3C-8 - OIL INJECTION SYSTEM 90-826148R2 MARCH 1997

Troubleshooting

Bleeding Air From Oil Injection

System

CAUTION

If air exists in either oil pump hose (inlet or out-

let), the air MUST BE bled from hose(s) or engine

damage may occur.

BLEEDING AIR FROM OIL PUMP INLET HOSE

Withenginenotrunning,placeashoptowelbelowoil

pump.Loosenbleedscrew threetofourturnsandal-

lowair bubblestoexit inlet hose.Torque bleedscrew

to 25 lb. in. (2.8 N·m). This procedure also allows oil

pump to fill with oil.

BLEEDING AIR FROM OIL PUMP OUTLET

HOSE

Purgeairfromoutlethosebyrunningengine(on50:1

gasoline/oilmixtureinfueltank)atidle speeduntil no

air bubbles are present in outlet hose.

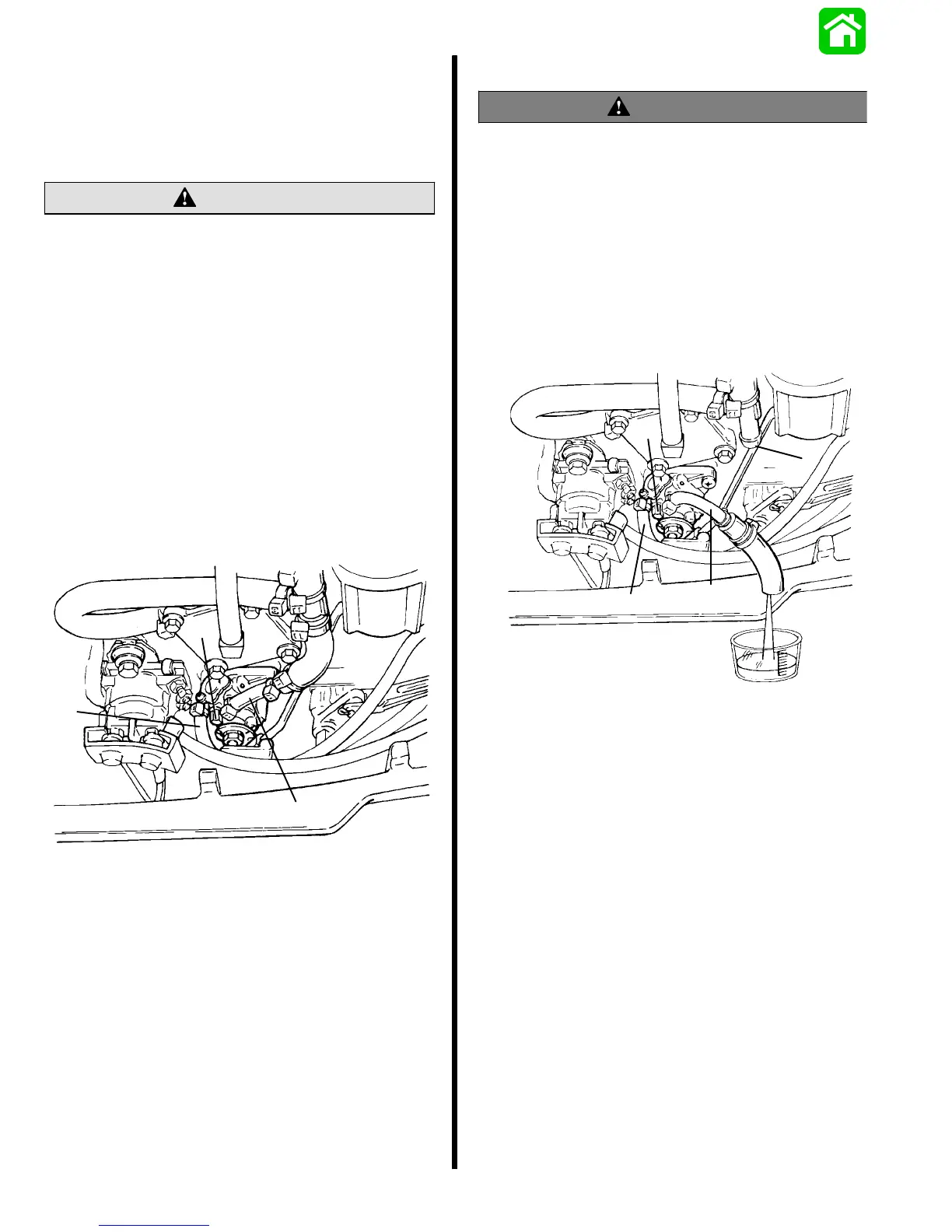

52899

c

a

b

a - Bleed Screw

b - Inlet Hose

c - Outlet Hose

Oil Pump Volume (Flow) Test

WARNING

The input fuel line TEE fitting from which the oil

line was removed MUST BE CAPPED OFF to pre-

vent fuel leakage while the engine is running.

NOTE: The following specifications are determined

with the outboard running off a remote fuel supply

with pre-mix fuel. The oil pump output hose (clear)

mustbedisconnectedfromtheinputfuellineTEEfit-

ting and directed into a graduated container. The in-

putfuel lineTEE fitting from which the oilline was re-

moved MUST BE CAPPED OFF to prevent fuel

leakage while the engine is running.

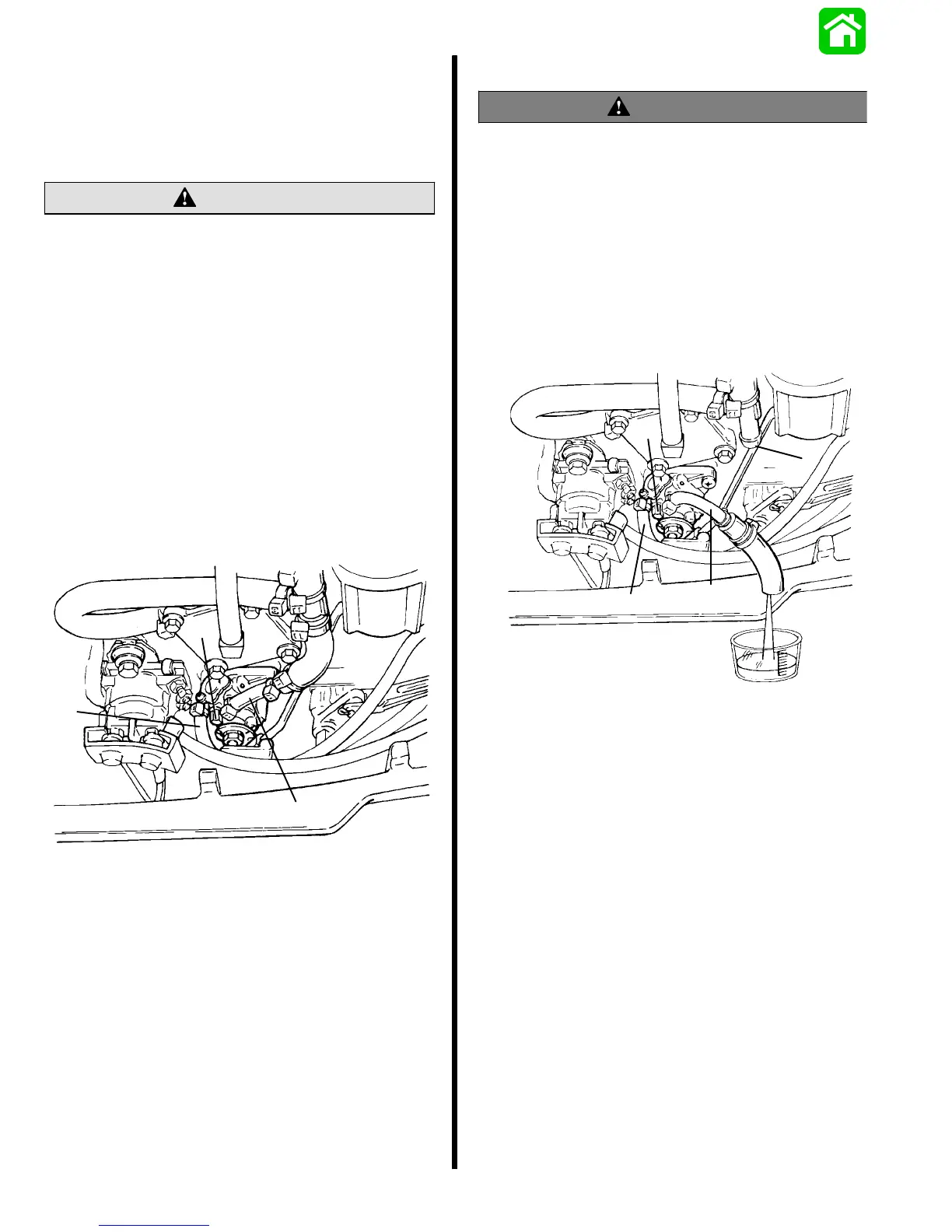

52900

a

b

c

d

a - Bleed Screw

b - Inlet Hose

c - Outlet Hose

d - Cap Off

Flow specifications are as follows:

@900RPMwithoilpumplinkarmDISCONNECTED

and pump arm rotated FULL CLOCKWISE and

HELD AGAINST PUMP CASTING = 8.5cc ± 10% in

10 minutes.

Loading...

Loading...