20 Dover Fueling Solutions W2940305 Rev 07 8/2019

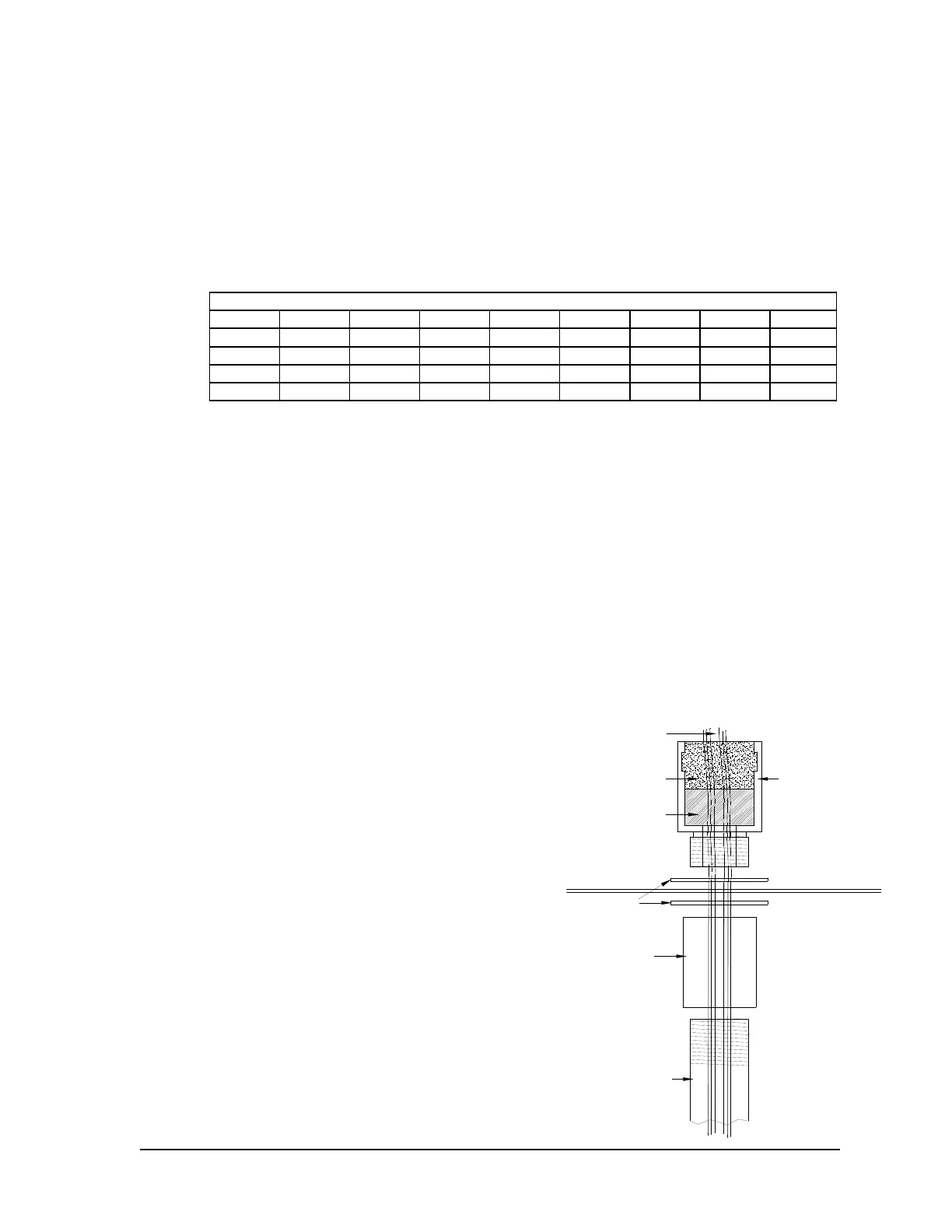

Current 1'-25' 26'-50' 51'-75' 76'-100' 101'-150' 151'-200' 201'-250' 251'-300'

2.5 A1414141414141414

5.0 A1414141414141412

7.5 A1414141414121210

10.0 A1414141412121010

Recommended Wire Size (AWG)

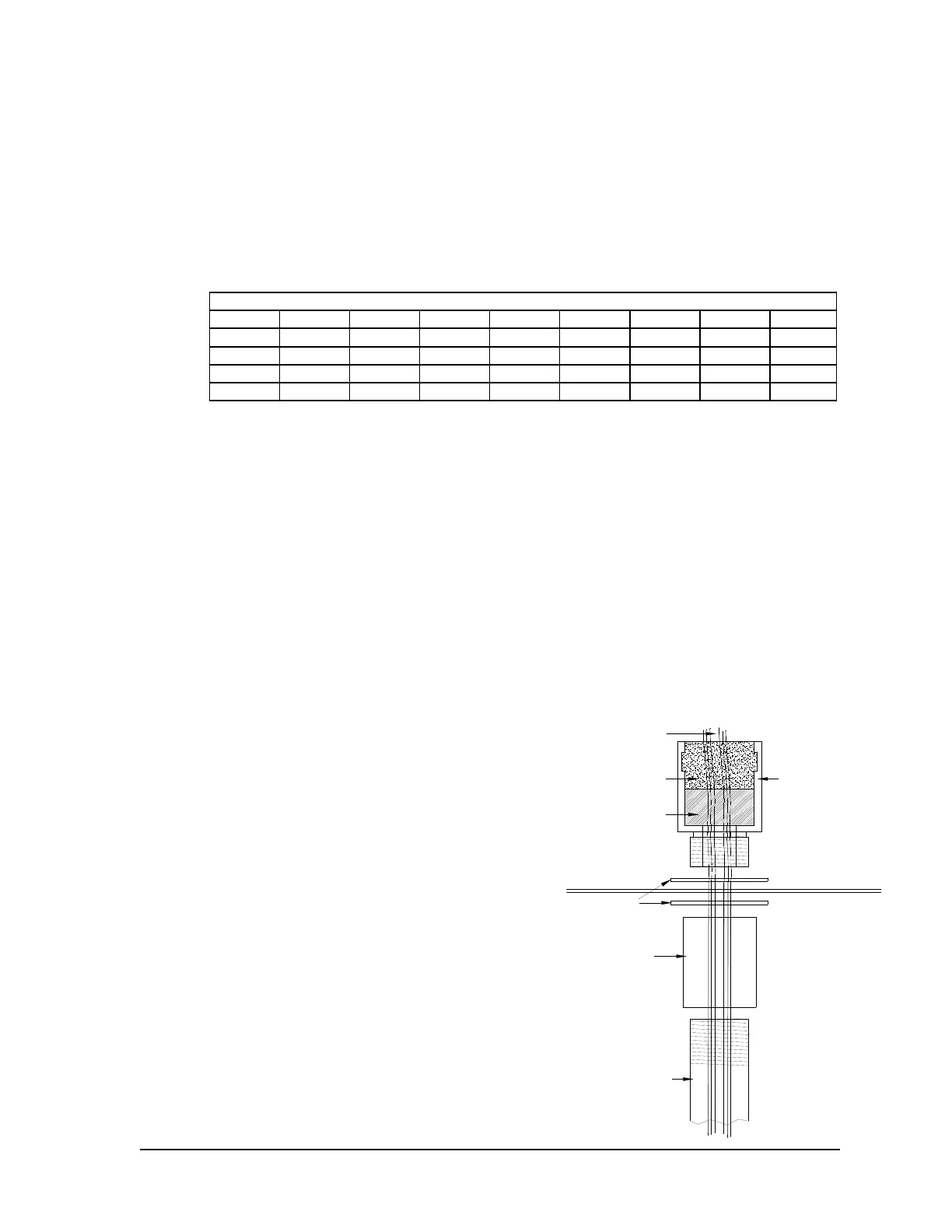

Vapor Barrier

Washer

Coupler

3/4" Conduit

Conduit

Fitting

Potting

Material

Cable &

Wires

Separator

Gasket

3.3.6 Wire Type

All wiring should be UL-Listed, rated for a minimum 90

0

C (194

0

F), 600V, and gasoline

and oil-resistant stranded wire.

All AC wire terminations must be made to the standard and optional terminal blocks as

applicable. Make sure that any unused conduit entry openings are properly plugged.

3.3.6.1 Wire Size

For the Control Wiring, the size of the wire used should be determined by the power

requirements of the dispenser and the length of run from the breaker panel.

For the submersible control line going to submersible starter relays, 14 AWG wire is

recommended for most applications. The wire gauge for the submersible pump should

be determined by the size of the motor and the length of the run according to the

manufacturer’s installation instructions and NFPA 70A.

The wire size for the pulse output must be 18 AWG. The authorization and reset lines

must be no smaller than 18 AWG. Reference the installation instructions of the fuel

control system manufacturer regarding running DC wires with AC wires and the

necessary wire specifications (shielding, etc.).

3.3.7 Conduit

Use UL Listed threaded, rigid, metal conduit and properly sealed connectors. Threaded

connections must be drawn up tight and have a minimum of five threads engaged.

Do not use flexible conduit or knockout boxes.

When connecting to a fuel control system, consult the manufacturer’s instructions for

conduit requirements for AC and DC lines.

The dispenser is provided with a minimum of

two or three ¾” conduit assemblies that are

used to route the field wiring (including the

optional motor wiring) into the head assembly.

Two are provided for standard dispensers and

an extra (the third assembly) is provided with

dispensers equipped with a Pulse Output

option or an iX Fleet terminal. These conduit

assemblies include a conduit fitting (for

potting), 2 washers, a coupling, separator

gasket and a piece of ¾” conduit. The field

wiring must be potted in the fitting provided as

it passes through dispenser’s vapor barrier.

The wires should be separated with the

separator gasket to allow the potting material to

surround each of the wires. The total cross-

section area of the wiring feeding through one

of the conduit fittings is not to exceed 0.092 sq.

in. or 59.6 sq. mm.

Loading...

Loading...