2C-4 - ELECTRICAL 90-826148R2 MARCH 1997

Tiller Handle Model with

Mechanical Spark Advance

(S/N-0G590000 & Above)

1. Check all electrical connections to ensure they

are tight and secure (including battery connec-

tions on electric start models).

2. With engine off and gear shift in neutralposition,

loosen cam follower screw.

3. Backoffidlespeedscrewuntilthethrottleshutter

positioner does not touch the taper of idle speed

screw. (Throttle plate closed).

4. Loosen throttle cable jam nuts.

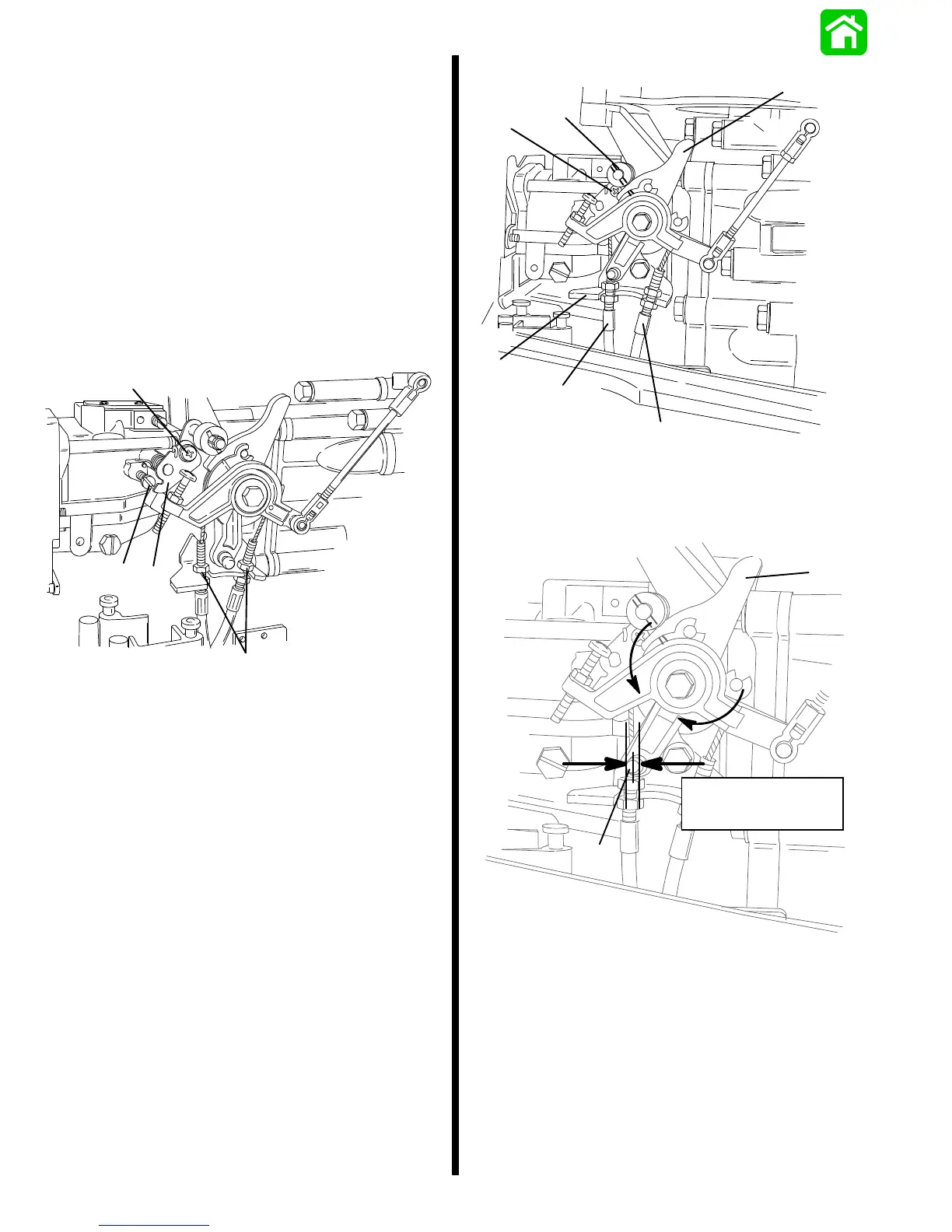

55896

a

b

c

d

a - Idle Speed Screw

b - Cam Follower Screw

c - Throttle Shutter Positioner

d - Jam Nuts

5. With throttle at idle position, place cam follower

roller against throttle cam. Center the roller with

raisedmarkonthrottlecambyadjustingtheposi-

tion of throttle cable sleeves in the mounting

bracket on tiller handle models or throttle linkrod

on remote control models.

NOTE: When positioning throttlecables, a minimum

of 1/16 in. (1.59 mm) to a maximum of 1/8 in. (3.18

mm)slackmust beallowed to preventthrottlecables

from binding. (Rock throttle cam side to side and

measure the amount of throttle cam travel at link rod

ball.

6. Tighten throttle cable jam nuts.

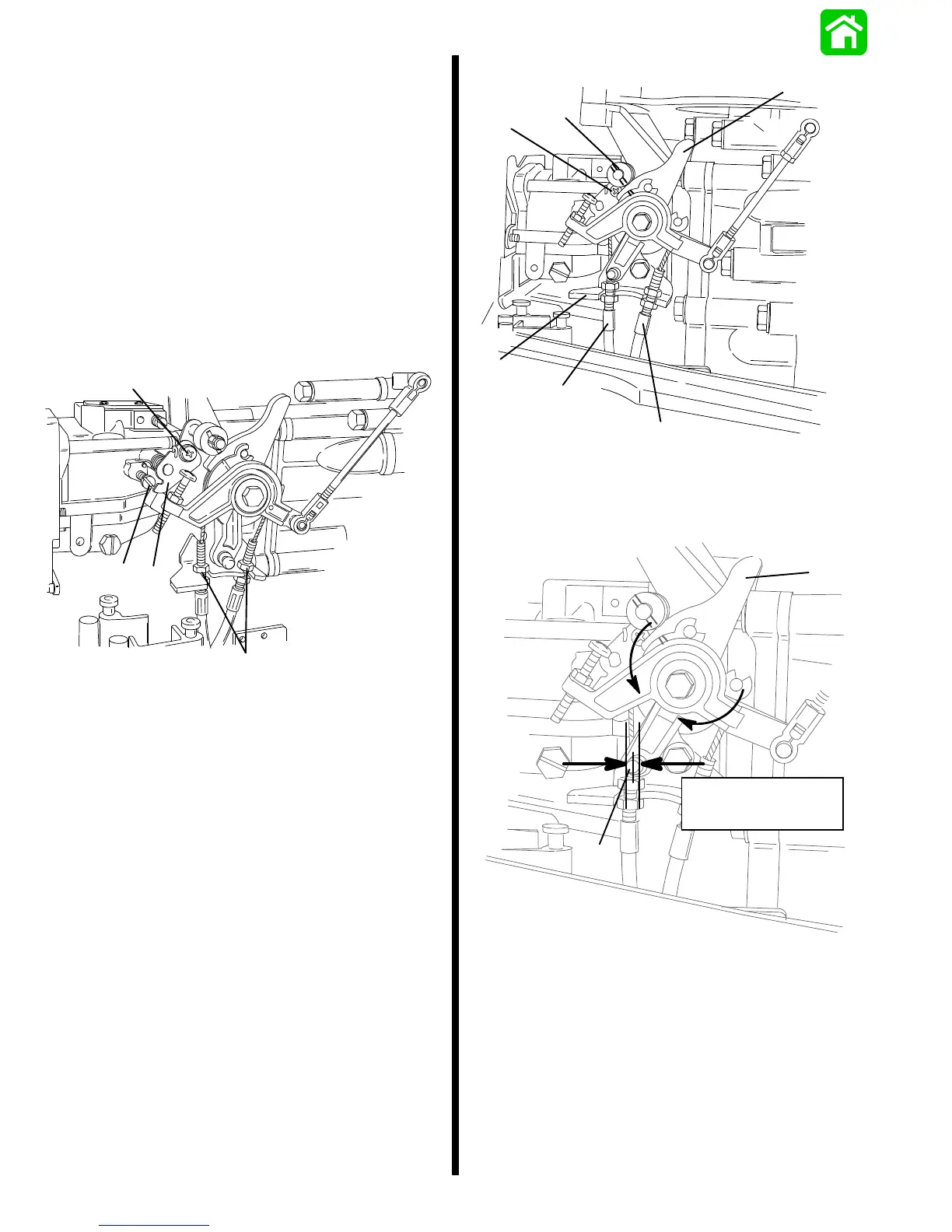

55762

a

b

c

d

e

d

a - Cam Follower Screw

b - Cam Follower Roller

c - Throttle Cam

d - Throttle Cable Sleeve

e - Mounting Bracket

55762

Cable Slack

Min. 1/16 in. (1.59 mm)

Max. 1/8 in. (3.18 mm)

a

b

a - Link Rod Ball

b - Throttle Cam

7. With cam followerresting onthrottlecam,tighten

the cam follower screw.

Loading...

Loading...