Mechanical mounting

6.3 Installing/removing the rotor

SIMOTICS M-1FE2 built-in motors

Hardware Installation Manual, 04/2020, A5E50074509B AA

99

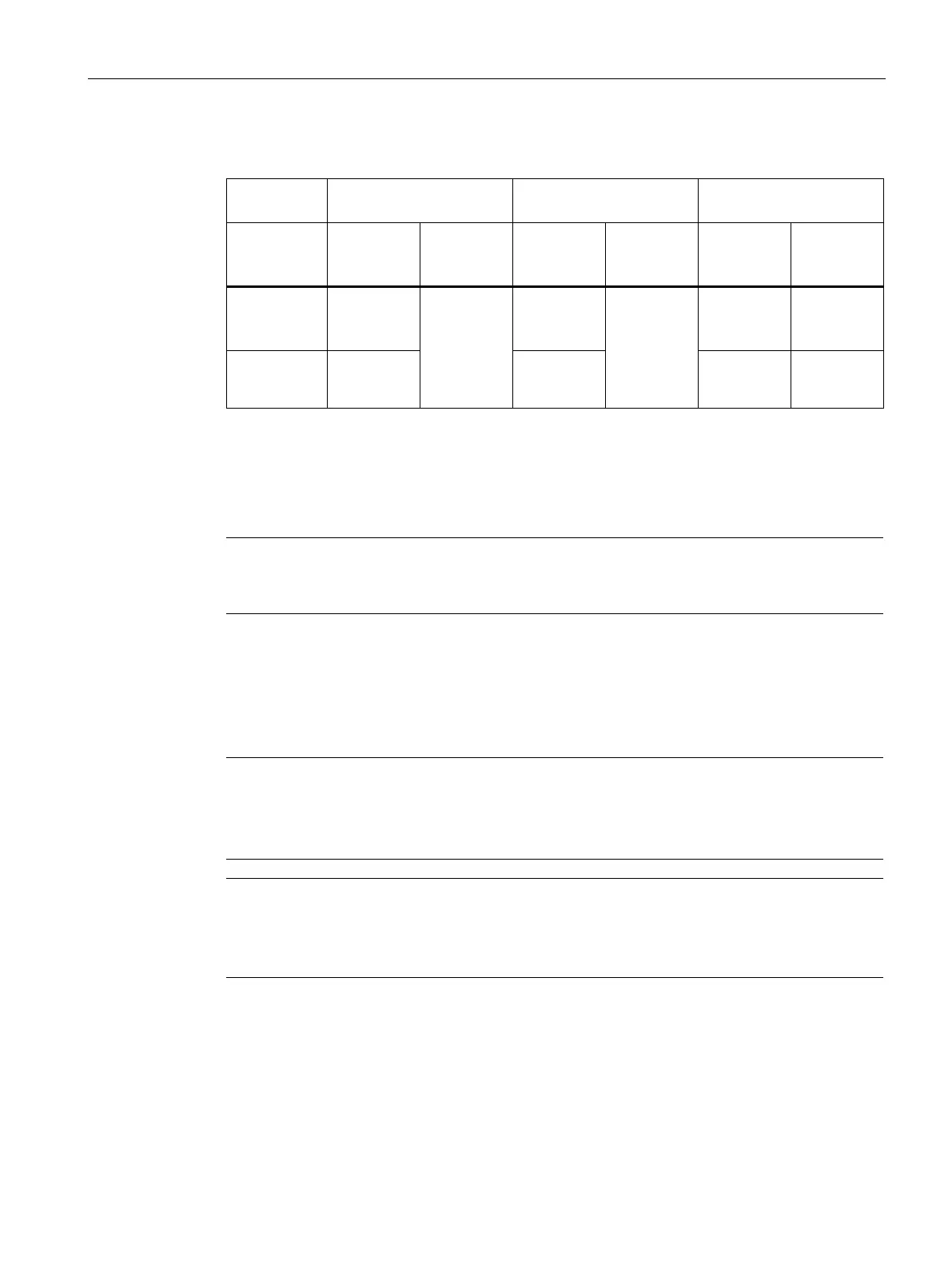

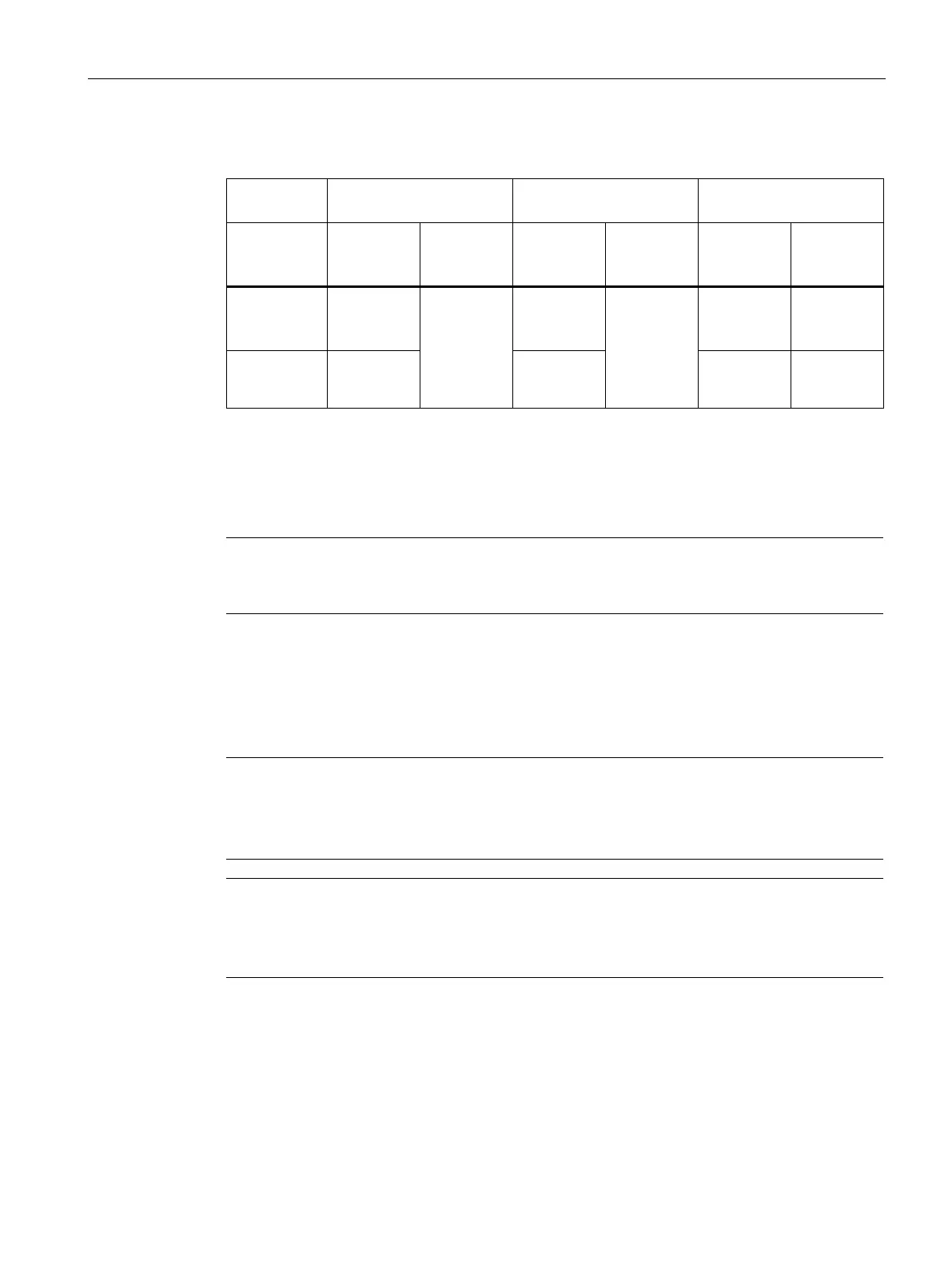

Assembly temperatures

Cold process (stretching)

1)

Combined cold-hot pro-

cess

1)

For asyn-

chronous

version

For asyn-

chronous

version

For asyn-

chronous

version

Temperature

of the rotor

core

135 ...

140 °C

Not recom-

mended

20 ... 40 °C

Not recom-

mended

135 ...

140 °C

270 ...

300 °C

2)

Temperature

of the spindle

shaft

10 ... 20 °C -160 ... -

196 °C

-40 ... -

30 °C

-30 ... 0 °C

2)

After joining, dry the rotor core and spindle shaft (2...3 hours at approx. 60 °C)

2)

The difference in temperature between spindle shaft and rotor core must be at least 300 K.

Requirements for mounting

Note

Depending on the weight of the rotor core, use lifting gear and load suspension devices

capable of carrying the components.

● Check that the resources function properly.

● Check the dimensions of the joining surfaces on the rotor and on the spindle shaft. The

dimensions required for your motor can be found on the dimension sheets in Chapter

"Dimensional drawings (Page 191)".

Note

Avoid positioning errors

•

Carry out the joining procedure without delay.

Observe the position of the holes for the rotor core.

Note

Installing balancing disks

Depending on the type of rotor (without or with sleeve) and the balancing method, you may

have to mount balancing disks together with the rotor on the spindle shaft.

Loading...

Loading...