CYLINDER/PISTON

• This section covers maintenance of the cylinder and piston. These services require engine removal.

• Be careful not to damage mating surfaces when removing the cylinder.

Do

not tap the cylinder too hard during removal.

• Take care not to damage the cylinder wall and piston.

• Clean all disassembled parts with clean solvent and dry them using compressed air before inspection.

• When removing the piston, clean carbon and sludge from the top

of

the cylinder.

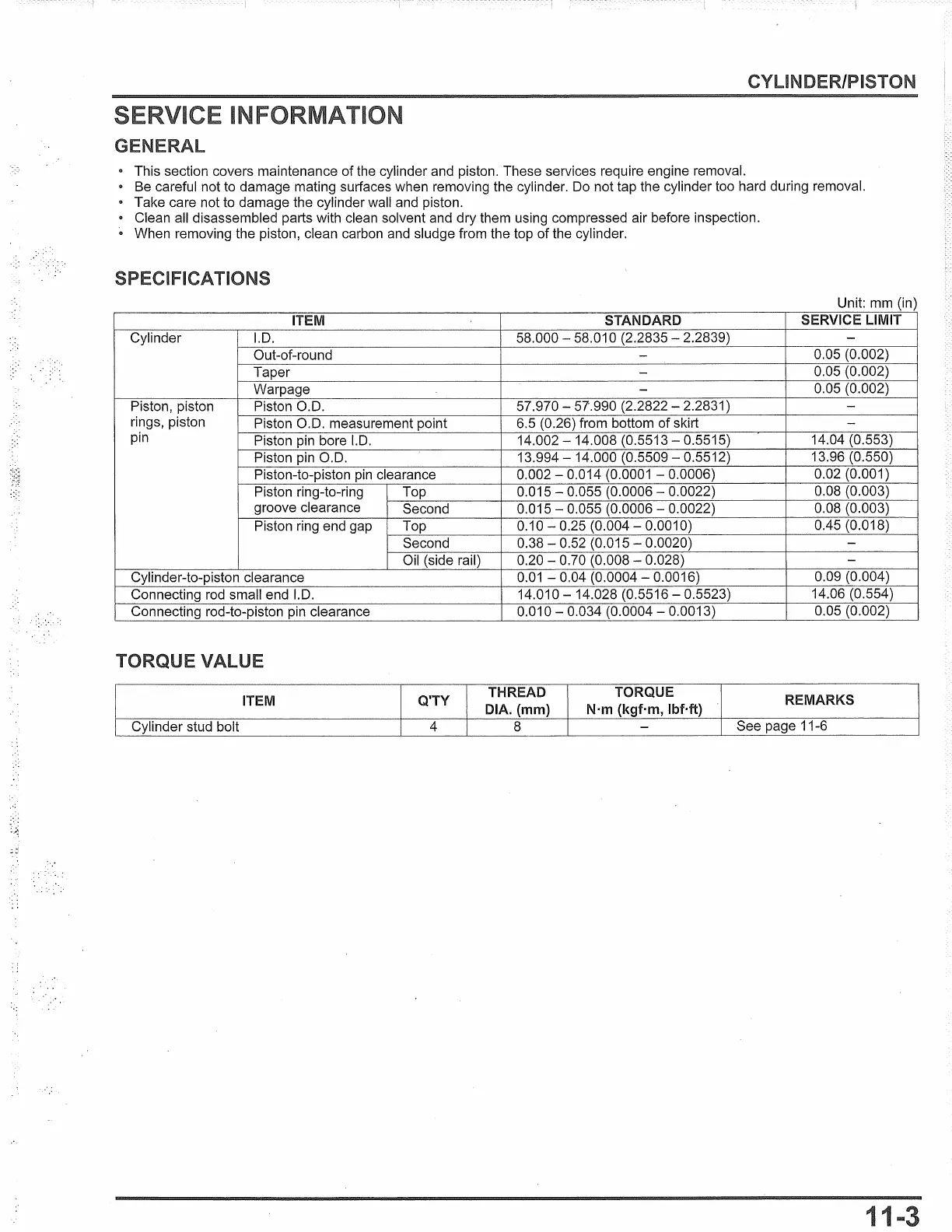

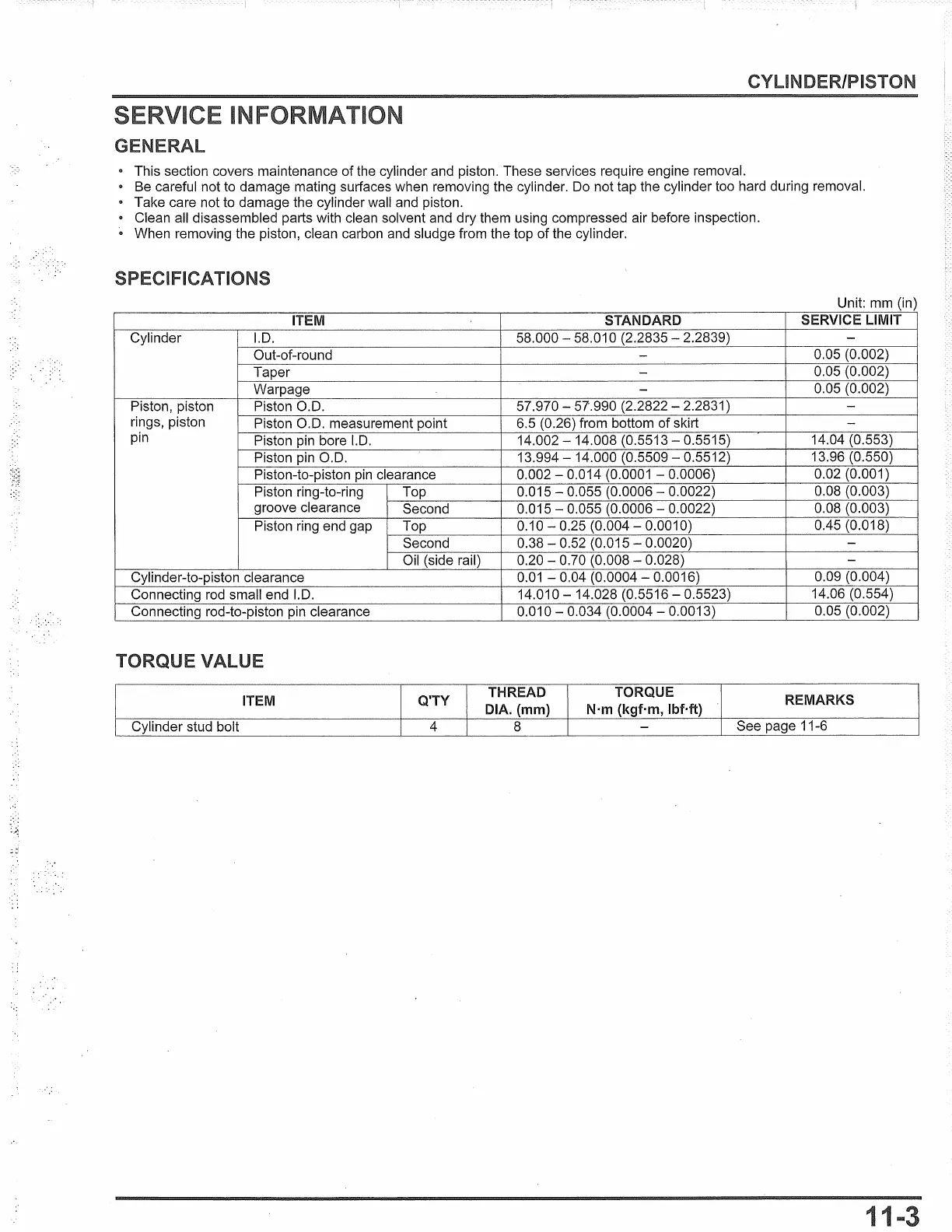

SPECIFICATIONS

Unit:

mm

(in)

ITEM

STANDARD SERVICE LIMIT

Cylinder

I.D.

58.000 - 58.010 (2.2835 - 2.2839)

-

Out-of-round

-

0.05 (0.002)

Taper

-

0.05 (0.002)

Warpage

-

0.05 (0.002)

Piston, piston Piston O.D.

57.970 - 57.990

(2.2822-2.2831)

-

rings, piston

Piston O.D. measurement point

6.5 (0.26)

from bottom of skirt

-

pin

Piston pin bore

I.D.

14.002 - 14.008 (0.5513 - 0.5515)

14.04 (0.553)

Piston pin O.D.

13.994-14.000

(0.5509-

0.5512) 13.96 (0.550)

Piston-to-piston

pin

clearance

0.002 - 0.014 (0.0001 - 0.0006) 0.02 (0.001)

Piston ring-to-ring Top

0.015 - 0.055 (0.0006 - 0.0022)

0.08 (0.003)

groove clearance

Second

0.015 - 0.055 (0.0006 - 0.0022)

0.08 (0.003)

Piston ring end gap

Top

0.10 - 0.25 (0.004 - 0.0010)

0.45 (0.018)

Second

0.38 - 0.52 (0.015 - 0.0020)

-

Oil (side rail)

0.20 - 0.70 (0.008 - 0.028)

-

Cylinder-to-piston clearance

0.01 - 0.04 (0.0004 - 0.0016) 0.09 (0.004)

Connecting rod small end I.D.

14.010-

14.028 (0.5516 - 0.5523) 14.06 (0.554)

Connecting rod-to-piston pin clearance

0.010 - 0.034 (0.0004 - 0.0013) 0.05 (0.002)

TORQUE VALUE

ITEM

Q'TY

THREAD TORQUE

REMARKS

DIA. (mm) N·m (kgf-m,

lbMt)

Cylinder stud bolt

4

8

-

See page

11-6

11

Loading...

Loading...