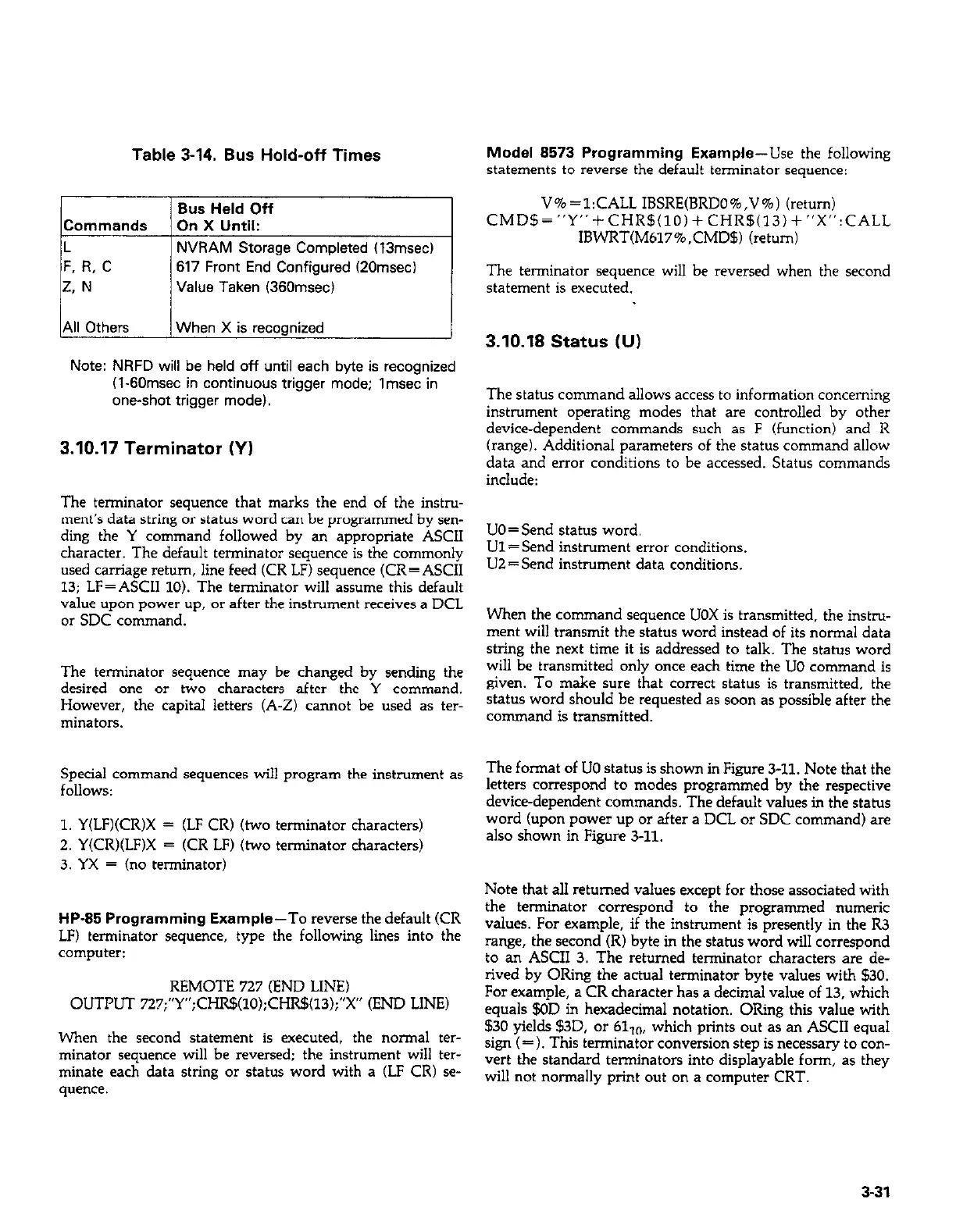

Table 3-14. Bus Hold-off Times

Model 8573 Programming Example-Use the following

statements to reverse the default terminator sequence:

Bus Held Off

V%=l:CALL IBSRE(BRDO%,V%) (return)

Commands On X Until:

CMD!§=“Y”+CHR$(lO)+CHR$(13)+“X”:CALL

L

NVRAM Storage Completed (13msec)

IBWRT(M617%,CMD$) (return)

F. R, C

617 Front End Configured (20msecl

2. N

Value Taken (36Omsec)

The terminator sequence will be reversed when the second

statement is executed.

All Others

When X is recognized

3.10.18 Status NJ)

Note: NRFD will be held off until each byte is recognized

(1.60msec in continuous trigger mode; Imsec in

one-shot trigger model.

The status command allows access to information concerning

instrument ooeratinz modes that are controlled bv other

device-dependent c&mands such as F (functionj’and R

3.10.17 Terminator (Y)

(range). Additional parameters of the status command allow

data and error conditions to be accessed. Status commands

include:

The terminator sequence that marks the end of the instru-

ment’s data string or status word can be programmed by sen-

ding the Y command followed by an appropriate ASCII

UO=Send status word.

character. The default terminator sequence is the commonly

Ul=Send instrument error conditions.

used carriage return, line feed (CR LF) sequence (CR=ASCII

UZ=Send instrument data conditions.

13: LF=ASCII 10). The terminator will assume this default

value upon power’up, or after the instrument receives a DCL

or SDC command.

When the command sequence UOX is transmitted. the instru-

ment will transmit the status word instead of its normal data

string the next time it is addressed to talk. The status word

The terminator sequence may be changed by sending the

will be transmitted only once each time the UO command is

desired one or two characters after the Y command.

given. To make sure that correct status is transmitted, the

However, the capital letters (A-Z) cannot be used as ter-

status word should be requested as soon as possible after the

minators.

command is transmitted.

Special command sequences will program the instrument as

The format of UO status is shown in Figure 3-11. Note that the

follows:

letters correspond to modes programmed by the respective

device-dependent commands. The default values in the status

1. Y(LF)(CR)X = (LF CR) (two terminator characters)

2. Y(CR)(LF)X = (CR LF) (two terminator characters)

word (upon power up or after a DCL or SDC command) are

also shown in Figure 3-11.

3. YX = (no terminator)

Note that al1 returned values except for those associated with

HP-85 Programming Example-To reverse the default (CR

the terminator correspond to ihe programmed numeric

LF) terminator sequence, type the following lines into the

values. For example, if the instrument is presently in the R3

computer:

range, the second (R) byte in the statLls word will correspond

to an ASCII 3. The returned terminator characters are de-

REMOTE 727 (END LINE)

rived by ORing the actual terminator byte values with $30.

OUTPUT 727;“Y”;CHR$(lO);CHR!§(l3);“X” (END LINE)

For example, a CR character has a decimal value of 13, which

equals $OD in hexadecimal notation. ORing this value with

When the second statement is executed, the normal ter-

$30 yields $3D, or 6110, which prints out as an ASCII equal

minator sequence will be reversed; the instrument will ter-

sign (= ). This terminator conversion step is necessary to con-

minate each data string or status word with a (LF CR) se-

vert the standard terminators into displayable form, as they

will not normally print out on a computer CRT.

quence.

3-31

Loading...

Loading...