7.3 FUSE REPLACEMENT

7.3.1 Line Fuse

A rear panel fuse protects the power line input of the instru-

ment. Use the following procedure to replace the line fuse:

WARNING

Disconnect the instrument from the power

line and other equipment before replacing

the fuse.

With the power off, place the end of a flat-blade screw-

driver into the slot in the rear panel LINE FUSE holder.

Push in gently and rotate the fuse carrier one-quarter turn

counterclockwise. Release pressure on the holder and its

Internal spring will push the fuse and carrier out of the

holder.

Remove the fuse and replace it with the type recommended

in Table 7-2.

CAUTION

Do not use a fuse with a higher current

rating than specified, or instrument

damage may occur. If the instrument re-

peatedly blows fuses, locate and correct

the Cause of the trouble before replacing

the fuse.

Install the new fuse and the fuse carrier into the holder by

reversing the above procedure.

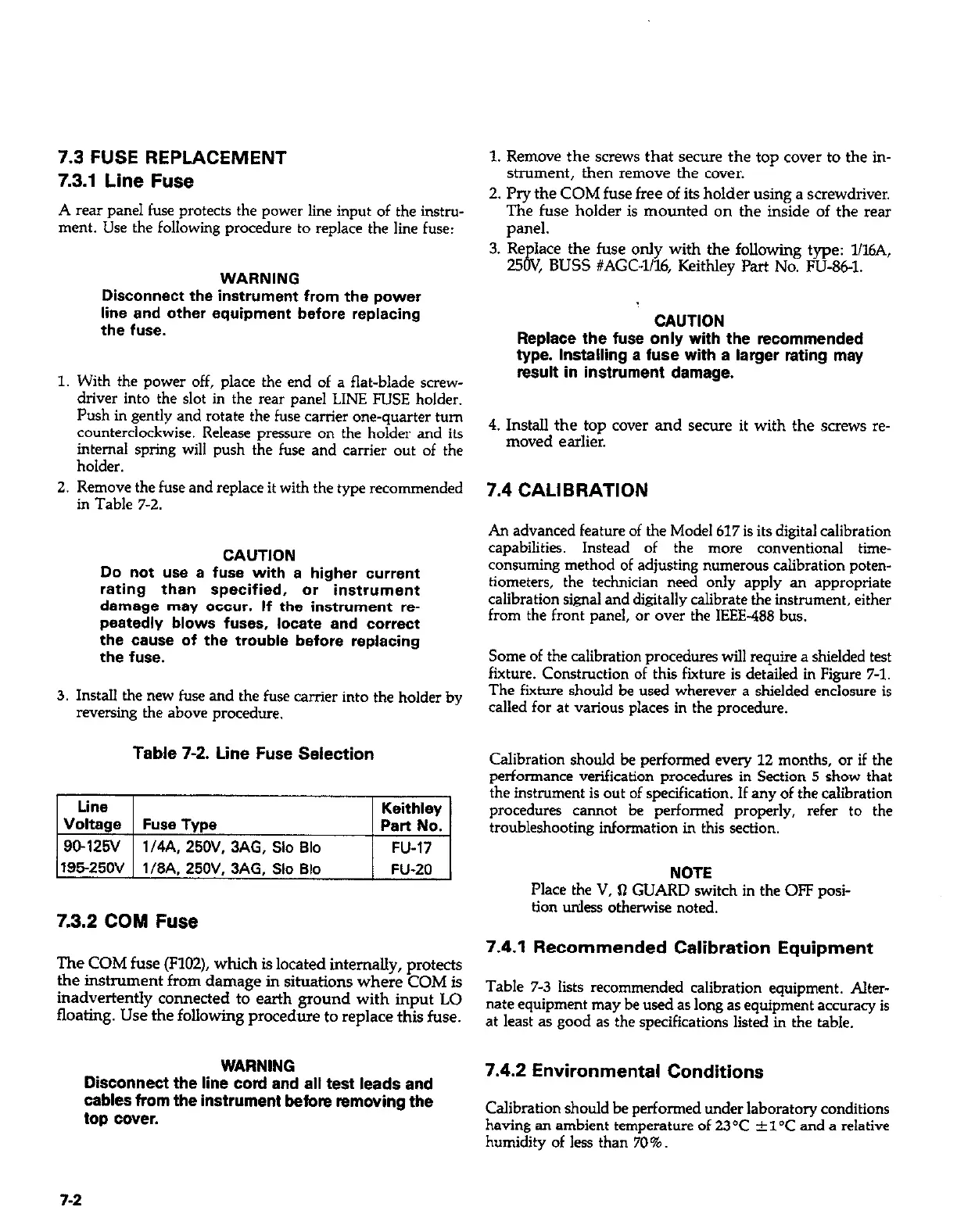

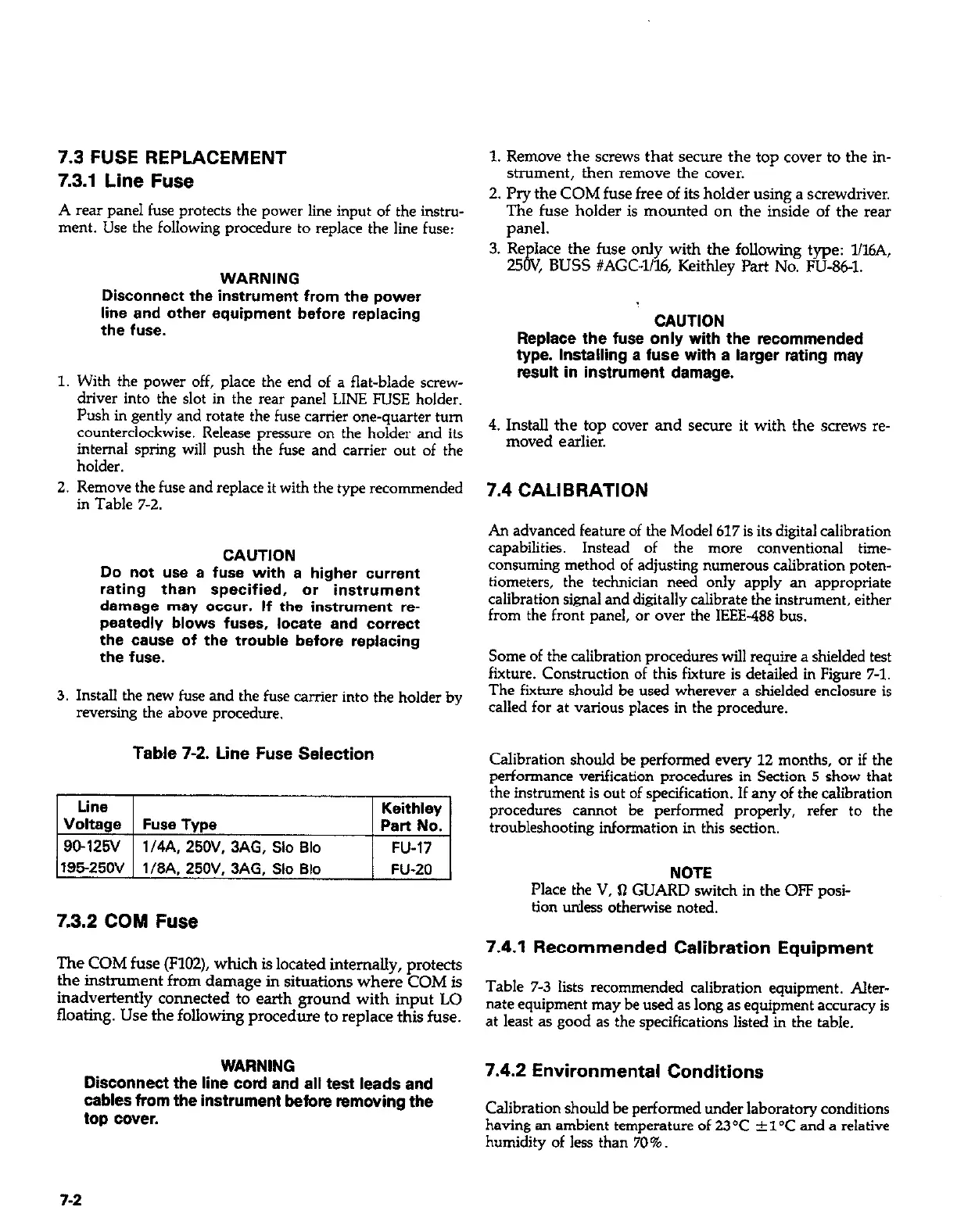

Table 7-2. Line Fuse Selection

Line

Voltage Fuse Type

90-125V 1/4A, 25OV. 3AG, Slo Blo

Keithley

Part No.

FU-17

19525OV 1/8A. 25OV. 3AG, Slo Blo

FU-20

NOTE

7.3.2 COM Fuse

The COM fuse (F102), which is located internally, protects

the instrument from damage in situations where COM is

inadvertently connected to earth ground with input LO

floating. Use the following procedure to replace this fuse.

WARNING

Disconnect the line cotd and all test leads and

cables from the instrument before removing the

top cover.

1. Remove the screws that secure the top cover to the in-

strument, then remove the cover.

2. Pry the COM fuse free of its holder using a screwdriver.

The fuse holder is mounted on the inside of the rear

panel.

3. Replace the fuse only with the following type: l&A,

25OV, BUSS #AGC-1116, Keithley Part No. FIJ-86-l.

CAUTION

Replace the fuse only with the recommended

type. Installing a fuse with a larger rating may

result in instrument damage.

4. Install the top cover and secure it with the screws re-

moved earlier.

7.4 CALIBRATION

An advanced feature of the Model 617 is its digital calibration

capabilities. Instead of the more conventional time-

consuming method of adjusting numerous calibration poten-

tiometers, the technician need only apply an appropriate

calibration signal and digitally calibrate the instrument, either

from the front panel, or over the IEEE-488 bus.

Some of the calibration procedures will require a shielded test

fixture. Construction of this fixture is detailed in Figure 7-1.

The fixture should be used wherever a shielded enclosure is

called for at various places in the procedure.

Calibration should be performed every 12 months, or if the

performance verification procedures in Section 5 show that

the instrument is out of specification. If any of the calibration

procedures cannot be performed properly, refer to the

troubleshooting information in this section.

Place the V, Q GUARD switch in the OFF posi-

tion unless otherwise noted.

7.4.1 Recommended Calibration Equipment

Table 7-3 lists recommended calibration equipment. Alter-

nate equipment may be used as long as equipment accuracy is

at least as good as the specifications listed in the table.

7.4.2 Environmental Conditions

Calibration should be performed under laboratory conditions

having an ambient temperature of 23°C kl”C and a relative

humidity of less than 70%

7-2

Loading...

Loading...