4-16 - POWERHEAD 90-826148R2 MARCH 1997

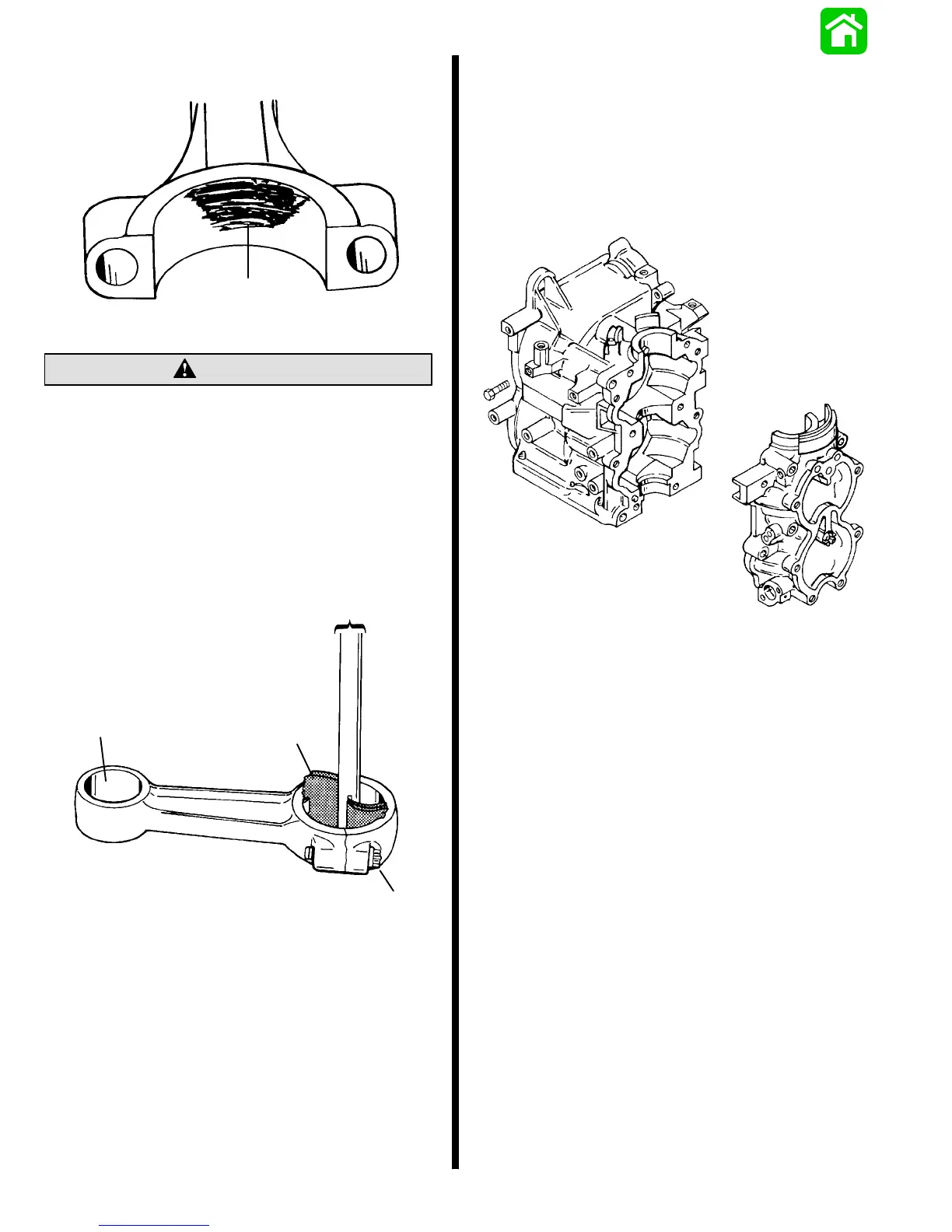

7. Uneven Wear:Unevenwear couldbecausedby

a bent connecting rod.

51853

a

a - Uneven Wear Between Arrows

CAUTION

Crocus cloth MUST BE USED to clean bearing

surface at CRANKSHAFT END OF CONNECTING

ROD.

320 grit Carborundum cloth MUST BE USED to

clean bearing surface at PISTON PIN END OF

CONNECTING ROD.

VERIFY CAP TO ROD ALIGNMENT BEFORE

TORQUING ROD BOLTS.

DO NOT continue to clean connecting rod bear-

ing surfaces after marks have been removed.

51083

NOTE: Wash rod to remove abrasive grit and

apply 2 cycle oil to bearing surfaces to

prevent rust.

a

b

c

d

a - 320 Carborundum Cloth

b - Crocus Cloth

c - To Drill Motor

d - Torque to 16 lb. (21.7 N×m)

NOTE: Wash rod to remove abrasive grit and apply

2 cycle oil to bearing surfaces to prevent rust.

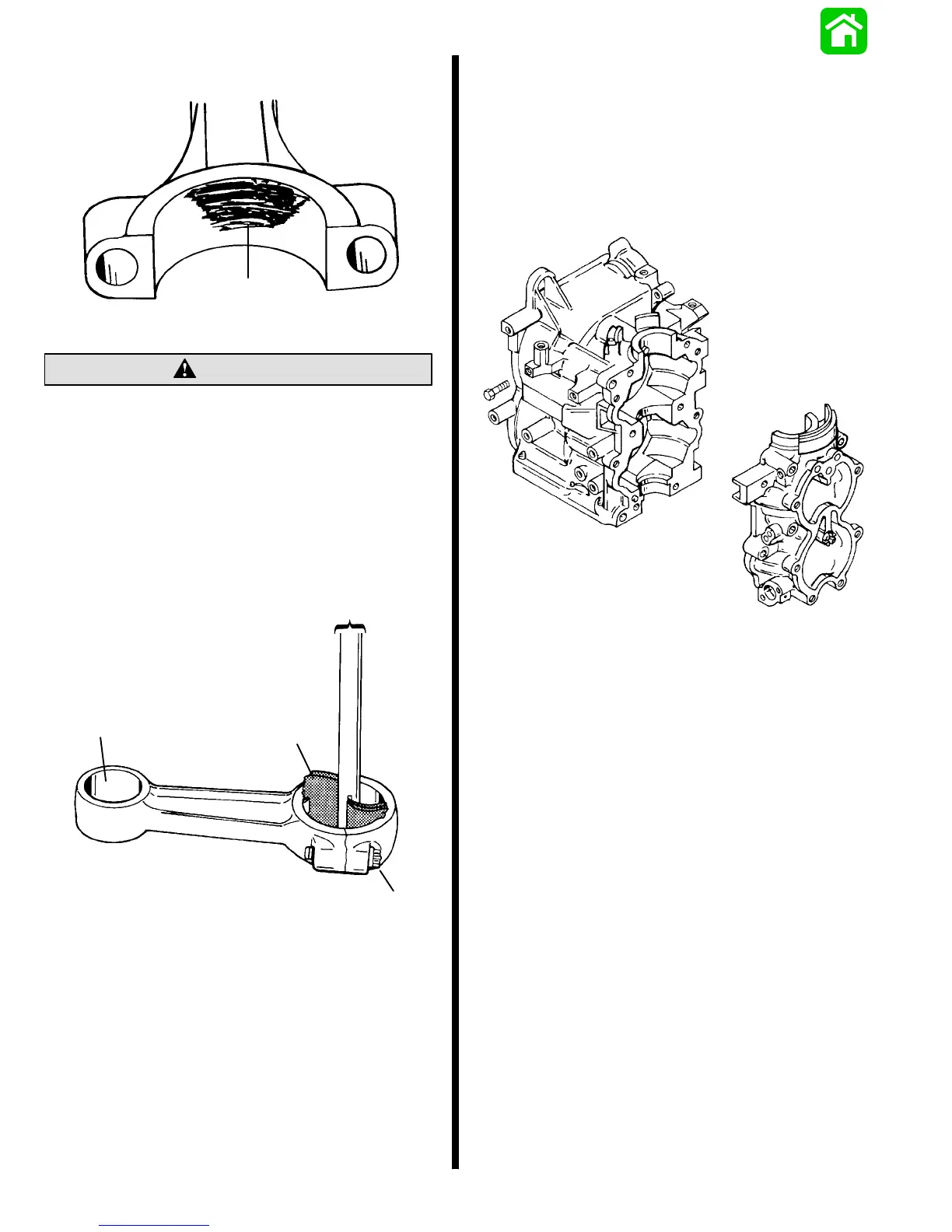

Cleaning and Inspection

Cylinder Block and Crankcase Cover

IMPORTANT: Crankcase cover and cylinder

block are matched, line-bored assembly should

not be mismatched by using a different crank-

case cover or cylinder block.

52651

· Inspect cylinder block and crankcase cover for

cracks or fractures.

· Check gasket surfaces for nicks, deep grooves,

cracks and distortions that could causecompres-

sion leakages.

· Check that all water passages in cylinder block

arenotobstructed.Checklocatingpinsincylinder

block that they are tight.

· Check crankcase cover fuel/bleed passages that

they are not obstructed. Verify that check valves

in crankcase cover are not damaged.

· Thoroughly clean cylinder block and crankcase

cover. Verify that all sealant and old gaskets are

removed from matching surfaces. Clean all car-

bon deposits from exhaust ports.

· Inspect spark plugholes for stripped or damaged

threads.

Loading...

Loading...