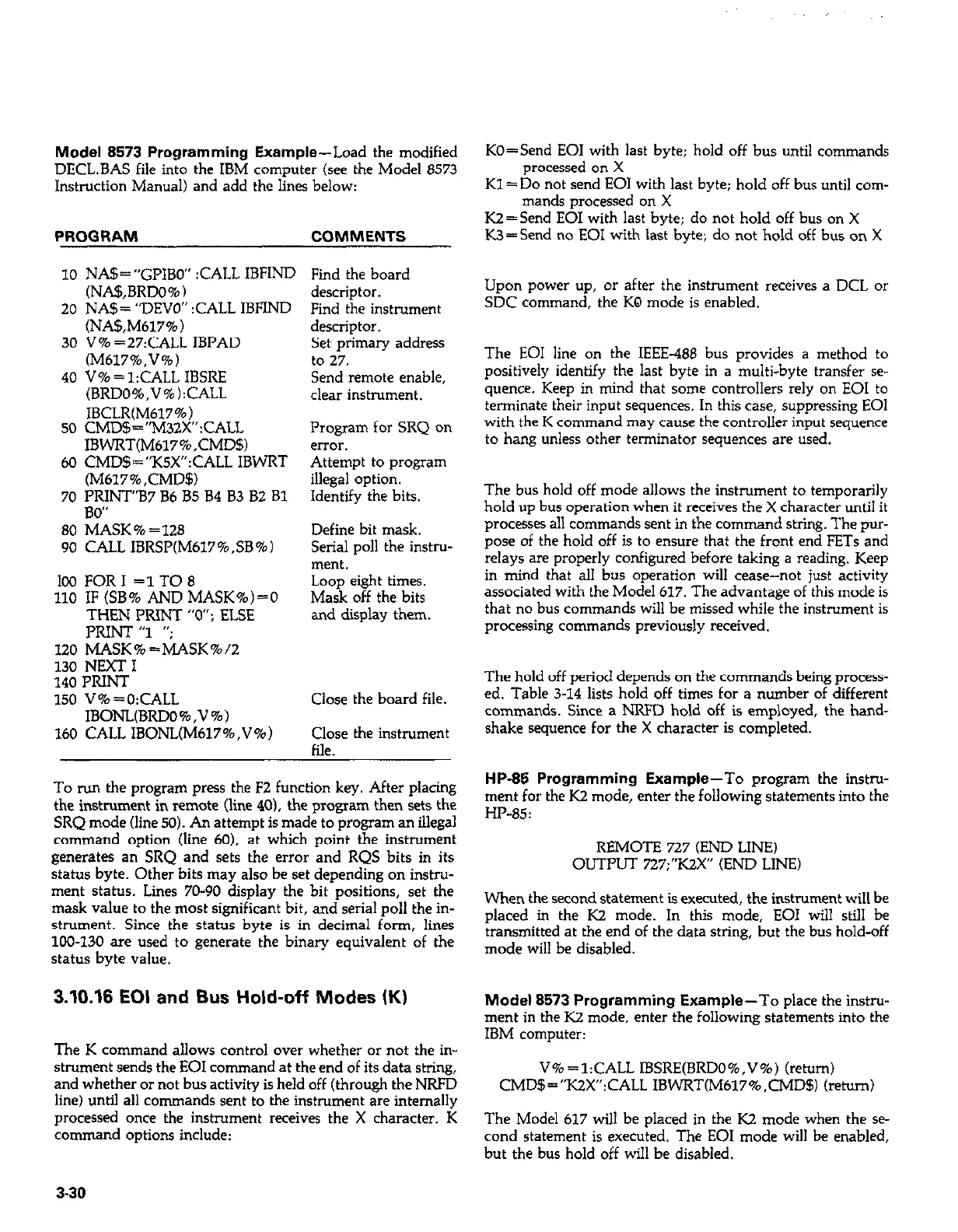

Model 8573 Programming Example-Load the modified

DECL.BAS file into the IBM computer (see the Model 8573

Instruction Manual) and add the lines below:

PROGRAM COMMENTS

10 NA$=“GPIBO” :CALL IBFIND Find the board

(NA$,BRDO%) descriptor.

20 NA$= “DEVO” :CALL IBFIND Find the instrument

(NAS,M617% ) descriutor.

30 V% =27:CALi IBPAD

(M617%,V%)

40 V% = l:CALL IBSRE

(BRDO%,V%):CALL

Set phmary address

to 27.

Send remote enable,

clear instrument.

IBCLR(M617%)

50 CMDS = “M32X” :CALL

IBWRT(M617%,CMD$l

60 CMD$=“KSX”:CALL IBWRT

(M617%,CMD$l

70 PRINT”B7 B6 B5 B4 83 B2 Bl

80”

80 MASK % = 128

90 CALL IBRSP(M617%,SB%)

100 FORI =1TO8

110 IF (SB% AND MASK%)=0

THEN PRINT “0”; ELSE

PRINT “1 “;

120 MASK%=MASK%/2

130 NEXT I

Program for SRQ on

aTor.

Attempt to program

illegal option.

Identify the bits.

Define bit mask.

Serial poll the instm-

merit.

Loop eight times.

Mask off the bits

and display them.

140 PRINT

150 V% =O:CALL

IBONL(BRDO%,V%)

Close the board file.

160 CALL IBONL(M617%,V%) Close the instrument

file.

To run the program press the F2 function key. After placing

the instrument in remote (line 40). the program then sets the

SRQ mode (line 50). An attempt is made to program an illegal

command option (line 60). at which point the instrument

generates an SRQ and sets the error and RQS bits in its

status byte. Other bits may also be set depending on instru-

ment status. Lines 70-90 display the bit positions, set the

mask value to the most significant bit, and serial poll the in-

strument. Since the status byte is in decimal form, lines

100-130 are used to generate the binary equivalent of the

status byte value.

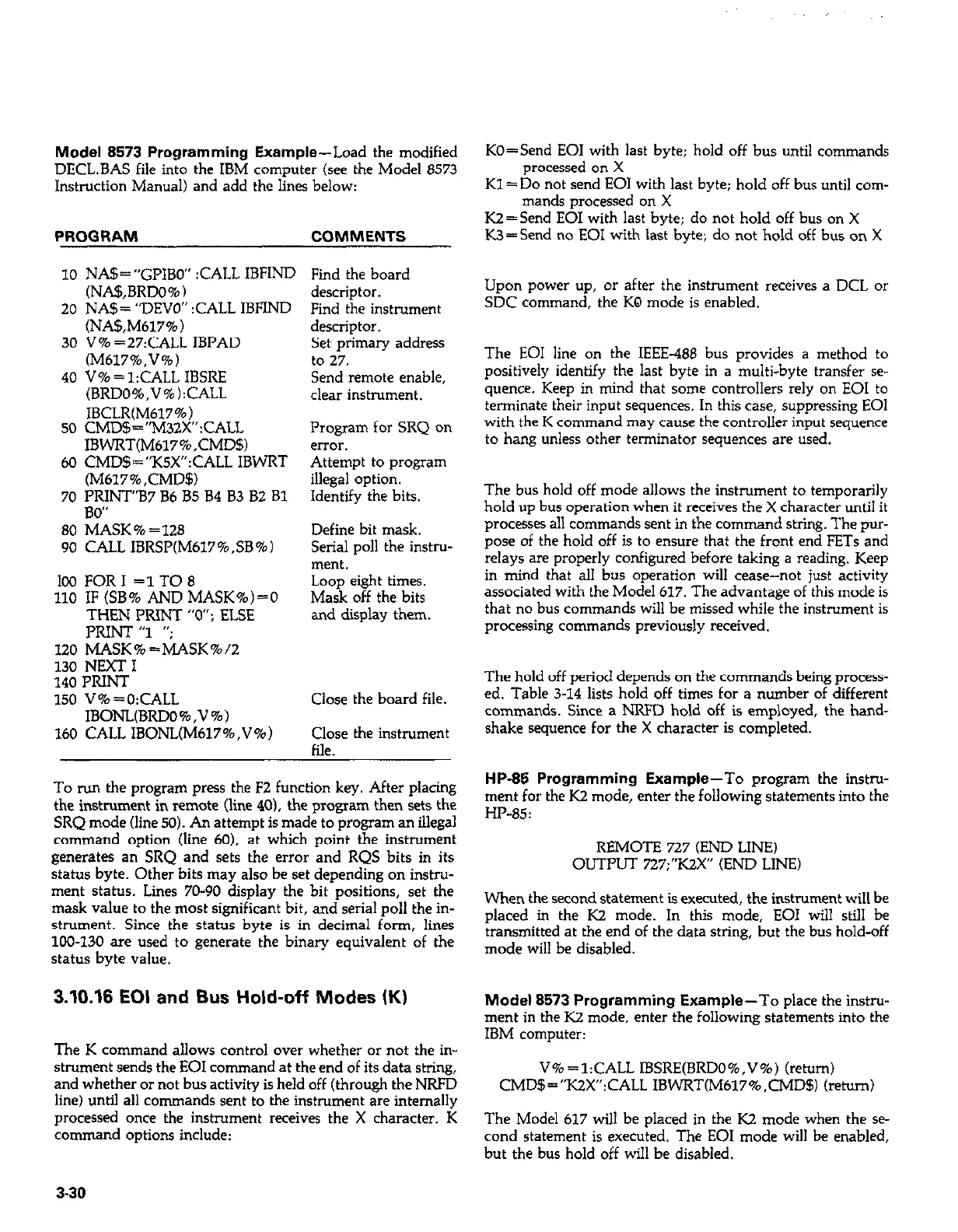

KO=Send EOI with last byte; hold off bus until commands

processed on X

Kl=Do not send EOI with last byte; hold off bus until com-

mands processed on X

K2=Send EOI with last byte; do not hold off bus on X

IW=Send no EOI with last byte; do not hold off bus on X

Upon power up, or after the instrument receives a DCL or

SDC command, the KQ mode is enabled.

The EOI line on the IEEE-486 bus provides a method to

positively identify the last byte in a multi-byte transfer se-

quence. Keep in mind that some controllers rely on EOI to

terminate their input sequences. In this case, suppressing EOI

with the K command may cause the controller input sequence

to hang unless other terminator sequences are used.

The bus hold off mode allows the instrument to temporarily

hold up bus operation when it receives the X character until it

processes all commands sent in the command string. The pur-

pose of the hold off is to ensure that the front end FETs and

relays are properly configured before taking a reading. Keep

in mind that all bus operation will cease-not just activity

associated with the Model 617. The advantage of this mode is

that no bus commands will be missed while the instrument is

processing commands previously received.

The hold off period depends on the commands being process-

ed. Table 3-14 lists hold off times for a number of different

commands. Since a NRFD hold off is employed, the hand-

shake sequence for the X character is completed.

HP-85 Programming Example-To program the instm-

ment for the K2 mode, enter the following statements into the

HP-85:

REMOTE 727 (END LINE)

OUTPUT 727;“K2x” (END LINE)

When the second statement is executed, the instrument will be

placed in the K2 mode. In this mode, EOI will still be

transmitted at the end of the data string, but the bus hold-off

mode will be disabled.

3.10.16 EOI and Bus Hold-off Modes (K)

Model 8573 Programming Example-To place the instm-

ment in the K2 mode, enter the following statements into the

IBM computer:

The K command allows control over whether or not the in-

strument sends the EOI command at the end of its data string,

V%=l:CALL IBSRE(BRDO%,V%) (return)

and whether or not bus activity is held off (through the NRFD

CMD$=“KZX”:CALL IBWRT(M617%,CMD$) (retom)

line) until all commands sent to the instrument are internally

processed once the instrument receives the X character. K

command options include:

The Model 617 will be placed in the K2 mode when the se-

cond statement is executed. The EOI mode will be enabled,

but the bus hold off will be disabled.

3-30

Loading...

Loading...