70 Dover Fueling Solutions W2940305 Rev 07 8/2019

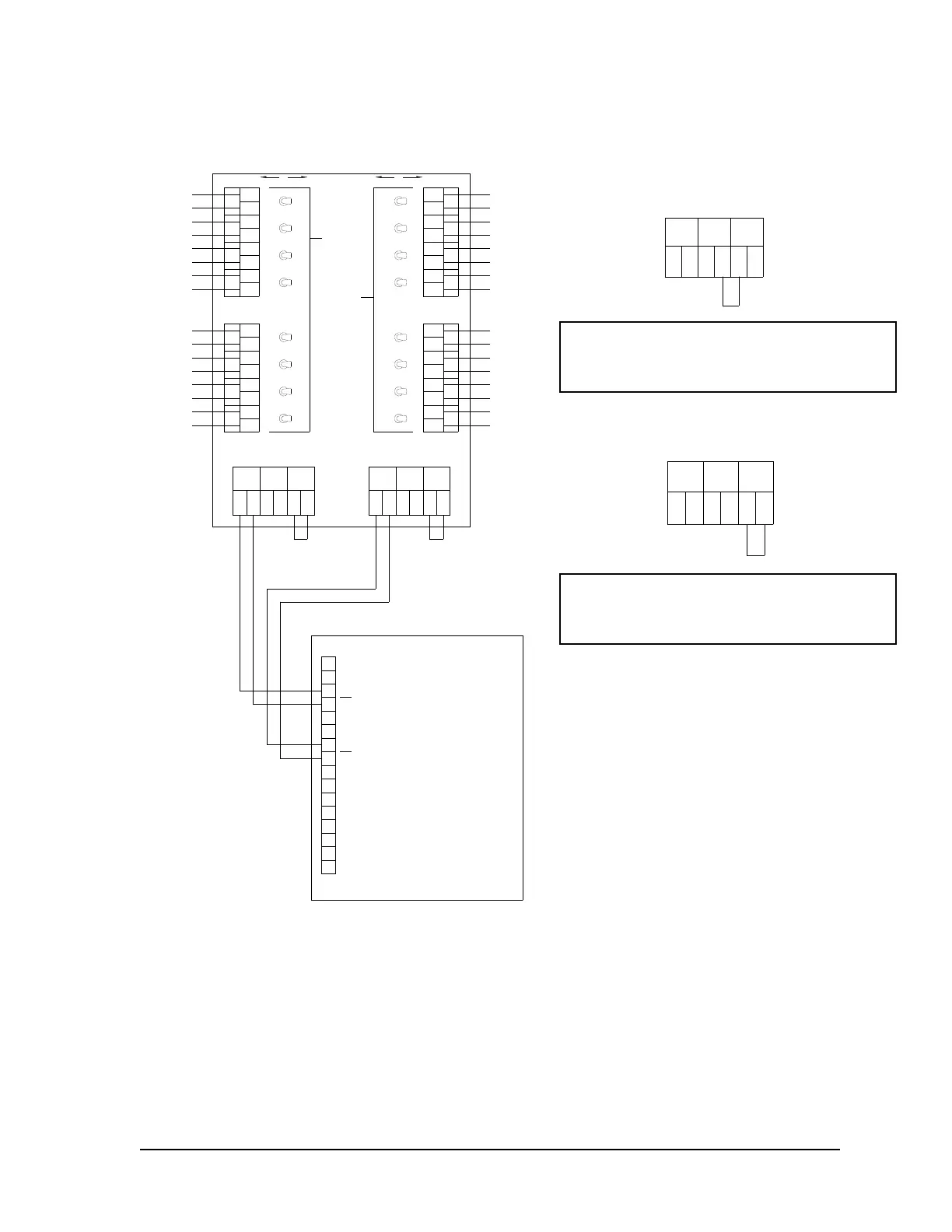

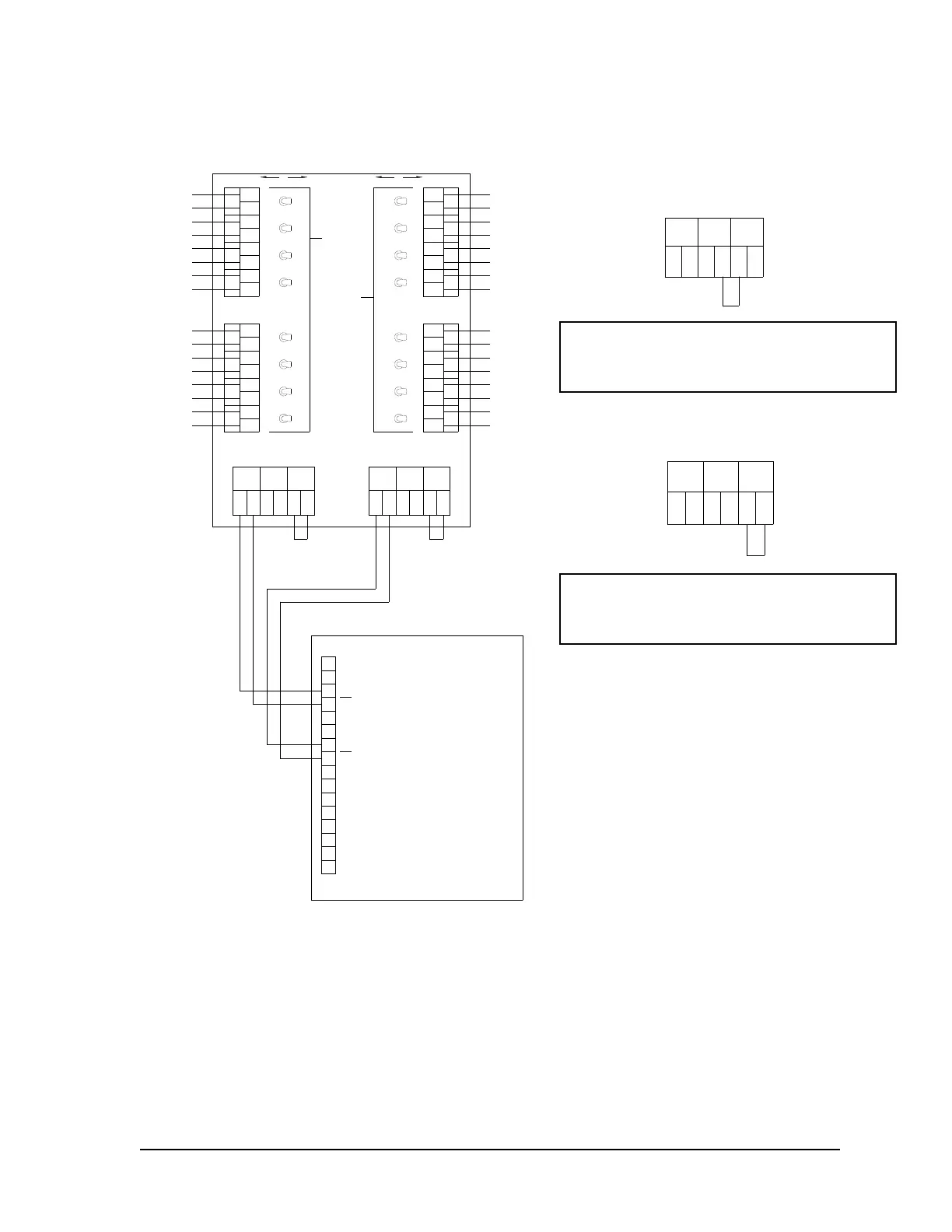

TB5 or TB6

Data

Out

Data

In

+

--

+

563421

TB5 or TB6

12 4

365

+

--

+

Data

In

Data

Out

Current

Loop B

Current

Loop A

Bypass

Auto

Auto

Bypass

65

4

3

21

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

Data

Out

Data

In

Data

Out

Data

In

+

--

++

--

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

+

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

Current

Loop B

Current

Loop A

TB6

TB5

563

421

TB2

TB4

TB3

TB1

+

-

-

+

+

-

-

+

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

Dispenser

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

TB2

Data Distribution Cabinet

HyperPIB

C.7 Wiring Using One Data Distribution Cabinet (Up to 16 dispensers)

Notes:

1. Two Current Loops are provided for communication to the dispensers from the HyperPIB.

Evenly distribute the dispenser loads across both loops in the Data Distribution Cabinet.

2. All unused dispenser positions in the Date Distribution Cabinet should be jumpered in the

cabinet with the switch placed in the “Auto” position. This practice reduces the overall

load on the loop.

3. Each loop in this configuration is limited to 8 dispensers and a total wire length of 1800

feet. This length of 1800 feet includes the distance between the HyperPIB and the Data

Distribution Cabinet as well as the distance between each dispenser and the Data

Distribution Cabinet.

4. See the TB5/TB6 jumper requirements for each loop according to the drawing above.

TB5 is associated with Loop A and TB6 is associated with Loop B.

Jumper positions 4 & 5 for 4 or less

dispensers per loop OR cumulative distances

of less than 150 feet per loop.

Jumper positions 5 & 6 for 5 or more

dispensers per loop OR cumulative distances

of 150 feet or greater per loop.

Loading...

Loading...