CYLINDER/PISTON

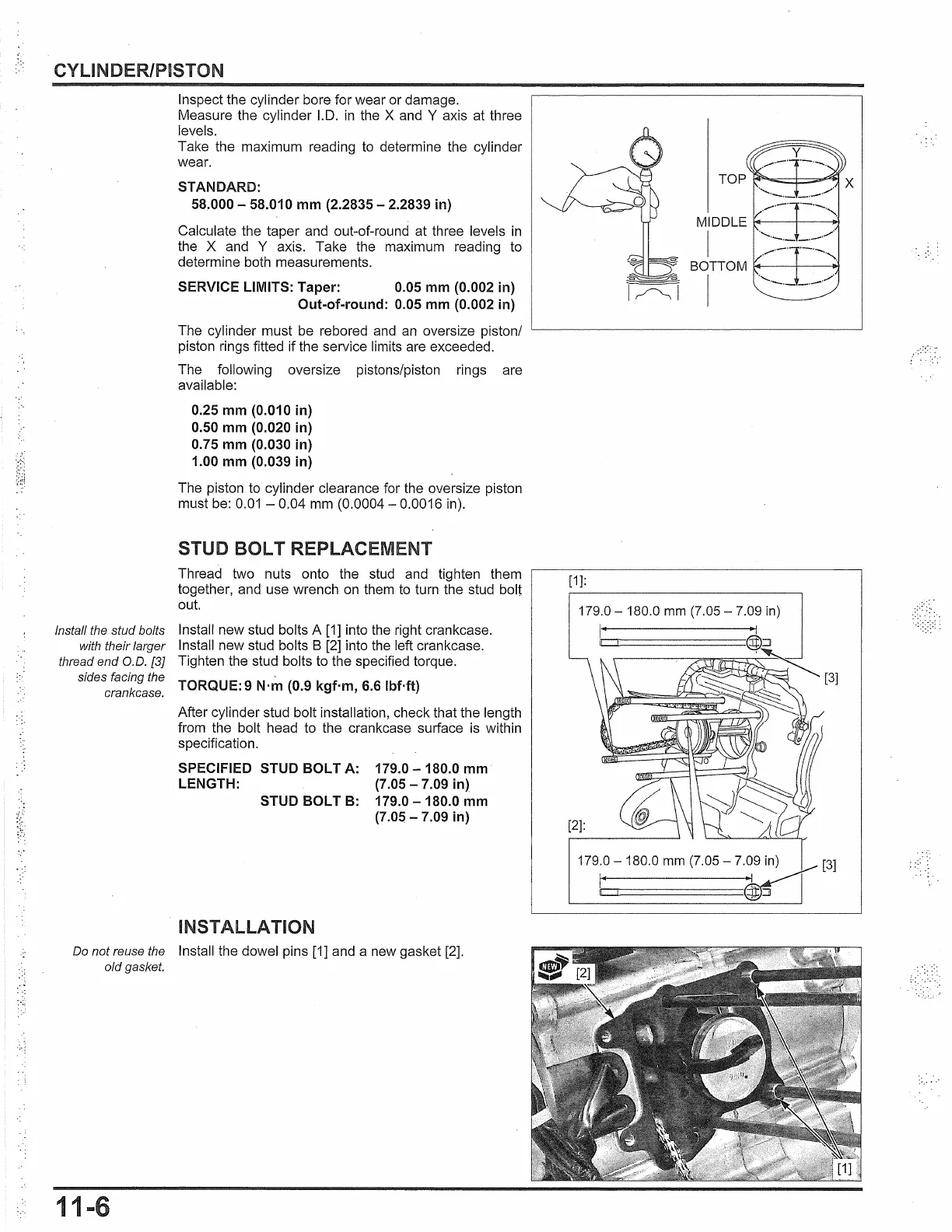

Inspect the cylinder bore for wear or damage.

Measure the cylinder I.D.

in

the X

and

Y axis at three

levels.

Take the maximum reading

to

determine the cylinder

wear.

STANDARD:

58.000 - 58.01 O mm (2.2835 - 2.2839 in)

Calculate the taper and out-of-round at three levels

in

the X and Y axis. Take the maximum reading

to

determine both measurements.

SERVICE LIMITS: Taper: 0.05 mm (0.002 in)

Out-of-round: 0.05 mm (0.002 in)

The cylinder must

be

rebored

and

an

oversize piston/

piston rings fitted if the service limits are exceeded.

The following oversize pistons/piston rings are

available:

0.25 mm (0.010 in)

0.50 mm (0.020 in)

0.75 mm (0.030 in)

1.00 mm (0.039 in)

The piston

to

cylinder clearance for the oversize piston

must

be:

0.01 - 0.04

mm

(0.0004 - 0.0016 in).

STUD BOLT REPLACEMENT

Thread two nuts onto the stud

and

tighten them

together, and use wrench

on

them

to

turn the stud bolt

out.

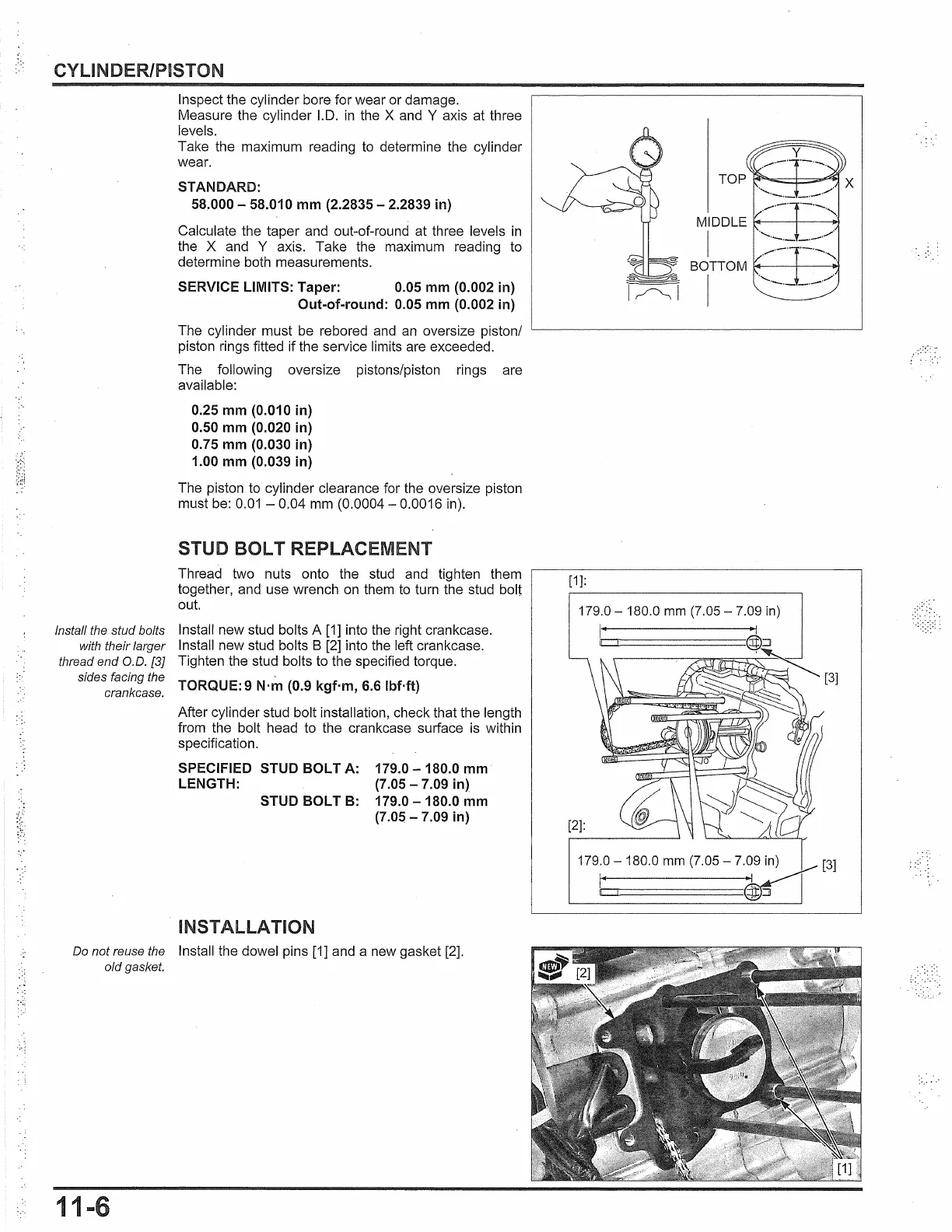

Install the stud bolts Install new stud bolts A

[1]

into the right crankcase.

with their larger Install new stud bolts B [2] into the left crankcase.

thread

end

o.o.

[3] Tighten the stud bolts to the specified torque.

sides facing the TORQUE: 9 N·m (0.9 kgf·m, 6.6

lbHt)

crankcase.

After cylinder stud bolt installation, check that the length

from the bolt head

to

the crankcase surface

is

within

specification.

SPECIFIED STUD BOLT A: 179.0 - 180.0 mm

LENGTH: (7.05 - 7.09 in)

STUD BOLT

B:

179.0 - 180.0 mm

(7.05 - 7.09 in)

INSTALLATION

Do

not

reuse the Install the dowel pins

[1]

and a new gasket

[2].

old gasket.

11-6

MI

ODLE

1<11---1----

1

BOTTOM'""--!--__...,

1~1

I

[1

]:

179.0-

180.0

mm

(7.05-

7.09

in)

I

[2]:

179.0 - 180.0

mm

(7.05 - 7.~9

~'/

[3]

..._._

______

~

I

.··.

··.· .

Loading...

Loading...