146

5.10.4. Auto-Tuning

Enabling the Auto-Tuning function blocks the settings of the

PID parameters.

There are two types: continuous and one-shot.

Continuous Auto-Tuning constantly measures system oscil-

lations, immediately searching for PID parameter values that

reduce the current oscillation. It does not act if the oscilla-

tions drop to values below 1.0% of the Proportional Band.

It is interrupted if the setpoint changes and automatically re-

sumes with a constant setpoint.

The calculated parameters are not latched if the device swi-

tches off, if it goes into manual, or if the configuration code is

disabled.

The controller resumes with the parameters programmed be-

fore enabling Auto-Tuning.

The calculated parameters are latched when the function,

enabled from digital input or key , is disabled.

One-shot” Auto-Tuning can be started manually or automa-

tically. It is useful for calculating PID parameters when the

system is around the setpoint.

“One-shot” Auto-Tuning produces a change in the control

output up to a maximum of ± 100% of current control power

(limited with H.P.HI...H.P.LO for heat and with C.P.HI...C.P.LO

for cool) and evaluates the effects in time overshoot.

The calculated parameters are latched. It starts manually via

digital input or via Tuning key after an undershoot/overshoot.

It starts automatically (with error band of 0.5%) when the

PV-SP error goes beyond the set band (programmable at

0.5%,1%, 2%, 4% of full-scale).

Attention! At power-on or after a setpoint change,

automatic start is inhibited for a time equal to five

times the integral time (with minimum of 5 minu-

tes). The same time has to pass after running “One-

shot” Auto-Tuning.

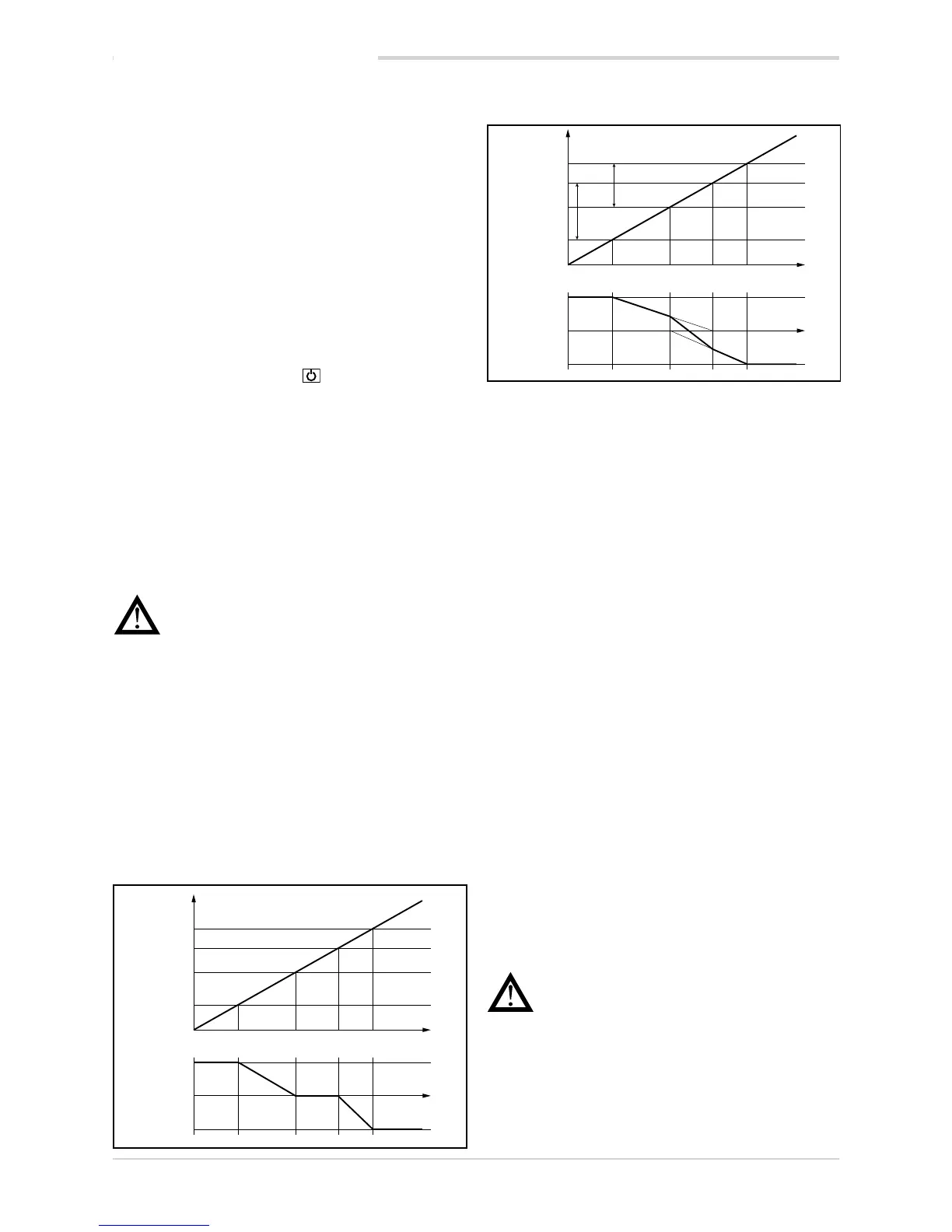

5.10.5. Examples of tuning

The two diagrams below show the time change in the moni-

tored value and the change in the controlled tuning output.

• PV = Process variable

• SP + cSPo = cooling setpoint

• cSPo = C.SP (HI.SCL - LO.SCL) / 100

• C.PB = Proportional cooling band

• SP = heating setpoint

• H.PB = Proportional heating band

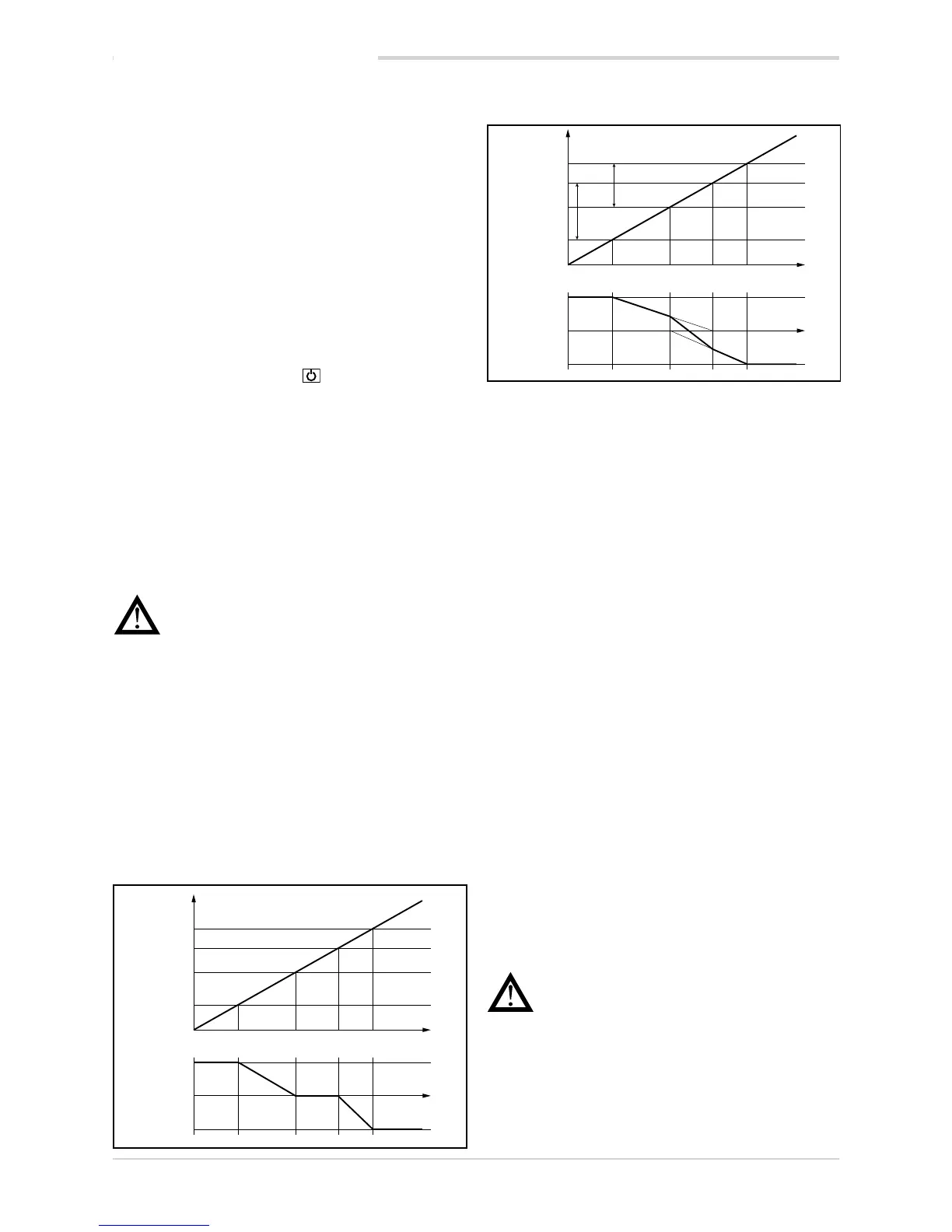

Tuning output only with proportional action in case of pro-

portional heating band separate from cooling band.

Tuning output only with proportional action in case of pro-

portional heating band superimposed on cooling band.

5.10.6. Heat/Cool tuning with relative gain

For this tuning mode (enabled on the PID menu with para-

meter Cntr = PID.RG) you have to specify the cooling type

(COOL parameter).

The PID cooling parameters are calculated starting from

heating parameters in the specified ratios:

• Air relative gain H.PB / C.PB = 1

• Water relative gain H.PB / C.PB = 0.8

• Oil relative gain H.PB / C.PB = 0.4

Example

Starting with the following heat data:

• COOL = oil

• H.PB = 10.0

• H.IT = 4.00

• H.DT = 1.00

there will be the following cool data:

• C.PB = 12.5

• C.IT = 4.00

• C.DT = 1.00

For slicing cycle times for outputs, the following values

should be set:

• Air CY.TIM Cycle T Cool = 10 seconds

• Water CY.TIM Cycle T Cool = 2 seconds

• Oil CY.TIM Cycle T Cool = 4 seconds

Attention! Cool parameters cannot be changed in

this mode.

5. Examples and applicative notes

tempo

+100%

-100%

0%

Loading...

Loading...