6-22 - LOWER UNIT 90-826148R2 MARCH 1997

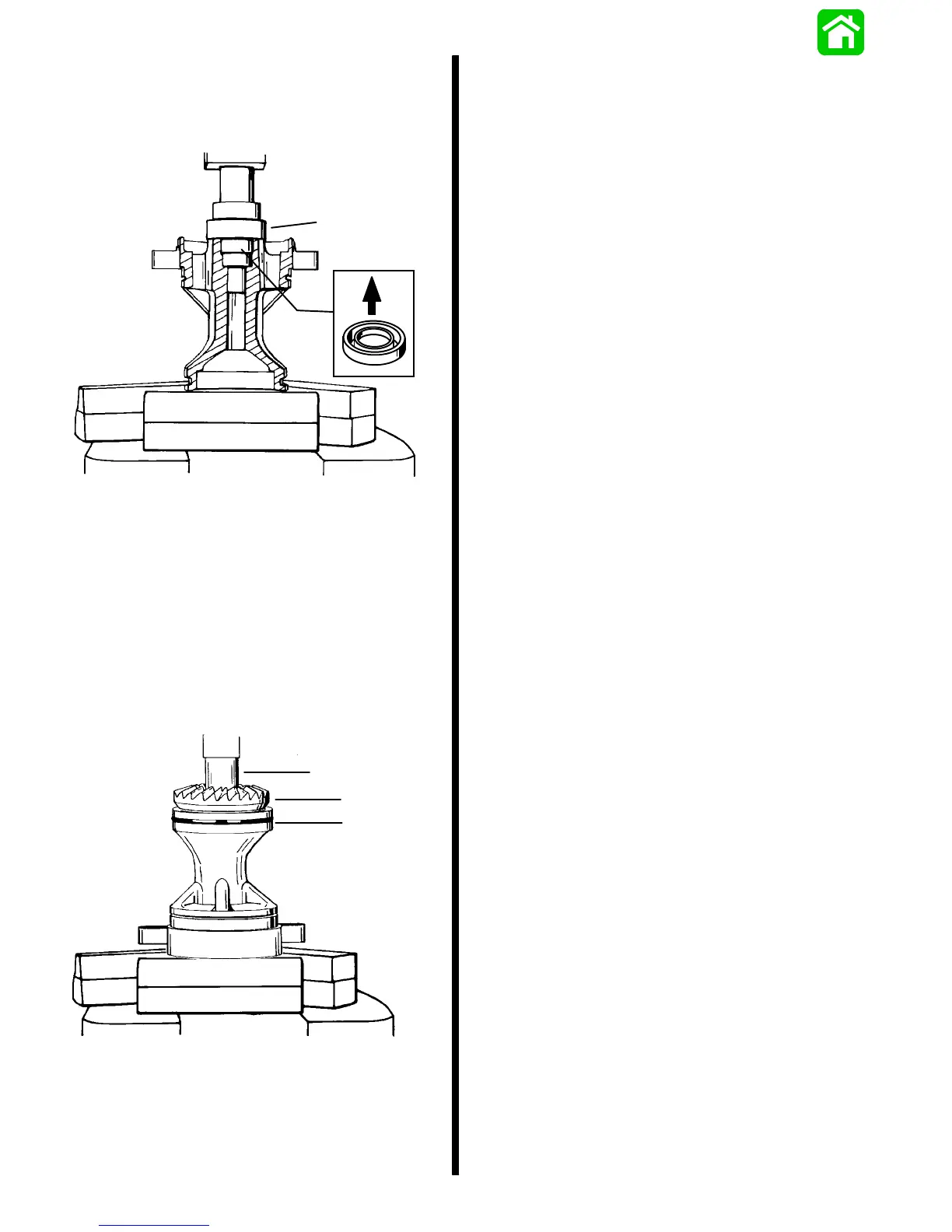

9. Apply Loctite 271 to O.D. of large diameter seal.

10. With seal lip FACING TOWARDS SMALL

SHOULDER of Mandrel 91-817007, press seal

into carrier until mandrel bottoms on carrier.

52863

a

b

a - Seal

b - Mandrel (91-817007)

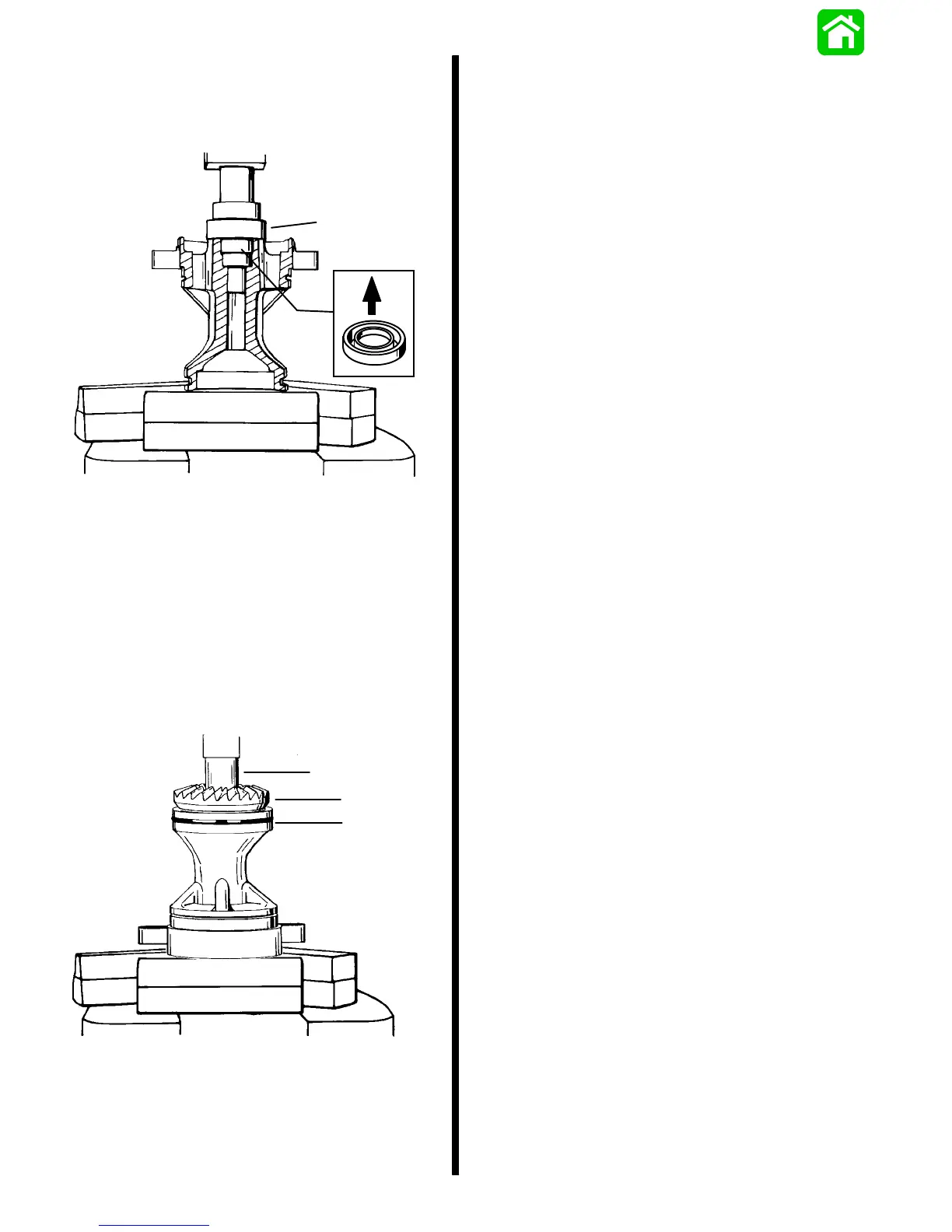

11. Bearing carrier o-ring should be inspected for

cuts and abrasions.

NOTE: It is a good repair procedure to replace all o-

rings and seals regardless of appearance.

12. Apply2-4-Cw/Teflontoo-ringandinstalloncarri-

er.

13. Using suitable mandrel, press reverse gear as-

sembly into carrier.

52827

a

b

c

a - O-ring

b - Mandrel (3/4 in. Socket)

c - Reverse Gear Assembly

Gear Housing Reassembly

IMPORTANT: The30/40gear caseassemblydoes

nothavehaveanyshimsforthegearassemblies.

Backlash cannot be adjusted. The mechanic

must verify that all bearing races are firmly

seated in the gear case during reassembly and

that all gear case components are in serviceable

condition. Prior to installing the seal carrier and

water pump assembly on the drive shaft, the

FORWARD gear should be held stationary (with

ascrewdriverorsimilartool).Whilepullingupon

the drive shaft, lightly turn the shaft back and

forth. A light “clicking” sound should be heard

indicating the presence of backlash between

FORWARD and PINION gears. If this backlash is

not present, the pinion gear race and/or forward

gear race are not fully seated. Races should be

removed and inspected for debris. Reinstall

races and check backlash. If backlash is still not

present, replace gear housing.

Shift Shaft Assembly

1. Apply 2-4-C w/Teflon (92-825407A12) to new o-

rings and install o-ringson shift shaft and carrier.

2. Install carrier on shift shaft.

IMPORTANT: When installing shift shaft assem-

bly into gear housing, DO NOT BOTTOM OUT

SHAFT IN HOUSING. Pull up on shift shaft until

shift boot is not deformed. If shaft is bottomed

out, cross pin in clutch dog will be bent by cam

follower when tightening carrier bolts.

3. Installshiftshaft/carrierassemblyintogearhous-

ing.

4. Secure boot to carrier with sta-strap.

Loading...

Loading...