IS620P User Manual Chapter 6 Troubleshooting

- 133 -

17. Er.234: Runaway

Cause:

•

The torque reference direction is reversed to the speed feedback direction in the torque

control mode.

•

The speed feedback is reversed to the speed reference direction in the position or speed

control mode.

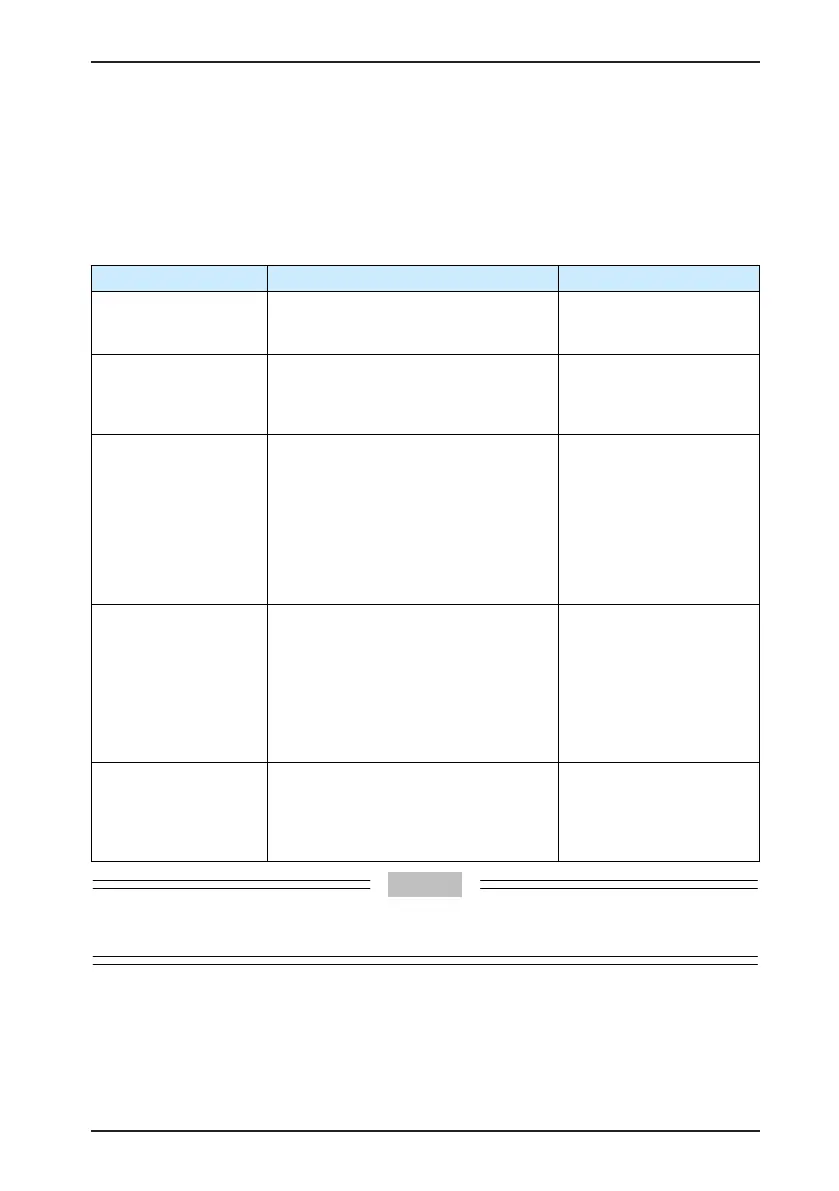

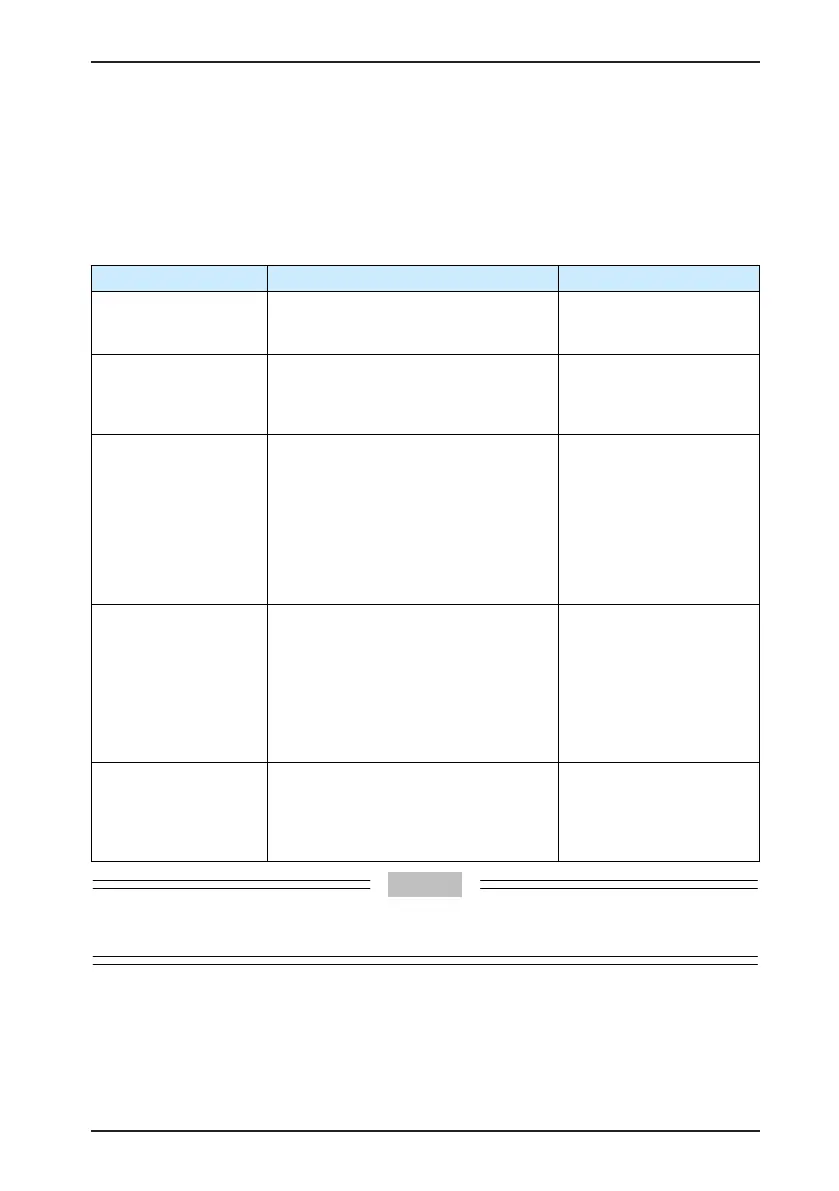

Cause Conrming Method Corrective Action

1. The UVW phase

sequence is incorrect.

•

Check whether the UVW phase

sequence on the servo drive side is

consistent with that on the motor side.

Connect the UVW cables

according to the correct

phase sequence.

2. The motor rotor

initial phase detection

is incorrect due to

interference at power-on.

•

The UVW phase sequence is correct.

But Er.234 is reported once the servo

drive is enabled.

Re-power on the servo

system.

3. The encoder type is

set incorrectly or the

wiring is incorrect.

•

Check that the equipments you are

using are the IS620P series servo

drive and 20-bit servo motor (-U2***) of

Inovance based on the nameplate of

the servo drive and motor.

Replace the unmatched

servo drive or motor. If you

use the IS620P series servo

drive and 20-bit servo motor

(-U2***) of Inovance, ensure

that H00-00 = 14000. Re-

conrm the motor model,

encoder type and encoder

wiring.

The cable wiring is

incorrect. The cable is

aging, corrosive or is

connected loosely.

•

Check whether the cable you use is

standard conguration of Inovance and

whether the cable is aged, corroded or

loose.

•

Set the servo enabled signal to OFF

and rotate the motor shaft manually.

Check whether H0B-10 (rotation angle)

changes as the motor rotates.

Re-weld, fasten or replace

the encoder cable.

5. On the working

condition of controlling a

vertical shaft, the gravity

load is too large.

•

Check whether the load of the vertical

shaft is too large. Adjust the braking

parameters H02-09 to H02-12 and then

see whether the fault is eliminated.

Reduce the load of the

vertical shaft, improve the

rigidity or shield this fault

in the prerequisite of not

affecting the safety and use.

On the working condition of controlling a vertical shaft or one motor dragging the other, set H0A-12 =

0 to shield the runaway fault.

Loading...

Loading...