Chapter 4 Running and Commissioning IS620P User Manual

- 94 -

b. Torque reference selection

In the torque control mode, ve methods of obtaining torque references are available, and you

can select one in H07-02.

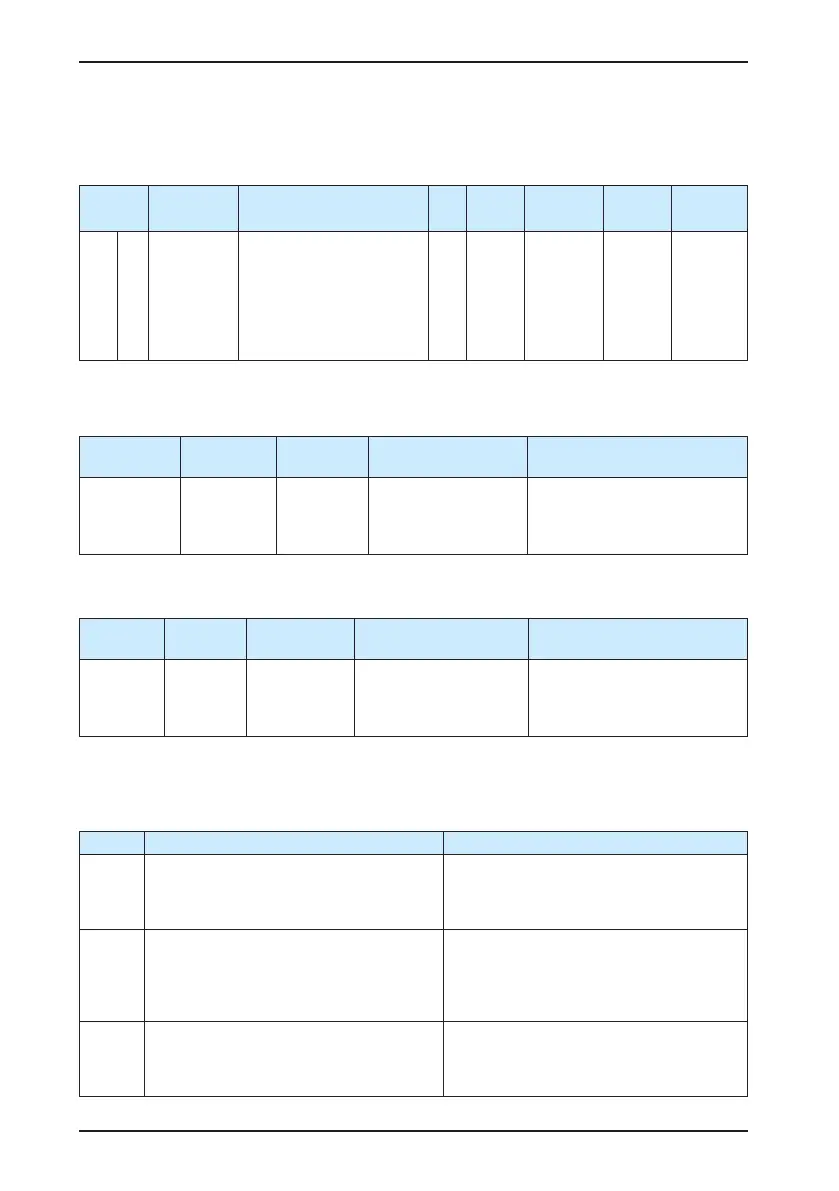

Function

Code

Parameter

Name

Setting Range Unit Default

Effective

Time

Property

Control

Mode

H07 02

Torque

reference

source

0: Main torque reference A

source

1: Auxiliary torque reference

B source

2: A+B

3: A/B switchover

4: Communication setting

- 0 Immediate At stop T

c. Torque reference direction switchover

Set the function FunIN.25 to switch over the torque reference direction by a DI.

Function No.

Function

Name

Description Setting Remarks

FunIN.25 TOQDirSel

Torque

reference

direction

Valid: Forward

direction

Invalid: Reverse

direction

It is recommended that the

logic of the corresponding

terminal be set to level valid.

When H07-02 = 3, you need to allocate a DI with the A/B switchover function to determine

whether A reference input or B reference input is active currently.

Function

No.

Function

Name

Description Setting Remarks

FunIN.4 CMD-SEL

Main/Auxiliary

reference

switchover

Valid: Current running

reference being A

Invalid: Current running

reference being B

It is recommended that the

logic of the corresponding

terminal be set to level valid.

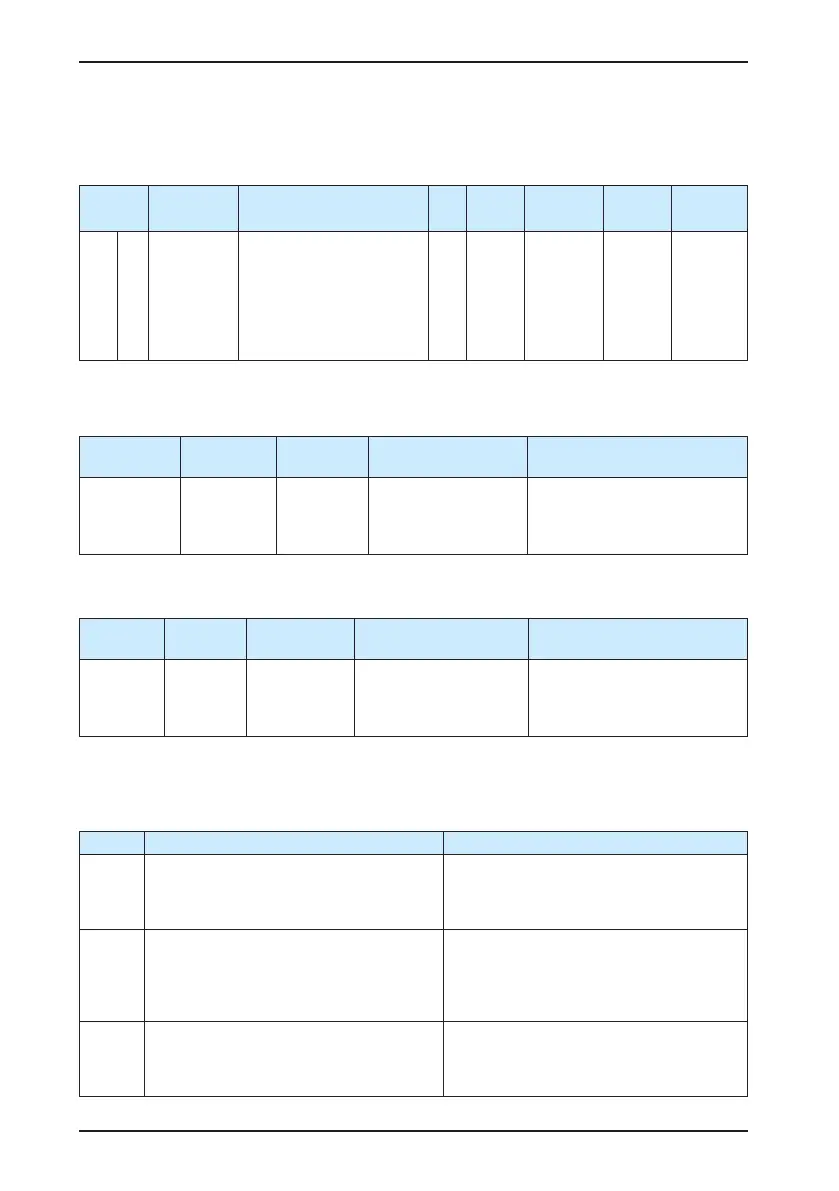

The following table takes AI1 as an example to describe the analog setting of the torque

reference.

Table 4-5 Analog setting of torque reference

Step Operation Remarks

1

Set H07-02 (Torque reference selection)

to 1 (Auxiliary torque reference B source)

and H07-01 (Auxiliary torque reference B

source) to 1 (AI1).

Set the torque reference source in the

torque control mode.

2

Set related parameters of AI1.

a. Zero drift correction (set in H03-54 or

auto correction in H0D-10)

b. AI1 offset (H03-50)

c. AI1 dead zone (H03-53)

Adjust AI2 sampling by setting the zero drift,

offset, and dead zone.

3

Set H03-81 (Torque corresponding to 10 V)

to 3 times of the rated torque.

Set the maximum torque (value of H03-81)

corresponding to +10 V.

Set the minimum torque (negative value of

H03-81) corresponding to -10 V.

Loading...

Loading...