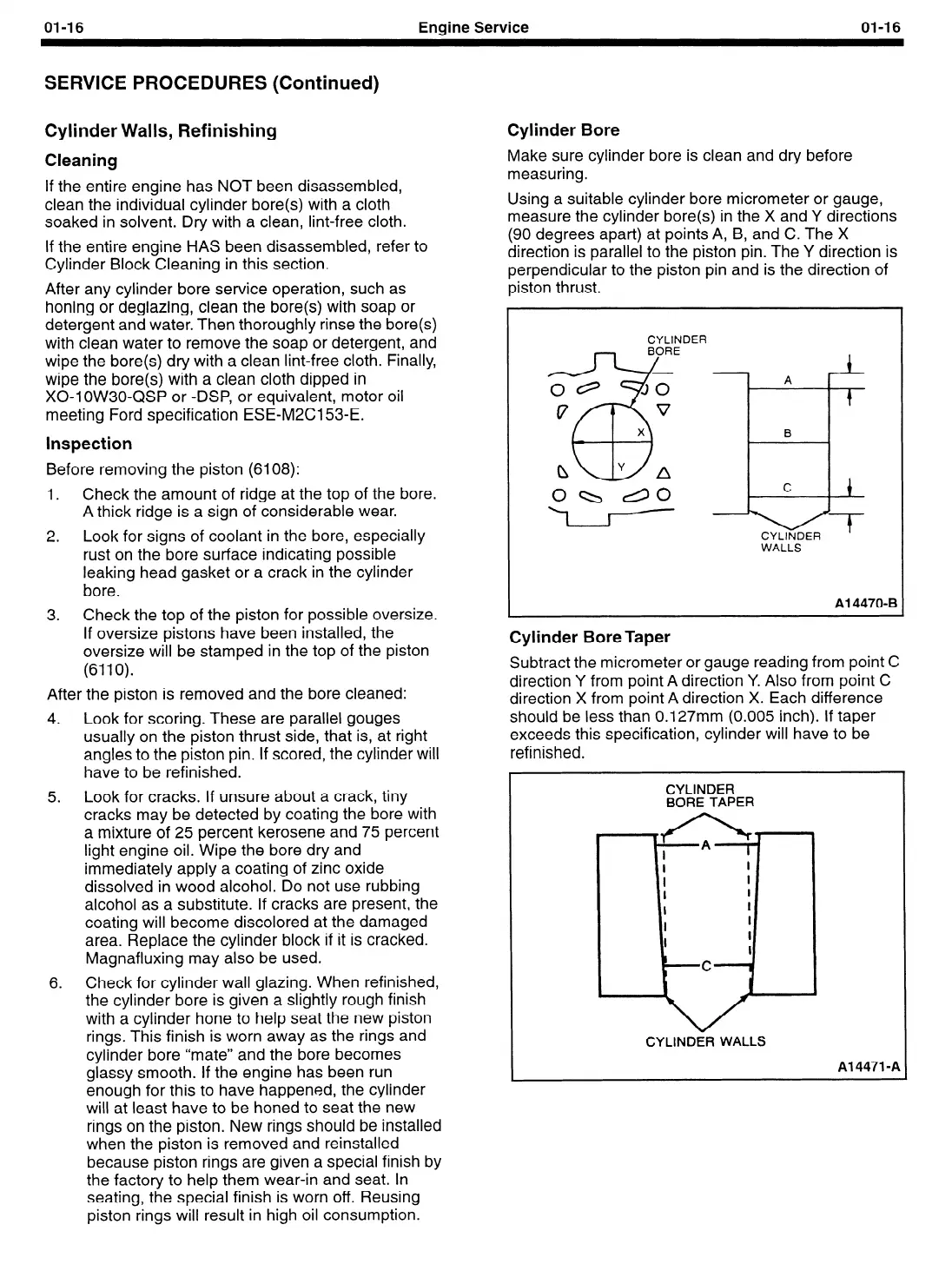

Cylinder Bore

Make sure cylinder bore is clean and dry before

measuring.

Using a suitable cylinder bore micrometer or gauge,

measure the cylinder bore(s) in the X and Y directions

(90 degrees apart) at points A, B, and C. The X

direction is parallel to the piston pin. The Y direction is

perpendicular to the piston pin and is the direction of

piston thrust.

CYLINDER

1

.

.

A

t

B

CYLINDER

WALLS

Al 4470-B

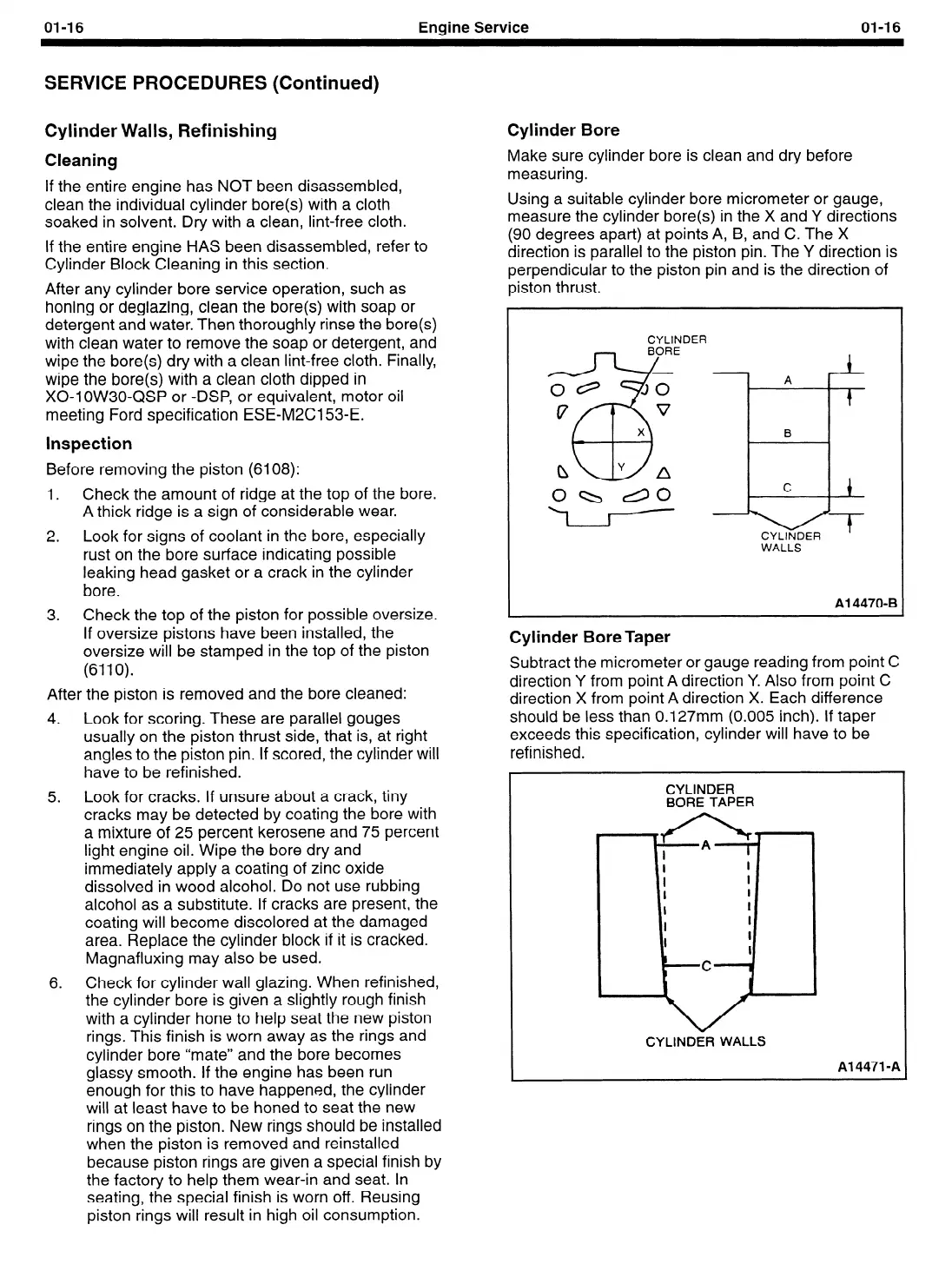

Cylinder Bore Taper

Subtract the micrometer or gauge reading from point C

direction Y from point A direction Y. Also from point C

direction X from point A direction X. Each difference

should be less than 0.127mm (0.005 inch). If taper

exceeds this specification, cylinder will have to be

refinished.

CYLINDER

BORE TAPER

CYLINDER WALLS

Al 4471 -A

Loading...

Loading...