4-2

Troubleshooting

When you feel that the device is broken, first refer to the items below:

If the problem is still not solved after troubleshooting, contact your distributor or our service office.

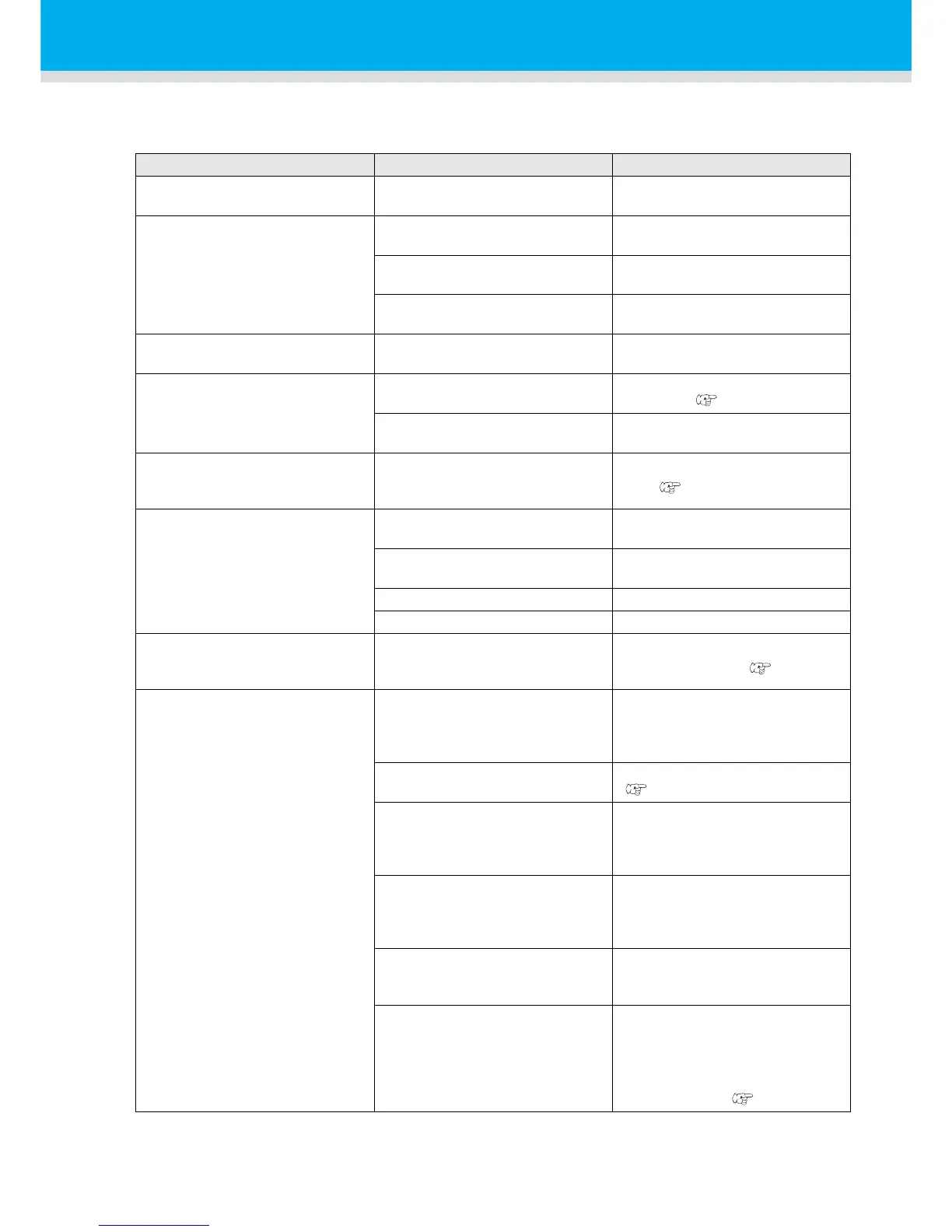

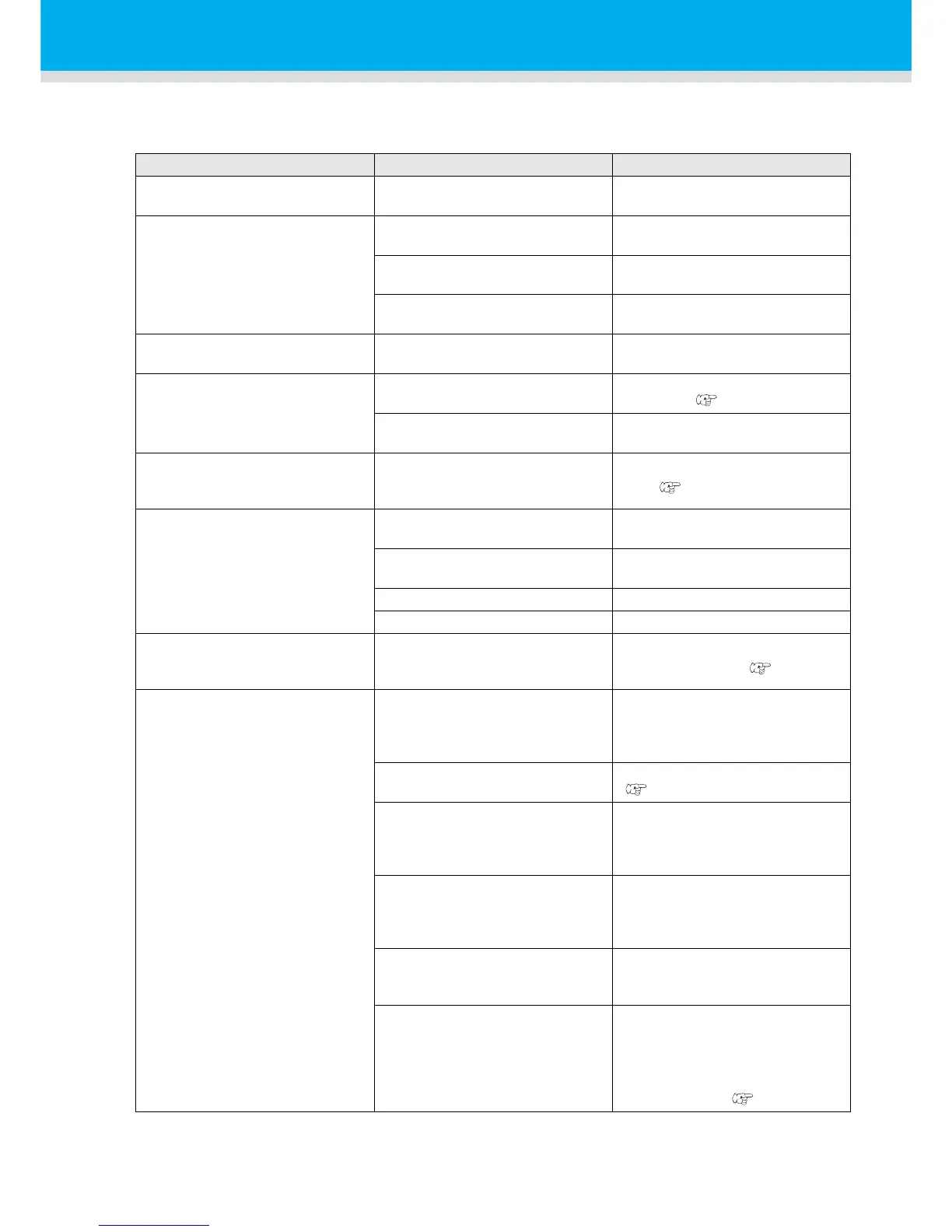

Failure phenomenon Cause Solution

Power does not turn ON.

The power cable of the machine is

not connected securely.

Securely connect the power cable

of the machine to the outlet.

Cutting (plotting) cannot be

performed.

The host computer setting (plotter

name, etc.) is wrong.

Check the host computer setting.

The interface cable is not connected

securely.

Securely connect the interface

cable in position.

The USB driver or Port monitor is

not installed.

Install the USB driver and the port

monitor in the attached manual CD.

A communication error occurs

before receiving data.

The order to turn on the power is

wrong.

Before turning on the power of this

device, turn on the host computer.

An error occurs in the machine

when the host computer sends

data to the machine.

The communication condition is

wrong.

Check the communications

conditions. ( P.3-17)

The wrong operation was

performed.

Operate this machine correctly.

The sheet cannot be detected.

([**NO SHEET**] is displayed on

the screen.)

A black sheet is being used.

Set the sheet sensor function to

OFF. ( P.3-24)

The cut part became a dotted

line.

Screw for the tool holder is loose.

Tighten the knob of the tool holder

further.

The cutter blade protrudes

excessively.

Adjust the blade protruding amount

to the proper one.

The blade is chipped or worn out. Replace the blade with a new one.

The rotation of the blade is dull. Replace the holder with a new one.

Data length differs from the cut

length.

Because the sheet feeding length

differs depending on the sheet

thickness.

Correct the difference by performing

distance correction. ( P.3-10)

Misalignment occurs in cutting.

The pinch rollers and grit rollers fail

to securely retain the sheet in

position.

Check the position of the pinch

rollers and grit roller and adjust

them so that they securely retain the

sheet in position.

The selection of clamp pressure

(strength mode) is not proper.

Select the clamp pressure properly.

(P.1-7)

There is a slack in the roll sheet so

the sheet fed meanders or skews.

When you set roll sheet, first

remove a slack in the roll and make

the right and left edges of the roll

even. Then, perform sheet feeding.

The sheet comes in contact with the

floor surface. (The front end of the

sheet is cut skewed.)

Decrease the cutting speed

(SPEED) to reduce the load on the

sheet when it comes in contact with

the floor surface.

The side margins of the media

beside the pinch rollers are not

enough.

Provide a side margin of 20 mm or

more on each side of the media

beside the pinch rollers.

The sheet extended and shrunk due

to the effect of work environment

(temperature and humidity).

The size of the sheet changes due

to the temperature and the humidity.

First, use the pre-feed function and

acclimate the sheet to the work

environment enough. Then, perform

cutting (plotting). ( P.3-28)

Loading...

Loading...