4. Fuel System

4-8

Assembly

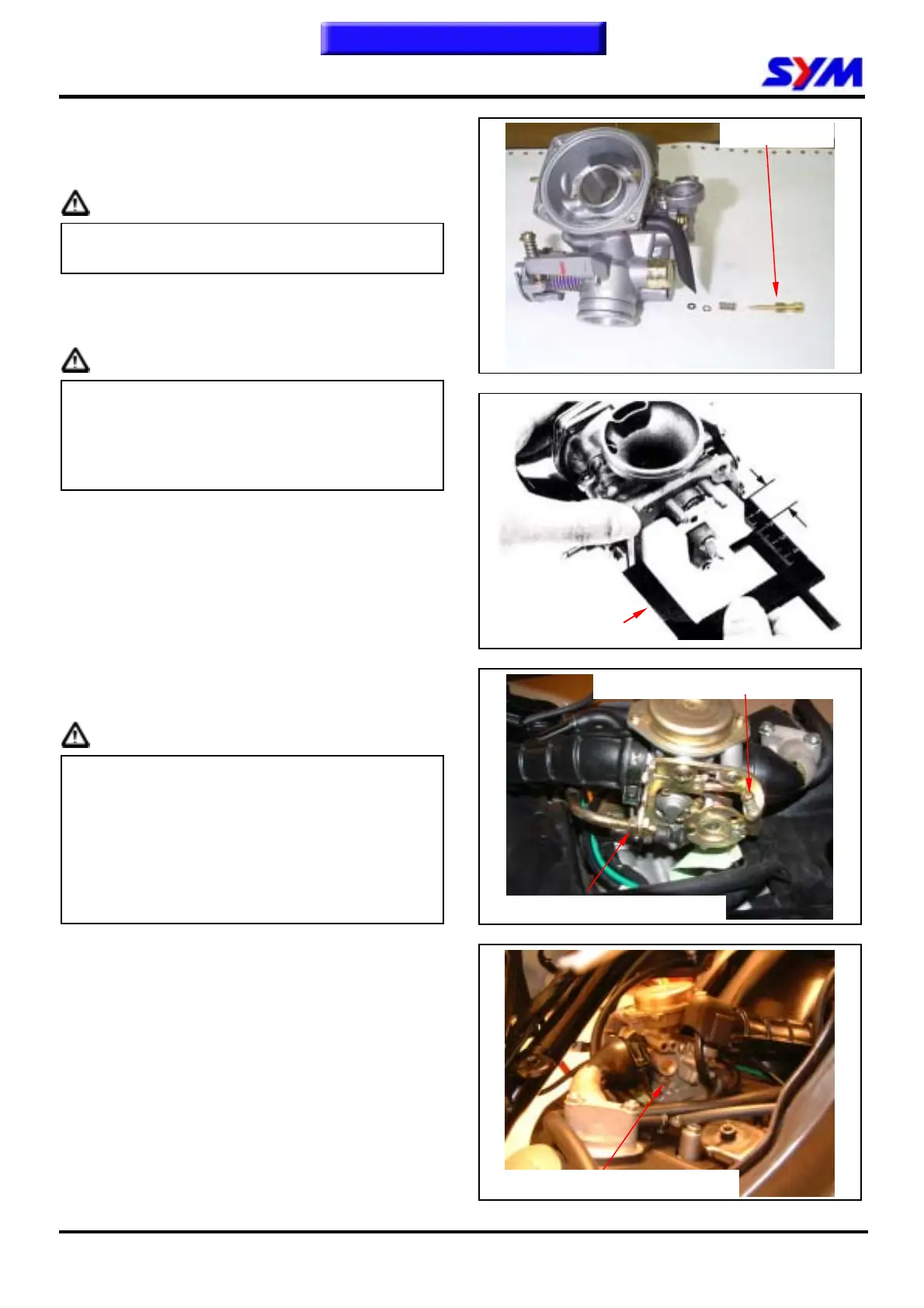

Install main jet, fuel needle jet holder, nozzle, idle

jet and air-fuel mixture adjustment screw.

Caution

z Set the adjustment screw in according to

number of turns noted before it was removed.

Install the float valve, float, and float pin.

Checking Fuel Level

Caution

z Check again to ensure float valve, float for

proper installation.

z To ensure correct measurement, position the

float meter in such a way so that float

chamber face is vertical to the main jet.

Fuel level:16.0 mm

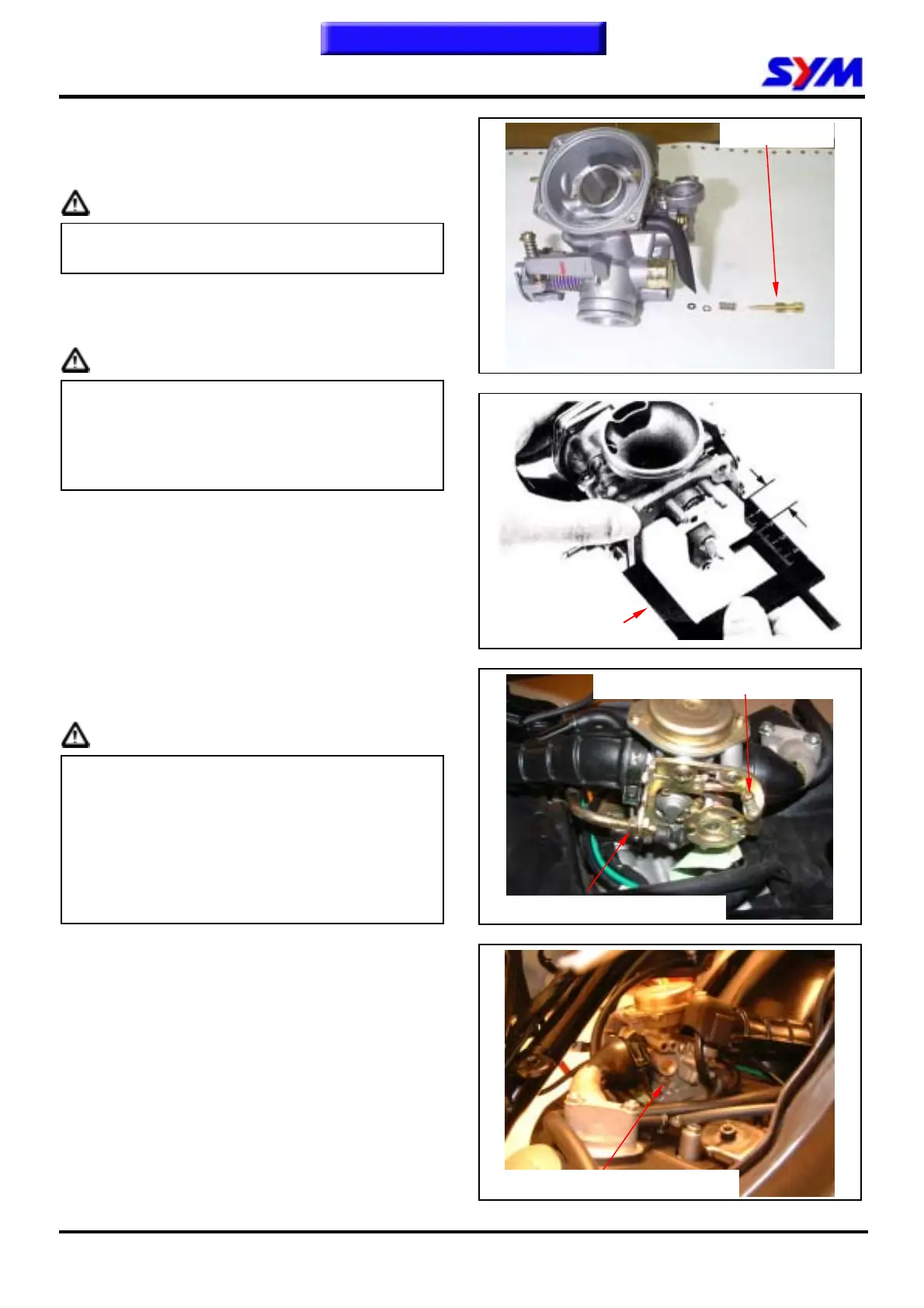

Installation of carburetor

Install carburetor in the reverse order of removal.

Following adjustments must be made after

installation.

y Throttle valve cable clearance adjustment.

y Idle speed adjustment.

Idle Speed Adjustment

Caution

z Air amount adjust screw was set at factory,

so no adjustment is needed. Note the number

of turns it takes to screw it all the way in for

ease of installation.

z Never screw in forcedly to avoid damaging

the screw seat.

z The main stand must be used to support the

motorcycle to perform the adjustments.

Use a tachometer when adjusting engine RPM.

Screw in adjustment screw gently, then back up to

standard turns.

After warm up engine, then adjust the stopper

screw of throttle valve to standard RPM.

Connect the sampling hose of exhaust analyzer to

exhaust front end. Press test key on the analyzer.

Adjust the fuel amount adjustment screw and read

CO reading on the analyzer

CO standard value:1.3~2.0 %

Accelerate in gradual increments, and make sure

both rpm and CO value are in standard values

after engine running in stable. If rpm and CO

value fluctuated, repeat the procedures described

above

Air-fuel mixture

Float level gauge

Adjustment nut of throttle cable

The stopper screw of throttle valve

Air-fuel mixture adjustment screw

To this chapter contents

Loading...

Loading...