21.

21 - 2

MAINTENANCE AND INSPECTION

21.2 Periodic Inspection

Inspection on items shown below should be conducted once or twice every six months to a

year. Conduct the inspection when the equipment is moved or modified, or wiring is

changed.

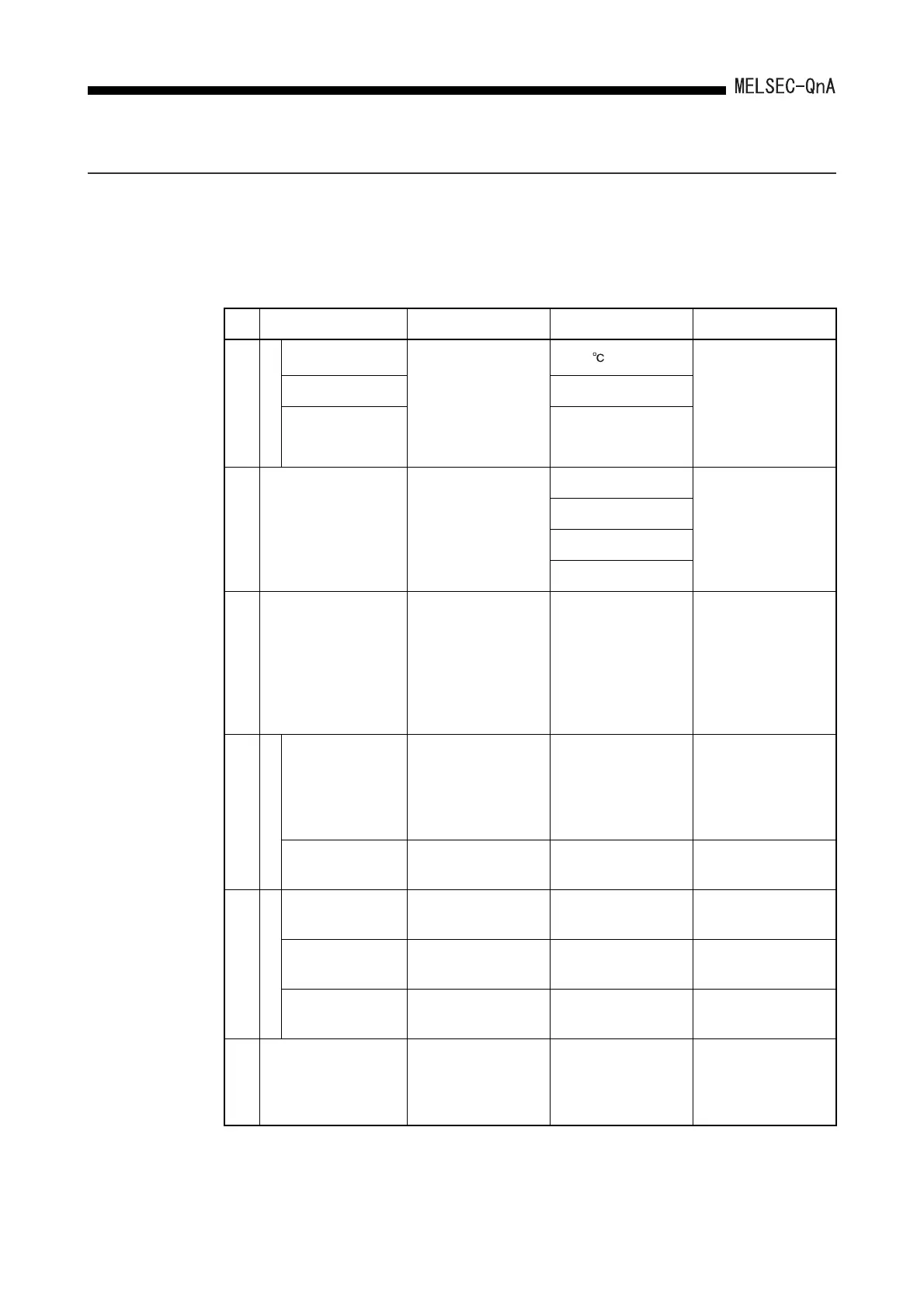

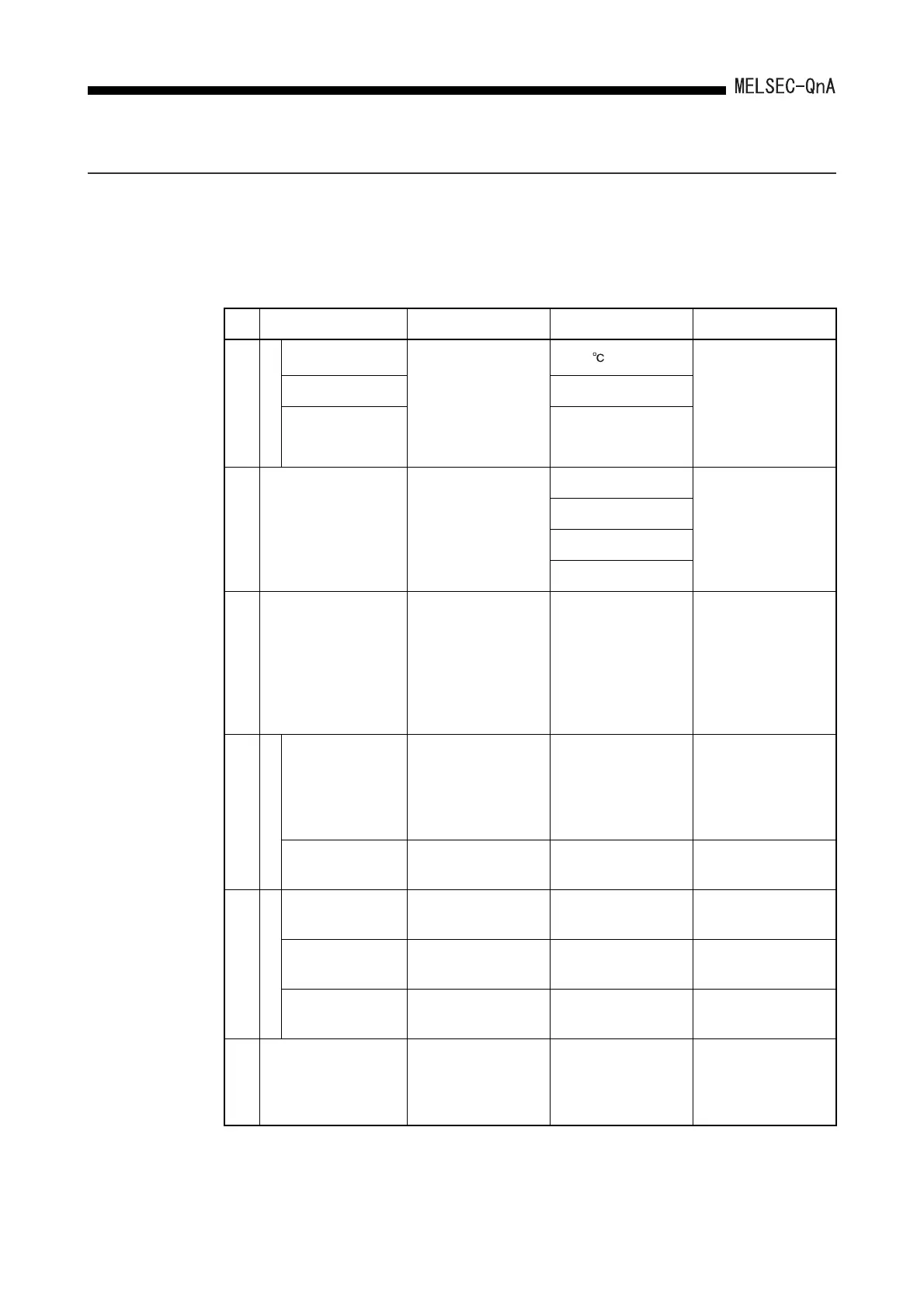

Table 21.2 Periodic inspection

Item Check item Check method Judgement Action

1

Ambient environment

Ambient temperature

Measure with

temperature and

humidity gauge.

Measure presence of

corrosive gases.

0 to 55

When used in a panel,

temperature inside the

panel is the ambient

temperature.

Ambient humidity 10 to 90%RH

Atmosphere

There is no corrosive

gas present.

2 Line voltage check

100/200VAC,

24VDC, 110VDC

Measure voltage across

100/200VAC terminals.

85 to 132VAC

Change the power

supply.

170 to 264VAC

15.6 to 31.2VDC

85 to 140VDC

3Fuse

Check if the fuse is

blown.

(Preventive

maintenance)

Even if a fuse has not

blown, the element may

have deteriorated due to

inrush current, and the

fuse should therefore be

changed at regular

intervals.

4

Installation condition

Loosening, backlash

Test by moving the

module.

Must be installed solidly.

Retighten the screw.

For CPU module, I/O

module, and power

supply modules check

all connections.

Adhesion of dirt or

foreign matters

Visual inspection No adhesion. Remove and clean.

5

Connection conditions

Loosening of

terminal screw

Retighten with a

screwdriver.

No loosening. Retighten.

Proximity of

solderless terminals

Visual inspection

There is an appropriate

distance.

Correct the distance.

Loosening of

connector

Visual inspection No loosening.

Retighten the connector

fixing screw.

6Battery

Confirm SM51 or SM52

is OFF with a peripheral

device in the monitoring

mode.

(Preventive

maintenance)

Even when there is no

low-battery display,

replace if specified life is

exceeded.

Loading...

Loading...