NRFD (Not Ready For Data&The acceptor controls the state

of NRFD. It is used to signal to the transmitting device to hold

off the byte transfer sequence.

NDAC (Not Data Accepted)-NDAC is also controlled by

the accepting device.

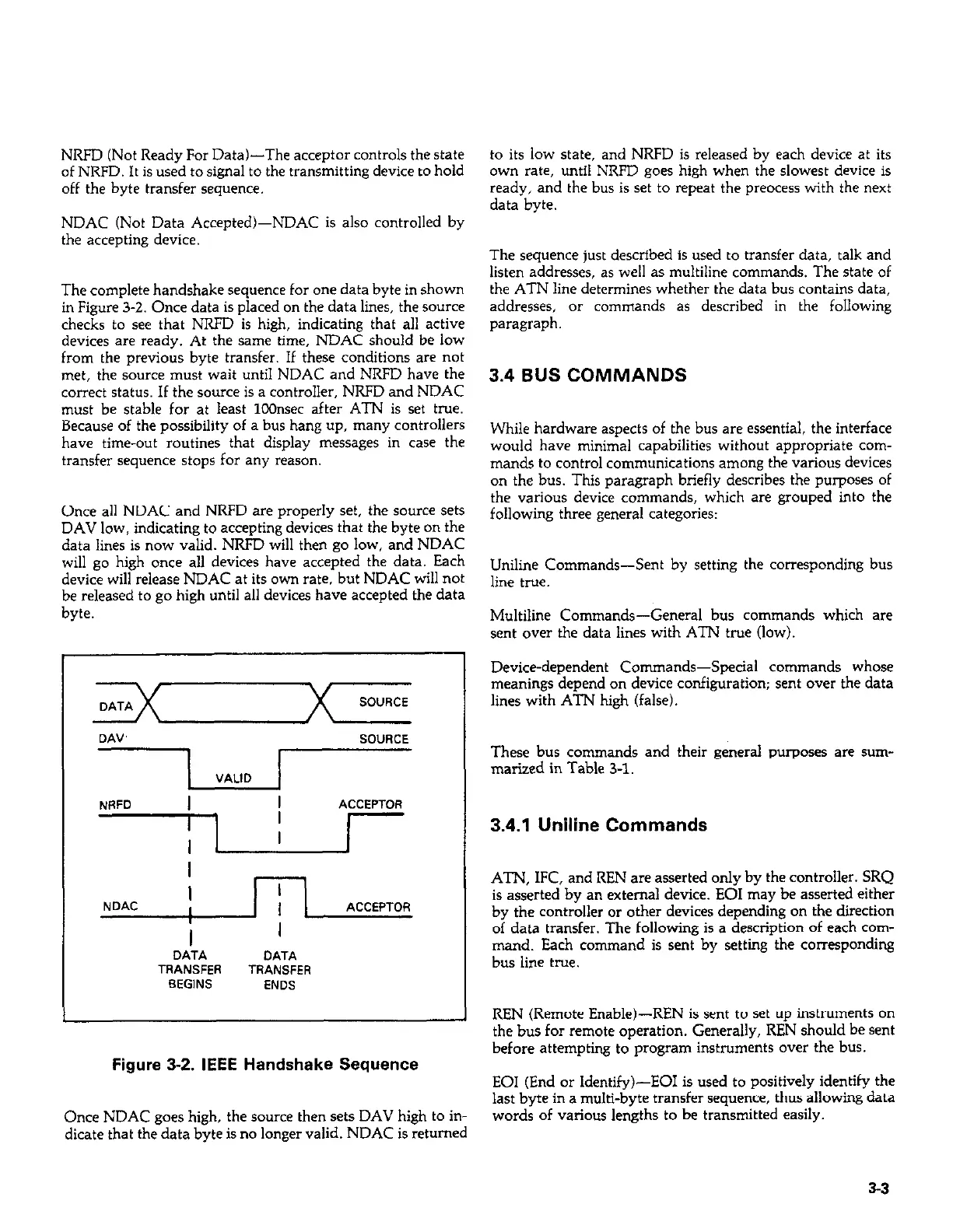

The complete handshake sequence for one data byte in shown

in Figure 3-Z. Once data is placed on the data lines, the source

checks to see that NRFD is high, indicating that all active

devices are ready. At the same time, NDAC should be low

from the previous byte transfer. If these conditions are not

met, the source must wait until NDAC and NRFD have the

correct status. If the source is a controller, NRFD and NDAC

must be stable for at least 1OOnsec after ATN is set true.

Because of the possibility of a bus hang up, many controllers

have time-out routines that display messages in case the

transfer sequence stops for any reason.

Once all NDAC and NRFD are properly set, the source sets

DAV low, indicating to accepting devices that the byte on the

data lines is now valid. NRFD will the” go low, and NDAC

will go high once all devices have accepted the data. Each

device will release NDAC at its own rate, but NDAC will not

be released to go high until all devices have accepted the data

byte

DA”’

SOURCE

VALID

NRFD

ACCEPTOR

I

I

I

I

I

NDAC

I

ACCEPTOR

,

I

I

DATA

DATA

TRANSFER

TRANSFER

BEGINS

ENDS

Figure 3-2. IEEE Handshake Sequence

Once NDAC goes high, the source then sets DAV high to in-

dicate that the data byte is no longer valid. NDAC is returned

to its low state, and NRFD is released by each device at its

own rate, until NRFD goes high when the slowest device is

ready, and the bus is set to repeat the preocess with the next

data byte.

The sequence just described is used to transfer data, talk and

listen addresses, as well as multiline commands. The state of

the ATN line determines whether the data bus contains data,

addresses, or commands as described in the following

paragraph.

3.4 BUS COMMANDS

While hardware aspects of the bus are essential, the interface

would have minimal capabilities without appropriate com-

mands to control communications among the various devices

on the bus. This paragraph briefly describes the purposes of

the various device commands, which are grouped into the

following three general categories:

Uniline Commands-Sent by setting the corresponding bus

line true.

Multiline Commands-General bus commands which are

sent over the data lines with ATN true (low).

Device-dependent Commands-Special commands whose

meanings depend on device configuration; sent over the data

lines with ATN high (false).

These bus commands and their general purposes are surn-

marized in Table 3-l.

3.4.1 Uniline Commands

ATN, IFC, and REN are asserted only by the controller. SRQ

is asserted by a” external device. EOI may be asserted either

by the controller or other devices depending on the direction

of data transfer. The following is a description of each com-

mand. Each command is sent by setting the corresponding

bus line true.

REN (Remote Enable)-REN is sent to set up instruments on

the bus for remote operation. Generally, REN should be sent

before attempting to program instruments over the bus.

EOI (End or Identify&E01 is used to positively identify the

last byte in a multi-byte transfer sequence, thus allowing data

words of various lengths to be transmitted easily.

53

Loading...

Loading...