21.

21 - 1

MAINTENANCE AND INSPECTION

21 MAINTENANCE AND INSPECTION

In order to use the PLC always in good condition, conducting daily and periodical

maintenance/inspection on the following items are strongly recommended.

21.1 Daily Inspection

Dairy inspection items recommended are shown in Table 21.1.

REMARK

If an I/O module has to be replaced when the system is running, use the "online I/O

module replacement" function.

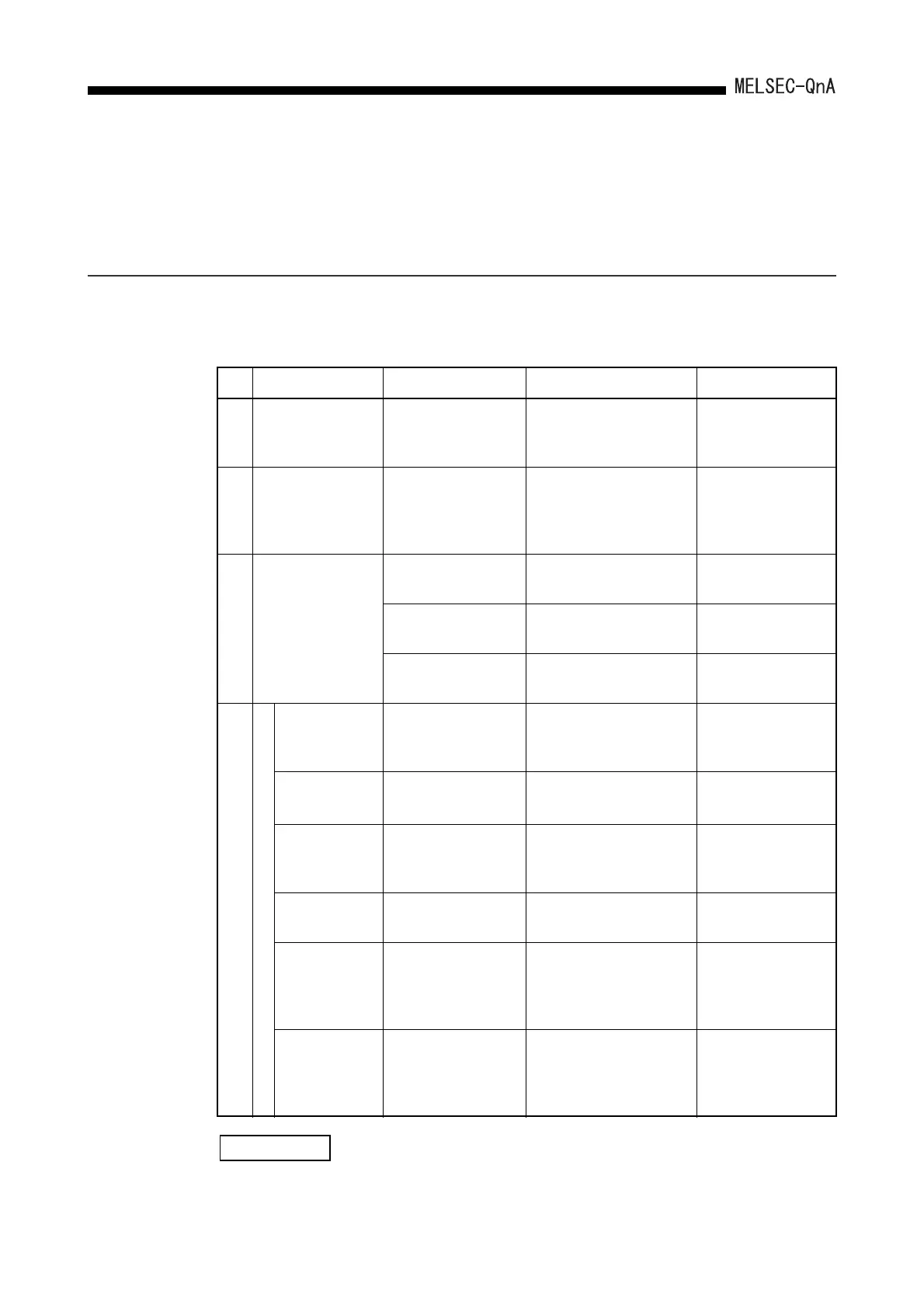

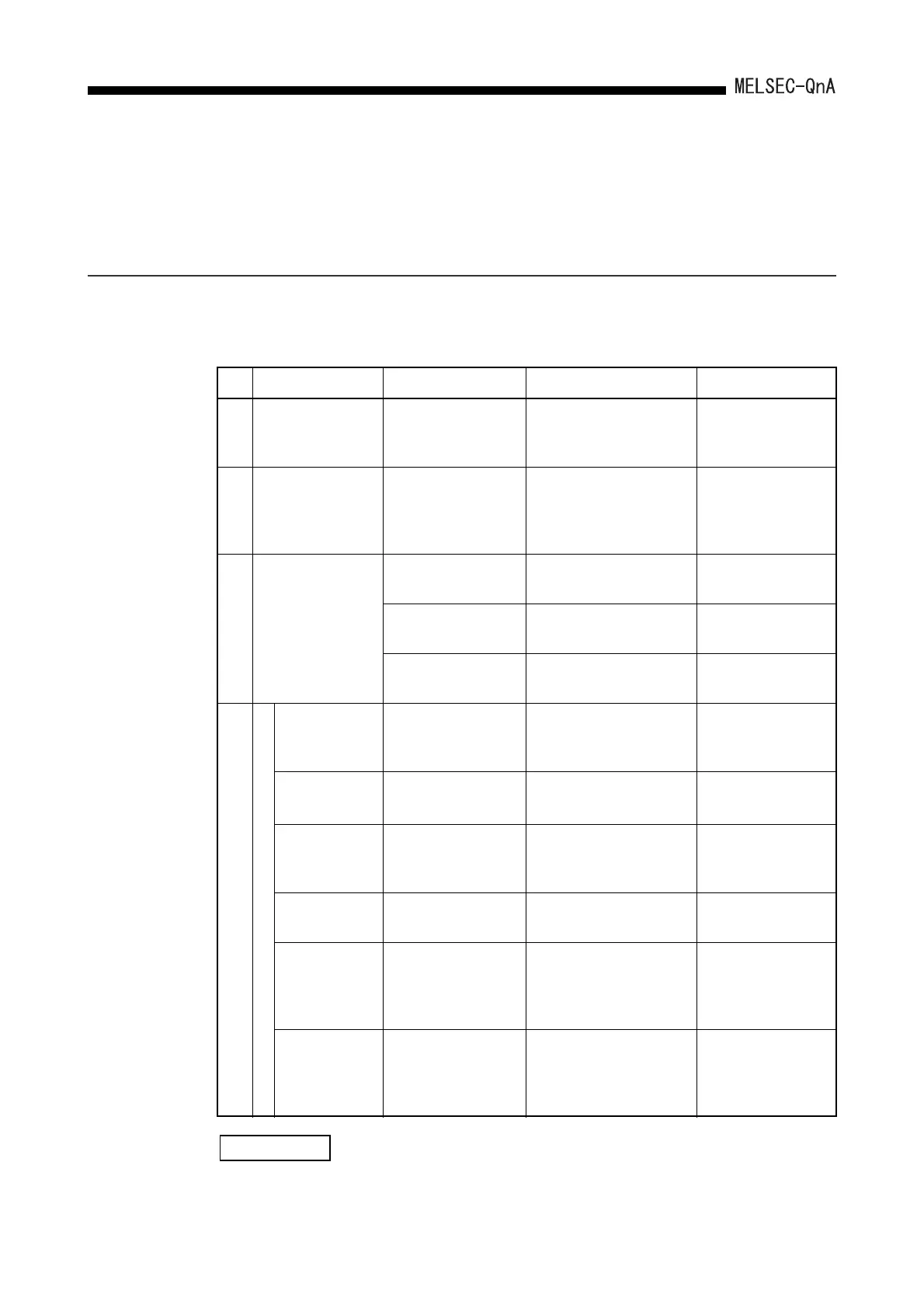

Table 21.1 Daily inspection

Item Check item Content of inspection Judgement Action

1

Installation condition

of the base unit

Confirm if installation

screws are not loose or

cover is not detached.

It is installed securely. Retighten the screw.

2

Installation condition

of the I/O modules

Check if the module is

not disengaged and if

the hook is securely

engaged.

The hook should be securely

engaged and the module

should be positively

mounted.

Securely engage the

hook.

3

Connection

conditions

Loosening of terminal

screw.

No loosening.

Retighten the terminal

screw.

Proximity of solderless

terminals.

There is an appropriate

distance.

Correct the distance.

Connector areas of

extension cable.

No loosening at connectors.

Retighten the

connector fixing screw.

4

LEDs on the main module

Power supply

module

POWER LED

Confirm it is ON.

The LED is ON.

(Faulty if it is OFF.)

Refer to Section 22.2.2.

CPU module

"RUN" LED

Confirm it is ON in the

"RUN" state.

The LED is ON.

(Faulty if it is OFF.)

Refer to

CPU module

"ERROR" LED

Check that the LED is

OFF.

OFF

(Faulty if it is ON or

flickering.)

Refer to Section 22.2.5.

CPU module

"BAT. ARM" LED

Check that the LED is

OFF.

OFF

(Faulty if it is ON.)

Refer to Section 22.2.7.

Input module

LED

Confirm if it correctly

turns on and off.

The LED is ON when input is

ON, and OFF when input is

OFF.

(Faulty other than the above.)

Refer to Section 22.2.8.

Output module

LED

Confirm if it correctly

turns on and off.

The LED is ON when output

is ON, and OFF when output

is OFF.

(Faulty other than the above.)

Refer to Section 22.2.8.

Section 22.2.3.

Section 22.2.4.

Loading...

Loading...